MOKI RADIAL Care and Maintenence

#5126

Junior Member

Hello everyone.

I’m new here, as I haven’t been active for about a decade, but I’m back now, seeking all the Moki knowledge I can soak up from this knowledgeable group.

I have a NIB MOKI 150 Radial which I bought 20 years ago from RC Showcase for a project that I will finally be starting. However, now I see there no longer seems to be any support or parts for this engine.

Among many things I need intel on (fuel pumps, newer ignition, etc), I’m wondering if there is any commonality of wear item parts (like valve springs, pushrods, rockers, gaskets) between the 150cc Moki and perhaps the Moki 180?

My puny contribution for now… and pardon me if this contribution is repetitive, but regarding Olivier Rogeau‘s French language YT series: His videos made a LOT more sense to me once I enabled CAPTIONS>TRANSLATE>ENGLISH. I was amazed at the apparent accuracy of the instant Google translation.

I’m new here, as I haven’t been active for about a decade, but I’m back now, seeking all the Moki knowledge I can soak up from this knowledgeable group.

I have a NIB MOKI 150 Radial which I bought 20 years ago from RC Showcase for a project that I will finally be starting. However, now I see there no longer seems to be any support or parts for this engine.

Among many things I need intel on (fuel pumps, newer ignition, etc), I’m wondering if there is any commonality of wear item parts (like valve springs, pushrods, rockers, gaskets) between the 150cc Moki and perhaps the Moki 180?

My puny contribution for now… and pardon me if this contribution is repetitive, but regarding Olivier Rogeau‘s French language YT series: His videos made a LOT more sense to me once I enabled CAPTIONS>TRANSLATE>ENGLISH. I was amazed at the apparent accuracy of the instant Google translation.

#5127

Hello everyone.

I’m new here, as I haven’t been active for about a decade, but I’m back now, seeking all the Moki knowledge I can soak up from this knowledgeable group.

I have a NIB MOKI 150 Radial which I bought 20 years ago from RC Showcase for a project that I will finally be starting. However, now I see there no longer seems to be any support or parts for this engine.

Among many things I need intel on (fuel pumps, newer ignition, etc), I’m wondering if there is any commonality of wear item parts (like valve springs, pushrods, rockers, gaskets) between the 150cc Moki and perhaps the Moki 180?

My puny contribution for now… and pardon me if this contribution is repetitive, but regarding Olivier Rogeau‘s French language YT series: His videos made a LOT more sense to me once I enabled CAPTIONS>TRANSLATE>ENGLISH. I was amazed at the apparent accuracy of the instant Google translation.

I’m new here, as I haven’t been active for about a decade, but I’m back now, seeking all the Moki knowledge I can soak up from this knowledgeable group.

I have a NIB MOKI 150 Radial which I bought 20 years ago from RC Showcase for a project that I will finally be starting. However, now I see there no longer seems to be any support or parts for this engine.

Among many things I need intel on (fuel pumps, newer ignition, etc), I’m wondering if there is any commonality of wear item parts (like valve springs, pushrods, rockers, gaskets) between the 150cc Moki and perhaps the Moki 180?

My puny contribution for now… and pardon me if this contribution is repetitive, but regarding Olivier Rogeau‘s French language YT series: His videos made a LOT more sense to me once I enabled CAPTIONS>TRANSLATE>ENGLISH. I was amazed at the apparent accuracy of the instant Google translation.

Jugman,

dont worry too much.

The 150 and 180 are pretty much identical except piston diameter.

Most of the 180 parts will fit in the 150, and normally, you dont need much spare parts if you care for your engine well.

#5128

My Feedback: (2)

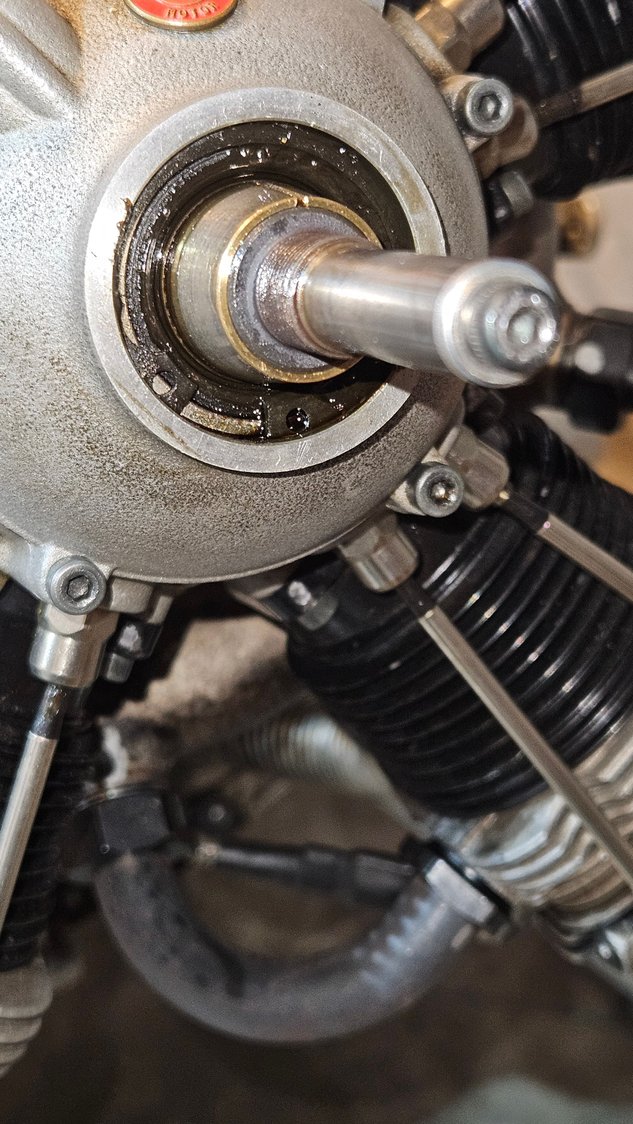

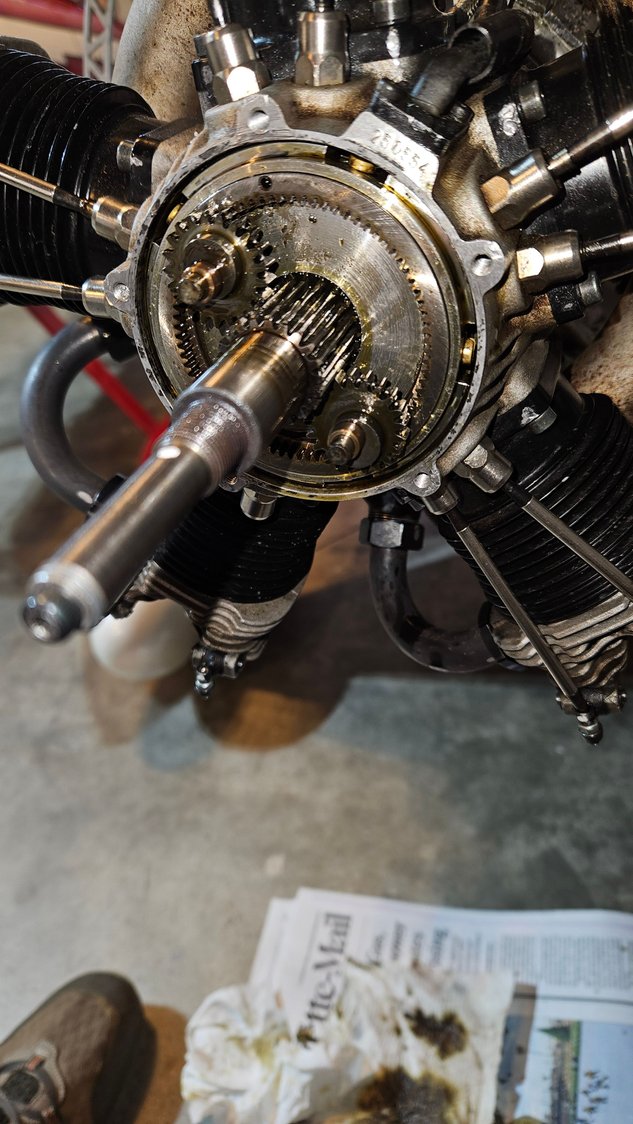

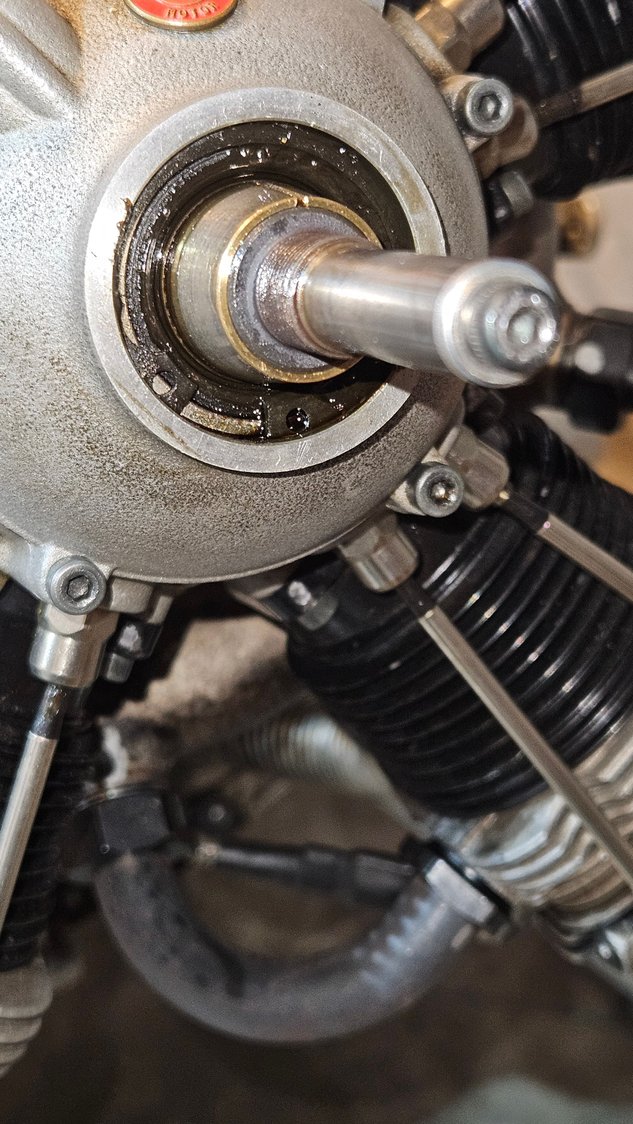

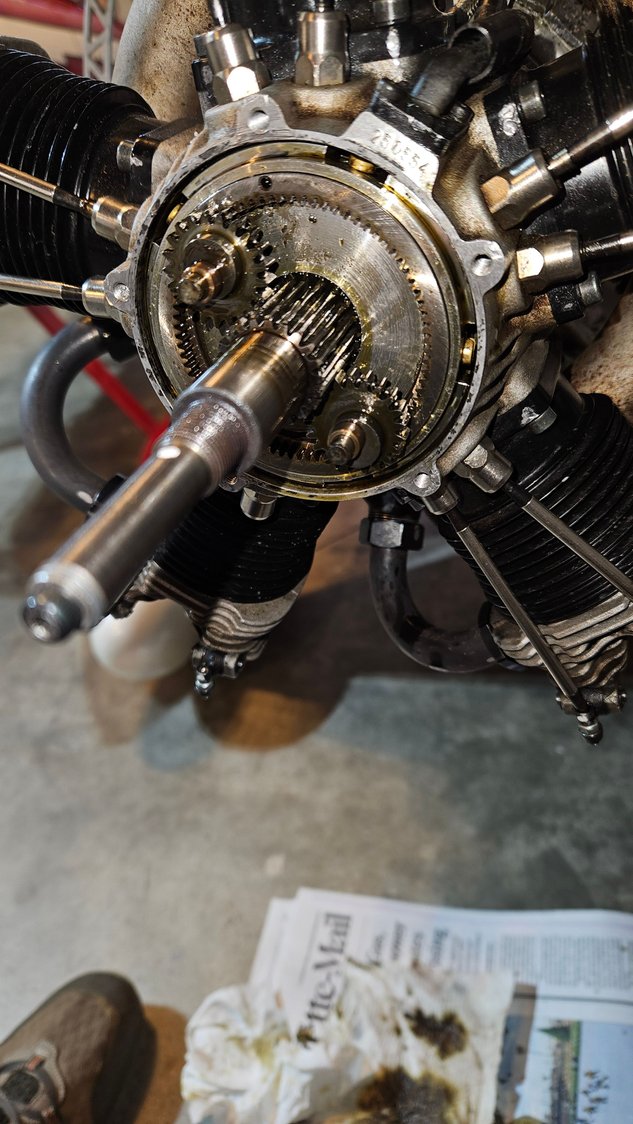

My older Moki 250 (about 2010) had hundreds of flights. Today was the day (1st time) to pull the front gear case to inspect and replace the cam and gears. For the past 3-4 years I've been injecting 85W-140 gear oil through the top lifter to replenish the cam/gear grease. To my surprise almost all of the old factory (blue) grease was dissolved after being replaced by the thinner 85w-140 gear oil. Inspection of the gears and teeth revealed little to no wear. After seeing this, I would be confident to continue lubing the gears with the gear oil. However, for the sake of less maintenance, I'll be repacking the case with the factory blue grease. After 2-3 more flying seasons I'll resume injecting gear oil in the case. Now comes the questions please. The front gear housing has a thin O-ring and is coated with a white elastic sealant.

What is the sealant or - what is a suitable product to seal the case upon reassembly?

Should I replace the O-ring and/or front bearing seal?

Thanks - J Tab

What is the sealant or - what is a suitable product to seal the case upon reassembly?

Should I replace the O-ring and/or front bearing seal?

Thanks - J Tab

#5129

Jake,

good example that you show here. Oil goes everywhere- and does its job.

With grease, you cannot be so sure.

I had more than one squeeking engine here with dry cams (!)

After a couple of years on the engine , I would always replace the Oring. It settles with the years and loses its ability to seal the case.

Normally, you then dont need extra sealant, although factory new enginge also have this "double safety ( sealing plus sealant)

If you want to add sealant, use any soft engine sealant like this here:

good example that you show here. Oil goes everywhere- and does its job.

With grease, you cannot be so sure.

I had more than one squeeking engine here with dry cams (!)

After a couple of years on the engine , I would always replace the Oring. It settles with the years and loses its ability to seal the case.

Normally, you then dont need extra sealant, although factory new enginge also have this "double safety ( sealing plus sealant)

If you want to add sealant, use any soft engine sealant like this here:

#5130

My Feedback: (2)

Detlef - Thank you. Before I removed the planetary gears completely, I marked a point on the top gear where it merged with the shaft to prevent getting the gear out of sync. The shaft was positioned so that the timing mark and #1 is at TDC. I removed the gear and attempted to reinstall in different locations. I found that the gear could be reinstalled 2-3 teeth either side of the mark at the original position. At this point I am reluctant to remove the gears and cam ring and not be able to reinstall at the correct timing locations. Following the video #5 from Oliver Rogeau, I must be doing something wrong.

It's probably safer for me to not remove the gears and cam ring. I'll give it a day or 2 to sleep on and then inject the factory SKF Bearing grease from the lifter holes in the top.

Any other suggestions.

Thanks, and regards - J Tab

It's probably safer for me to not remove the gears and cam ring. I'll give it a day or 2 to sleep on and then inject the factory SKF Bearing grease from the lifter holes in the top.

Any other suggestions.

Thanks, and regards - J Tab

#5131

Detlef - Thank you. Before I removed the planetary gears completely, I marked a point on the top gear where it merged with the shaft to prevent getting the gear out of sync. The shaft was positioned so that the timing mark and #1 is at TDC. I removed the gear and attempted to reinstall in different locations. I found that the gear could be reinstalled 2-3 teeth either side of the mark at the original position. At this point I am reluctant to remove the gears and cam ring and not be able to reinstall at the correct timing locations. Following the video #5 from Oliver Rogeau, I must be doing something wrong.

It's probably safer for me to not remove the gears and cam ring. I'll give it a day or 2 to sleep on and then inject the factory SKF Bearing grease from the lifter holes in the top.

Any other suggestions.

Thanks, and regards - J Tab

It's probably safer for me to not remove the gears and cam ring. I'll give it a day or 2 to sleep on and then inject the factory SKF Bearing grease from the lifter holes in the top.

Any other suggestions.

Thanks, and regards - J Tab

Jake, now I am confused.

Did you or did you not remove the gears and cam drum?

#5132

My Feedback: (2)

Detlef, sorry for the confusing paragraph. I removed the top gear only after marking the tooth location as it merges with the shaft and replaced it in the exact location. I discovered the gear could be reinstalled incorrectly by 2 teeth either side of the mark. If I remove the gears and drum completely, I'm not confident I could restore them in the correct location.

What I have done since is spray brake and evaporative cleaner behind the cam drum. That appears to have removed most if not all the older grease.

Today I'll be injecting the blue grease through the top lifter nut to lubricate behind the cam drum and then repack the front of the case.

I'm going to reuse the O Ring. In the event it needs to be replaced, the dimensions appear to be 76 mm OD and diameter of 1.5 mm. Does that sound correct?

BTW - I found Reinzosil at a local auto parts store.

Have you replaced front bearing/seal on the Moki before?

Thanks for your patience. Getting valuable input from others helps build confidence to work on this motor.

Regards - J Tab

What I have done since is spray brake and evaporative cleaner behind the cam drum. That appears to have removed most if not all the older grease.

Today I'll be injecting the blue grease through the top lifter nut to lubricate behind the cam drum and then repack the front of the case.

I'm going to reuse the O Ring. In the event it needs to be replaced, the dimensions appear to be 76 mm OD and diameter of 1.5 mm. Does that sound correct?

BTW - I found Reinzosil at a local auto parts store.

Have you replaced front bearing/seal on the Moki before?

Thanks for your patience. Getting valuable input from others helps build confidence to work on this motor.

Regards - J Tab

#5133

Detlef, sorry for the confusing paragraph. I removed the top gear only after marking the tooth location as it merges with the shaft and replaced it in the exact location. I discovered the gear could be reinstalled incorrectly by 2 teeth either side of the mark. If I remove the gears and drum completely, I'm not confident I could restore them in the correct location.

What I have done since is spray brake and evaporative cleaner behind the cam drum. That appears to have removed most if not all the older grease.

Today I'll be injecting the blue grease through the top lifter nut to lubricate behind the cam drum and then repack the front of the case.

I'm going to reuse the O Ring. In the event it needs to be replaced, the dimensions appear to be 76 mm OD and diameter of 1.5 mm. Does that sound correct?

BTW - I found Reinzosil at a local auto parts store.

Have you replaced front bearing/seal on the Moki before?

Thanks for your patience. Getting valuable input from others helps build confidence to work on this motor.

Regards - J Tab

What I have done since is spray brake and evaporative cleaner behind the cam drum. That appears to have removed most if not all the older grease.

Today I'll be injecting the blue grease through the top lifter nut to lubricate behind the cam drum and then repack the front of the case.

I'm going to reuse the O Ring. In the event it needs to be replaced, the dimensions appear to be 76 mm OD and diameter of 1.5 mm. Does that sound correct?

BTW - I found Reinzosil at a local auto parts store.

Have you replaced front bearing/seal on the Moki before?

Thanks for your patience. Getting valuable input from others helps build confidence to work on this motor.

Regards - J Tab

Yes I did replace bearings of Mokis. No rocket science. Just heaten the case to about 170 ° and they fall out or just need a very small push.

To re-insert new bearings, I go only to 125-130° celsius because the bearings are cold and the play is enough if you manage put them in place QUICKLY ( with the help of simple guides for example)

I do not like to over heat brand new bearings, they do not get better.

In case you take out the gears, just come back here. It is not too dificult if you know a few things.

Cheers

#5134

What I have experienced using the recommended APS fuel pump: My Moki 180 has been difficult to start since day one. Going against almost all past practices, I skipped any bench running and installed the new engine into my aircraft.

After two very frustrating rounds of coil replacements (see my earlier post), I finally have a reliable ignition. However, starting the engine continued to be difficult, despite my 20 years history of gas engine success (incl. Moki 250 and Saito radials) and over 40 year history of model engine experience (incl. glow radials).

And I have to say, it is unfortunate I always feel compelled to "qualify" my experience, but I assure you, I am not some model engine nitwit who immediately blames the product when I run into difficulties - quite the opposite.

The last time I flew my CARF SU-31 at an event, I posted one flight. An hour later when trying to start the engine again, no dice. After one "burp" while choked, I could never get it to even pop. Everything checked out fine and I had no interest in wrenching on the plane at the event.

The following morning, I removed the spark plugs and found the bottom two literally with pools of fuel in them. I had followed the exact same starting procedure as always - the exact same starting procedure I have used on every gasser I have ever owned, including my Moki 250 (which did NOT an external fuel pump).

After drying the plugs and swapping 1 and 2 with 3 and 4, the engine started normally and ran fine.

I have since sold the airframe to a buddy and removed the 180 with its next home being an F8F Bearcat. To that end, I mounted the Moki on my test stand and ran it with a 4 blade prop and no fuel pump. VOILA!

Now it starts with the exact same reliability as all my other gassers, using exactly the same starting routine.

With no external fuel pump, I did have to adjust the H and L speed needles, but engine starting is now 100% reliable, hot or cold. It throttles well and runs like a top. Also, I notice absolutely NO difference in the way the engine idles, throttles, or howls at full throttle without the auxiliary fuel pump.

Clearly, the APS fuel pump was FLOODING the engine.

OK, so mine is the programmable version and I never slaved it to the throttle stick. IF at some point in the future I decide I need it, I will.

After probably 20 flights on the engine with the fuel pump, combined with MANY sore arms starting the Moki, I have NO intention of installing the fuel pump into the Bearcat.

After a dozen or so bench runs there is absolutely zero residue/blockage in the air pulse pump line which actuates the internal Walbro pump diaphragm.

With my Moki 250 I did have to keep an eye on that line and clean it out perhaps every half dozen flights. The same diligence will be exercised again.

No pump vastly simplifies engine/tank installation too.

While I am NOT saying the APS pump is a bad idea, I am just describing my experience with it. Chances are, had I slaved it to the throttle channel, this starting/flooding problem may have been avoided.

BUT, I prefer what has proven to WORK for ME over the years, combined with simplicity, even if it requires extra diligence in keeping the engine's internal pump system at 100%.

After two very frustrating rounds of coil replacements (see my earlier post), I finally have a reliable ignition. However, starting the engine continued to be difficult, despite my 20 years history of gas engine success (incl. Moki 250 and Saito radials) and over 40 year history of model engine experience (incl. glow radials).

And I have to say, it is unfortunate I always feel compelled to "qualify" my experience, but I assure you, I am not some model engine nitwit who immediately blames the product when I run into difficulties - quite the opposite.

The last time I flew my CARF SU-31 at an event, I posted one flight. An hour later when trying to start the engine again, no dice. After one "burp" while choked, I could never get it to even pop. Everything checked out fine and I had no interest in wrenching on the plane at the event.

The following morning, I removed the spark plugs and found the bottom two literally with pools of fuel in them. I had followed the exact same starting procedure as always - the exact same starting procedure I have used on every gasser I have ever owned, including my Moki 250 (which did NOT an external fuel pump).

After drying the plugs and swapping 1 and 2 with 3 and 4, the engine started normally and ran fine.

I have since sold the airframe to a buddy and removed the 180 with its next home being an F8F Bearcat. To that end, I mounted the Moki on my test stand and ran it with a 4 blade prop and no fuel pump. VOILA!

Now it starts with the exact same reliability as all my other gassers, using exactly the same starting routine.

With no external fuel pump, I did have to adjust the H and L speed needles, but engine starting is now 100% reliable, hot or cold. It throttles well and runs like a top. Also, I notice absolutely NO difference in the way the engine idles, throttles, or howls at full throttle without the auxiliary fuel pump.

Clearly, the APS fuel pump was FLOODING the engine.

OK, so mine is the programmable version and I never slaved it to the throttle stick. IF at some point in the future I decide I need it, I will.

After probably 20 flights on the engine with the fuel pump, combined with MANY sore arms starting the Moki, I have NO intention of installing the fuel pump into the Bearcat.

After a dozen or so bench runs there is absolutely zero residue/blockage in the air pulse pump line which actuates the internal Walbro pump diaphragm.

With my Moki 250 I did have to keep an eye on that line and clean it out perhaps every half dozen flights. The same diligence will be exercised again.

No pump vastly simplifies engine/tank installation too.

While I am NOT saying the APS pump is a bad idea, I am just describing my experience with it. Chances are, had I slaved it to the throttle channel, this starting/flooding problem may have been avoided.

BUT, I prefer what has proven to WORK for ME over the years, combined with simplicity, even if it requires extra diligence in keeping the engine's internal pump system at 100%.

I recently purchased a used Moki 250 off a gentleman who is both veteran R/C aircraft and Mechanic in 1. He also happens to be one of the most approachable people I know. So to the Moki, I was told that the engine has very little run time but considering some aspects of it's condition I doubt this, I paid nearly half it's new value and that's the other reason for my doubts. I'm wondering if there is an easy way to determine how much run time it has without stripping the engine, my own thoughts would be to remove an exhaust port from one of the heads and see how much carbon build up there is, I don't know what exactly to do so that is why I'm asking. The other issue is that there are 2 pushrods which are bent, one is out at least 2mm the other is just minor, I have been told they can be straightened but i know that with car engines that's a big no no, i would appreciate your thoughts.

#5135

My Feedback: (2)

Hi Jake,

Yes I did replace bearings of Mokis. No rocket science. Just heaten the case to about 170 ° and they fall out or just need a very small push.

To re-insert new bearings, I go only to 125-130° celsius because the bearings are cold and the play is enough if you manage put them in place QUICKLY ( with the help of simple guides for example)

I do not like to over heat brand new bearings, they do not get better.

In case you take out the gears, just come back here. It is not too dificult if you know a few things.

Cheers

Yes I did replace bearings of Mokis. No rocket science. Just heaten the case to about 170 ° and they fall out or just need a very small push.

To re-insert new bearings, I go only to 125-130° celsius because the bearings are cold and the play is enough if you manage put them in place QUICKLY ( with the help of simple guides for example)

I do not like to over heat brand new bearings, they do not get better.

In case you take out the gears, just come back here. It is not too dificult if you know a few things.

Cheers

Your advice was spot on the mark.

My first attempt I used propane to heat the case. The bearing could not be extracted.

Second attempt, I heated the front case (with bearing) in the oven at 350F (177C) for 2 hours. The bearing popped out with minimal tap.

Tomorrow's project - freeze the bearing, reheat the case, and hope it glides in straight. I made a 35 mm x 6mm plywood disc to protect the bearing when I tap it into the case.

Question - does the bearing go in dry or lubed with grease???

Thanks - J Tab

BTW - I been told that the difficult part aligning air pump connecting ring to the cam gear.

If I remove the small air pump cylinder, I may have a better chance of connecting the ring on the cam gear.

I also have a new o ring that I will coat with silicone grease. The new o ring by itself should seal the case.

Last edited by Jaketab; 01-02-2024 at 09:24 PM.

#5136

Detlef,

Your advice was spot on the mark.

My first attempt I used propane to heat the case. The bearing could not be extracted.

Second attempt, I heated the front case (with bearing) in the oven at 350F (177C) for 2 hours. The bearing popped out with minimal tap.

Tomorrow's project - freeze the bearing, reheat the case, and hope it glides in straight. I made a 35 mm x 6mm plywood disc to protect the bearing when I tap it into the case.

Question - does the bearing go in dry or lubed with grease???

Thanks - J Tab

BTW - I been told that the difficult part aligning air pump connecting ring to the cam gear.

If I remove the small air pump cylinder, I may have a better chance of connecting the ring on the cam gear.

I also have a new o ring that I will coat with silicone grease. The new o ring by itself should seal the case.

Your advice was spot on the mark.

My first attempt I used propane to heat the case. The bearing could not be extracted.

Second attempt, I heated the front case (with bearing) in the oven at 350F (177C) for 2 hours. The bearing popped out with minimal tap.

Tomorrow's project - freeze the bearing, reheat the case, and hope it glides in straight. I made a 35 mm x 6mm plywood disc to protect the bearing when I tap it into the case.

Question - does the bearing go in dry or lubed with grease???

Thanks - J Tab

BTW - I been told that the difficult part aligning air pump connecting ring to the cam gear.

If I remove the small air pump cylinder, I may have a better chance of connecting the ring on the cam gear.

I also have a new o ring that I will coat with silicone grease. The new o ring by itself should seal the case.

To remove the air pump cylinder is - in my opinion- the only way to fumble the conrod on the excenter seat of the planetary gear.

You do that holding the tiny piston and hope to have a good day :-)

!!! be sure you mount it the right way like it came out - it is NOT symmetrical !!

#5137

My Feedback: (2)

To remove the air pump cylinder is - in my opinion- the only way to fumble the conrod on the excenter seat of the planetary gear.

You do that holding the tiny piston and hope to have a good day :-)

!!! be sure you mount it the right way like it came out - it is NOT symmetrical !!

You do that holding the tiny piston and hope to have a good day :-)

!!! be sure you mount it the right way like it came out - it is NOT symmetrical !!

Yes, I noticed that the piston is offset. I've already experimented with reinstalling it.

I'm thinking of omitting the piston for 3 reasons.

1. I use the electric pump.

2. The piston connecting rod is difficult to place over the cam gear.

3. Most importantly, in the future by simply removing the pump cylinder housing will give excellent access to refresh the grease, which would allow the grease to flow down over the front of the planetary gears. If you inject grease through the lifter nut it only goes to the outside of the cam drum.

The Festo fitting can be plugged with a short 3 mm bolt.

So, the question now becomes: Will removing the piston (con rod) have any adverse effect on the top planetary gear alignment?

The front brass spacer should keep it in place?

Regards - J Tab

#5138

My Feedback: (2)

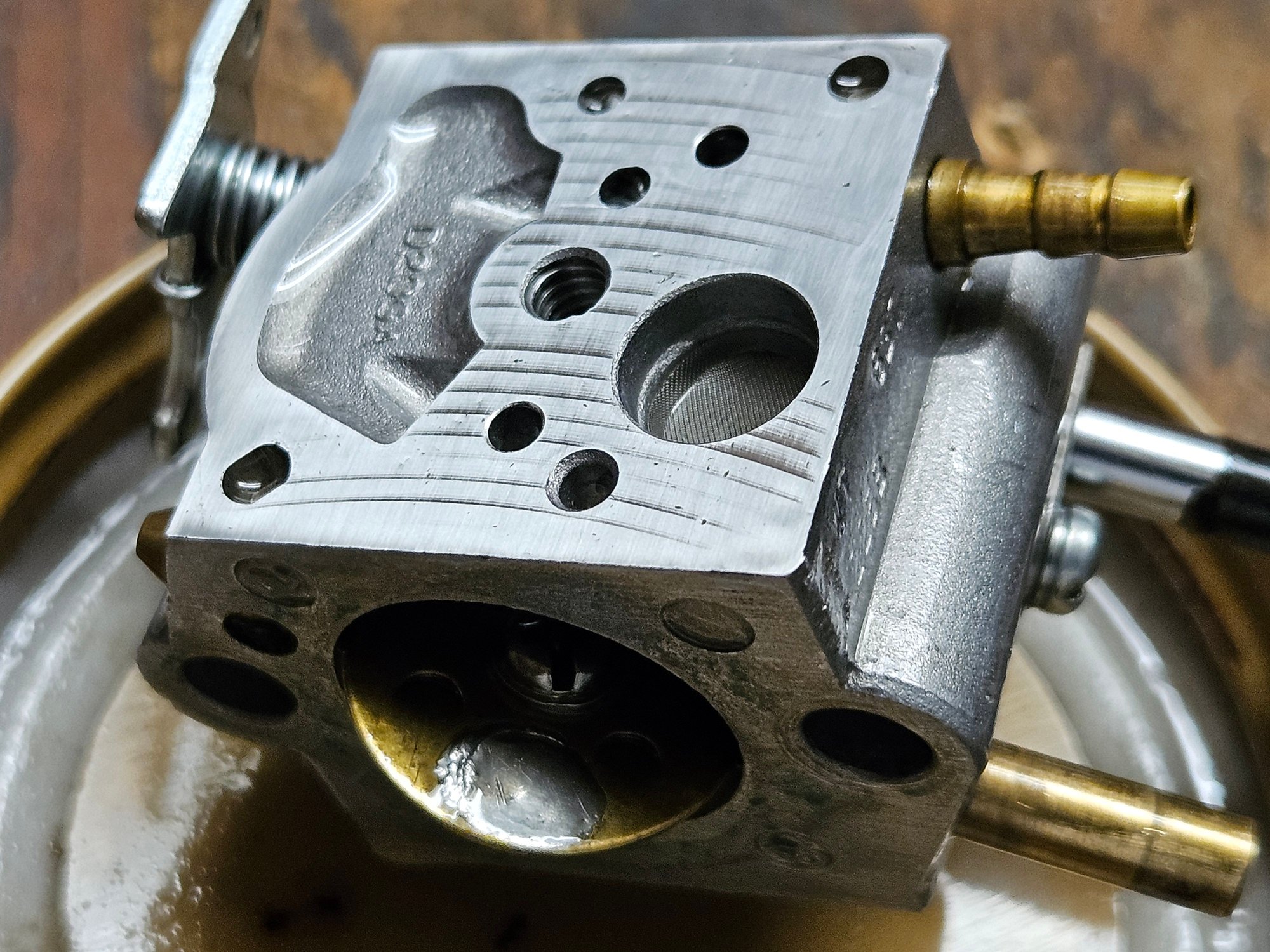

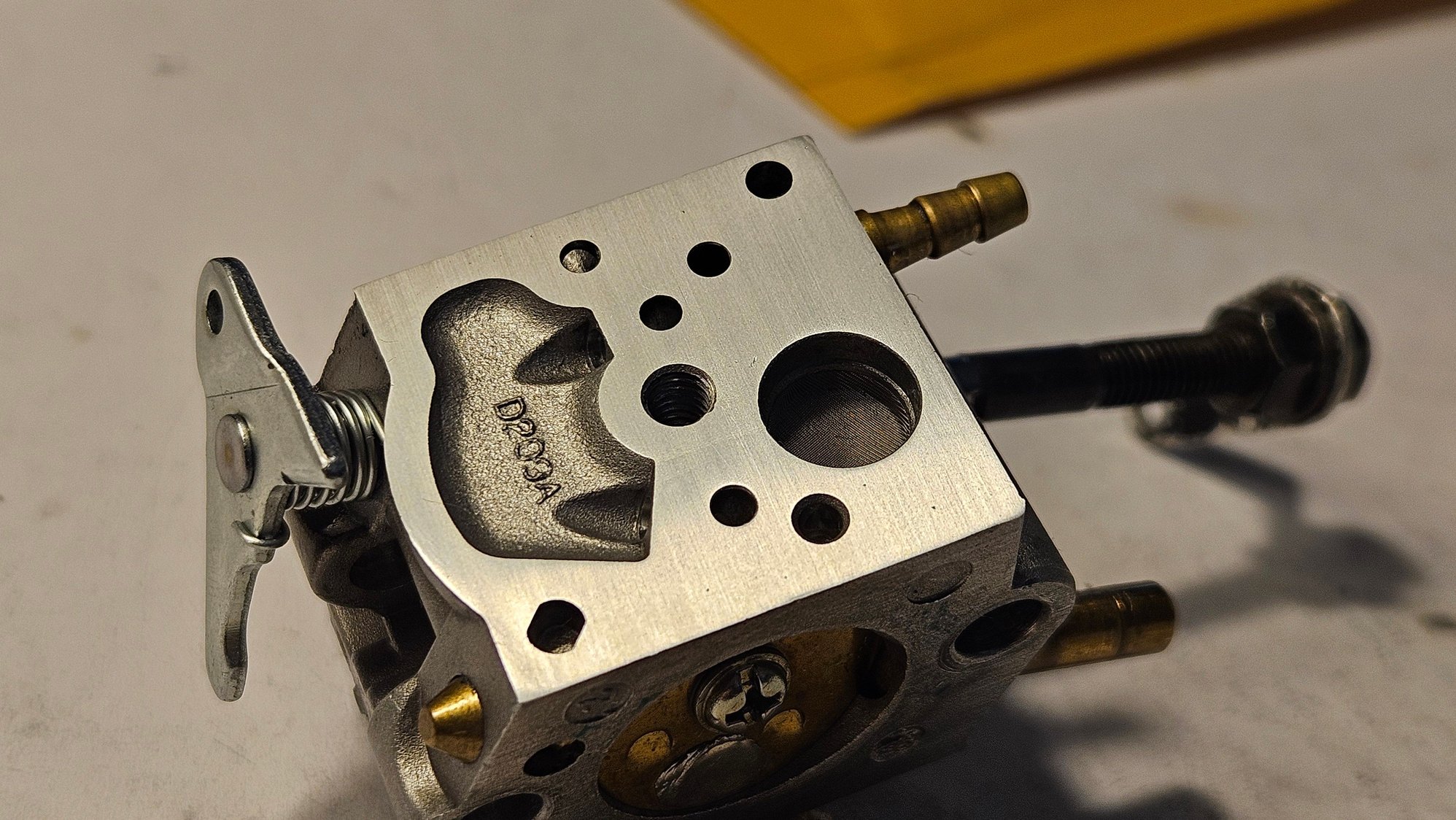

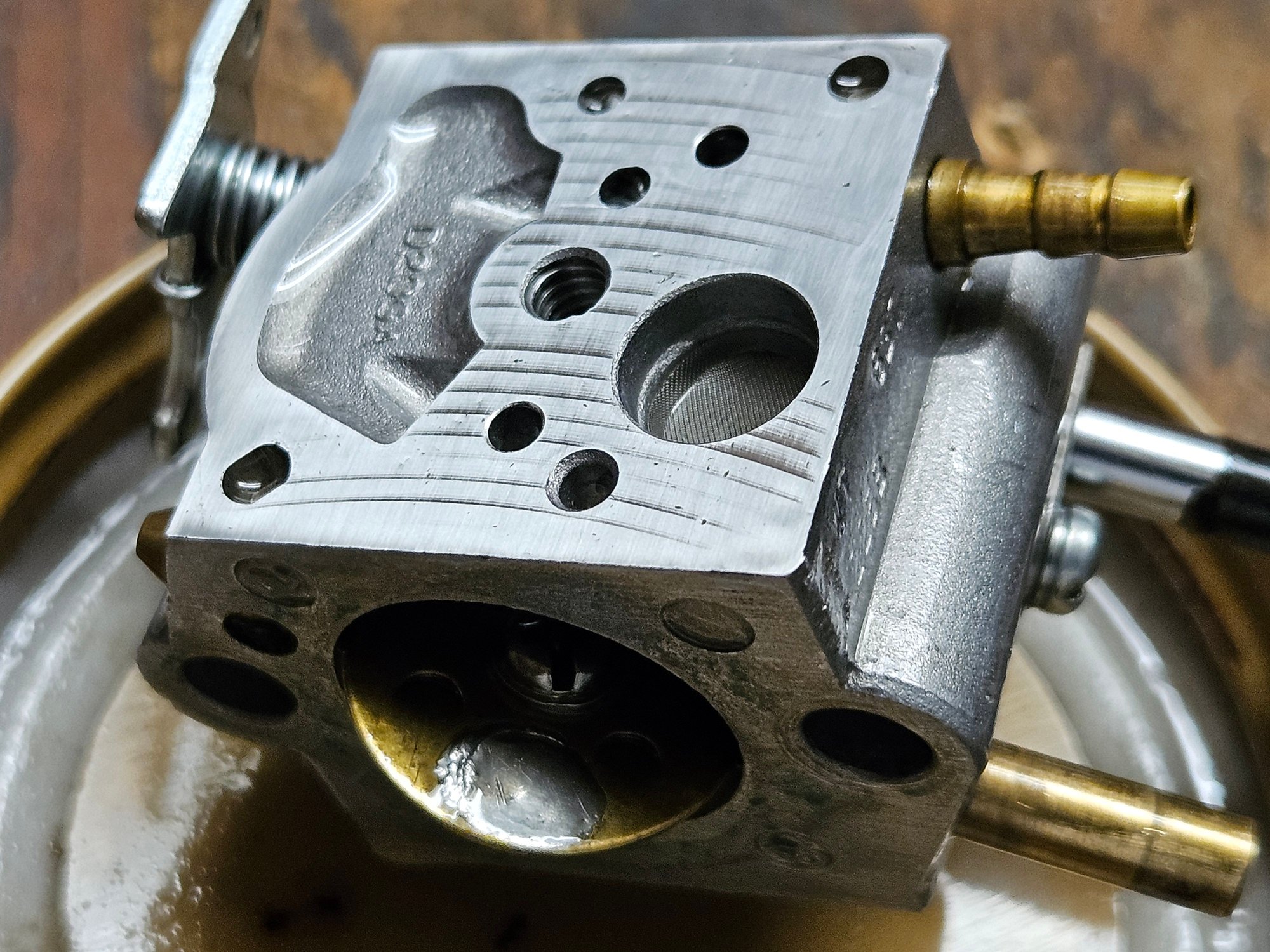

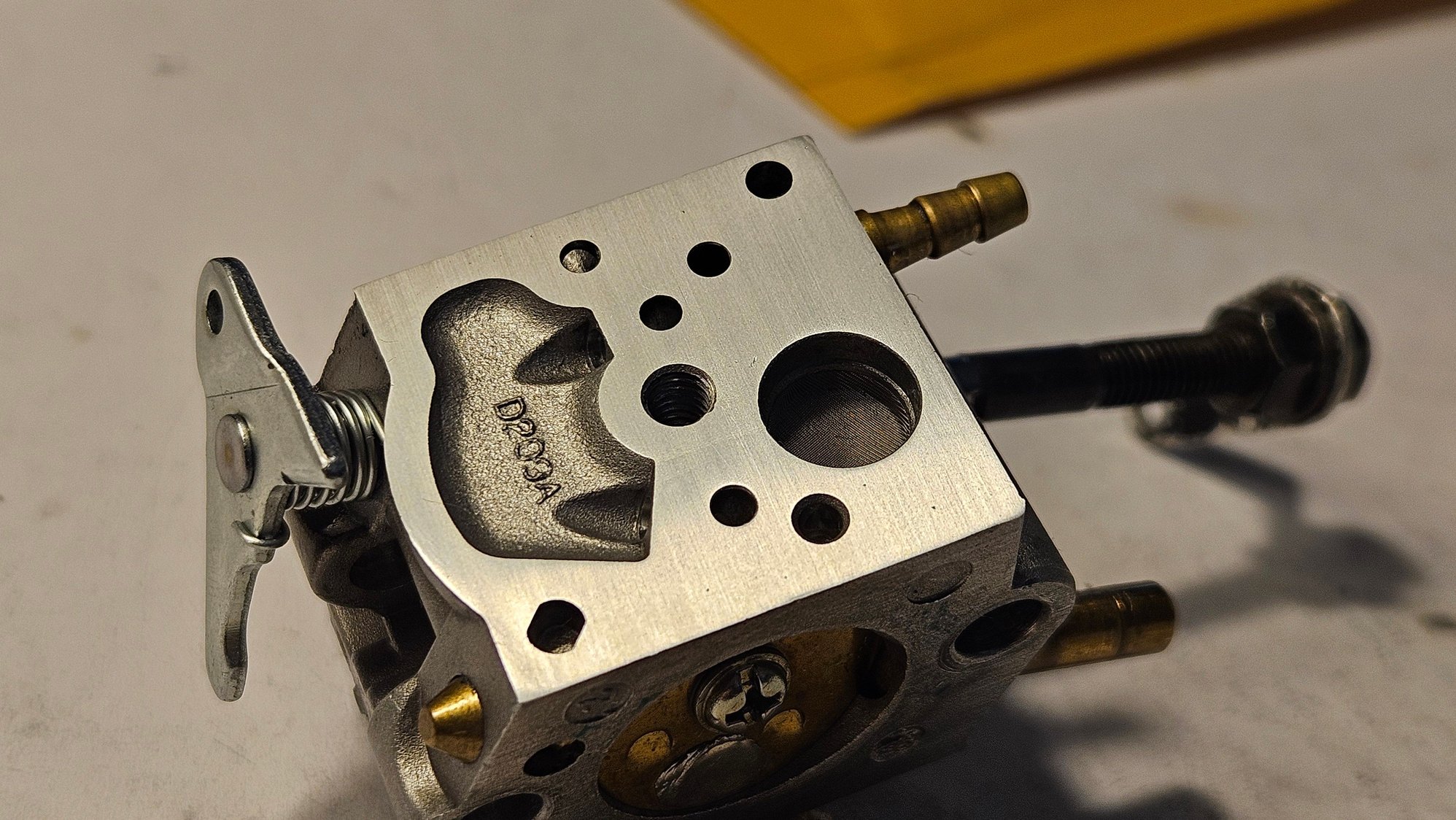

The carb on my 250 is the Wabro 225B, 837. I'm going to take a wild guess and say after 11 years it might be time for a little maintenance.

QUESTION - Is the correct gasket kit Walbro part # D10-WAT? Regards - J Tab

Edit: Confirmed from another source - D10-WAT is the correct gasket set.

QUESTION - Is the correct gasket kit Walbro part # D10-WAT? Regards - J Tab

Edit: Confirmed from another source - D10-WAT is the correct gasket set.

Last edited by Jaketab; 01-13-2024 at 03:23 PM.

#5139

My Feedback: (7)

Detlef,

Yes, I noticed that the piston is offset. I've already experimented with reinstalling it.

I'm thinking of omitting the piston for 3 reasons.

1. I use the electric pump.

2. The piston connecting rod is difficult to place over the cam gear.

3. Most importantly, in the future by simply removing the pump cylinder housing will give excellent access to refresh the grease, which would allow the grease to flow down over the front of the planetary gears. If you inject grease through the lifter nut it only goes to the outside of the cam drum.

The Festo fitting can be plugged with a short 3 mm bolt.

So, the question now becomes: Will removing the piston (con rod) have any adverse effect on the top planetary gear alignment?

The front brass spacer should keep it in place?

Regards - J Tab

Yes, I noticed that the piston is offset. I've already experimented with reinstalling it.

I'm thinking of omitting the piston for 3 reasons.

1. I use the electric pump.

2. The piston connecting rod is difficult to place over the cam gear.

3. Most importantly, in the future by simply removing the pump cylinder housing will give excellent access to refresh the grease, which would allow the grease to flow down over the front of the planetary gears. If you inject grease through the lifter nut it only goes to the outside of the cam drum.

The Festo fitting can be plugged with a short 3 mm bolt.

So, the question now becomes: Will removing the piston (con rod) have any adverse effect on the top planetary gear alignment?

The front brass spacer should keep it in place?

Regards - J Tab

I removed the awful black grease the factory loaded into my moki 300 earlier in this thread and replaced it with gear lube - like you have done. I really wanted to leave the piston out of the air pump since it no longer serves a function and plug that line, but I was worried about completely capping off the gearbox (on retrospection I'm not sure why). On the other hand I didn't want to leave it open for the oil to just run right out of when inverted. I chose to just put the piston back in.

I wonder which method Detlef chose. . . . . .

#5140

I will ask him when I see him :-)

When you have oil / liquid grease in the gearbox ( which I prefer by far) and use an electric fuel pump, there i s no need for the piston any more.

Simply drop it is no good idea, the grease will come out of the 3 mm hose, more than you might like.

There is a small venting hole at the backside of the pump cylinder, that serves as the ventilation each and any gearbox needs.

I turned a pice of PA-6 (a plastic material) to fit tight / press in the cylinder, that one seals the original vent bore, but carries a 1 mm bore leading to the 3 mm hose.

So I can lead the venting end to wherever I like, not polluting the engine´s front side.

In fact,not much is coming out of the hose, but the venting is still intact. You want no pressure in the gearbox when the engine is hot

Last edited by Detlef Kunkel; 02-10-2024 at 08:46 AM.

#5141

#5142

My Feedback: (2)

When I was refilling the gear housing with gear oil, I found it dissipating somewhere. It required refilling about twice per flying season. Having replaced the front bearing, repacked with blue factory grease, and removing the pump piston, I now have easy access to replenish the grease as needed. So far, in ground testing the motor without the pump piston, the grease has not seeped out of the Festo fitting or the weep hole.

On another note, I cleaned and installed a new pump membrane and diaphragm on the Walbro 225B carb. As someone else described it, the pump side face appeared that a "Cheese Grater" had done the milling. After fine sanding on a flat surface you can see the difference. Upon running the motor, it now has a much smoother mid-range and transition.

On another note, I cleaned and installed a new pump membrane and diaphragm on the Walbro 225B carb. As someone else described it, the pump side face appeared that a "Cheese Grater" had done the milling. After fine sanding on a flat surface you can see the difference. Upon running the motor, it now has a much smoother mid-range and transition.

#5144

My Feedback: (47)

Hello Guys,

I have a quick question and I looked through the thread and I apologize if I missed it. I am looking for a dimensional drawing for the Moki 180 so I can check fit into my Top RC T-28. I have searched the internet too and I am coming up short. If anybody has one for sale too, please reach out!

Thanks in advance, talk soon.

Jason

I have a quick question and I looked through the thread and I apologize if I missed it. I am looking for a dimensional drawing for the Moki 180 so I can check fit into my Top RC T-28. I have searched the internet too and I am coming up short. If anybody has one for sale too, please reach out!

Thanks in advance, talk soon.

Jason

#5145

My Feedback: (2)

Hello Guys,

I have a quick question and I looked through the thread and I apologize if I missed it. I am looking for a dimensional drawing for the Moki 180 so I can check fit into my Top RC T-28. I have searched the internet too and I am coming up short. If anybody has one for sale too, please reach out!

Thanks in advance, talk soon.

Jason

I have a quick question and I looked through the thread and I apologize if I missed it. I am looking for a dimensional drawing for the Moki 180 so I can check fit into my Top RC T-28. I have searched the internet too and I am coming up short. If anybody has one for sale too, please reach out!

Thanks in advance, talk soon.

Jason

Airworld.de is the worldwide distributor of Moki radial engines. You should find all the dimension drawings there.

Last edited by Jaketab; 02-12-2024 at 09:02 PM.

#5146

My Feedback: (47)

Contact Brendon at Just Plane Crazy. He just posted newly completed video of at TRC T-28 with a UMS180. His Face Book page and You Tube channel are: Just Plane Crazy.

Airworld.de is the worldwide distributor of Moki radial engines. You should find all the dimension drawings there.

Airworld.de is the worldwide distributor of Moki radial engines. You should find all the dimension drawings there.

Thank you for the diagram, that is certainly helpful and I can import that and create a Dummy Moki 180 that I can use for mockup. I only saw the older measurements that showed the Moki 150, so I do appreciate it.

I wish Airworld would ship to the United States!

Last edited by JRSmith; 02-13-2024 at 09:28 AM.

#5148

My Feedback: (47)

Still on the hunt for a Moki 180. However, in the meantime, I have an opportunity to purchase a older Moki 150 (from 2011), Has the Rainbow-Tronic ignition and APS Fuel Pump. It has about four hours of run time, all on the bench. Grease has been replaced and it looks like it runs good.

Since the 150 has been discontinued and Vogelsang no longer imports the brand in the US, I have a couple questions.

1. Is there a certified US service center for Moki Radials?

2. Is parts support for the 150 available?

3. Does anybody know why Airworld will not ship to the US any longer?

The only reason to ask the Airworld question, if they are the worldwide distributor and they DON'T ship to the US, then I would believe US parts support would be problematic?

Thanks in advance and I appreciate the replies!

Jason

Since the 150 has been discontinued and Vogelsang no longer imports the brand in the US, I have a couple questions.

1. Is there a certified US service center for Moki Radials?

2. Is parts support for the 150 available?

3. Does anybody know why Airworld will not ship to the US any longer?

The only reason to ask the Airworld question, if they are the worldwide distributor and they DON'T ship to the US, then I would believe US parts support would be problematic?

Thanks in advance and I appreciate the replies!

Jason

#5149

My Feedback: (2)

Still on the hunt for a Moki 180. However, in the meantime, I have an opportunity to purchase a older Moki 150 (from 2011), Has the Rainbow-Tronic ignition and APS Fuel Pump. It has about four hours of run time, all on the bench. Grease has been replaced and it looks like it runs good.

Since the 150 has been discontinued and Vogelsang no longer imports the brand in the US, I have a couple questions.

1. Is there a certified US service center for Moki Radials?

2. Is parts support for the 150 available?

3. Does anybody know why Airworld will not ship to the US any longer?

The only reason to ask the Airworld question, if they are the worldwide distributor and they DON'T ship to the US, then I would believe US parts support would be problematic?

Thanks in advance and I appreciate the replies!

Jason

Since the 150 has been discontinued and Vogelsang no longer imports the brand in the US, I have a couple questions.

1. Is there a certified US service center for Moki Radials?

2. Is parts support for the 150 available?

3. Does anybody know why Airworld will not ship to the US any longer?

The only reason to ask the Airworld question, if they are the worldwide distributor and they DON'T ship to the US, then I would believe US parts support would be problematic?

Thanks in advance and I appreciate the replies!

Jason

Have you contacted a CARF representative to see if they could fill your order for a Moki180?

Last June/2023 I ordered Moki parts directly from Airworld and also directly from Jim Baker who is the Moki USA factory rep for CARF.

Home | Moki Radial Service (mokiradialserviceusa.com)

Regards - J Tab

#5150

My Feedback: (47)

Jason,

Have you contacted a CARF representative to see if they could fill your order for a Moki180?

Last June/2023 I ordered Moki parts directly from Airworld and also directly from Jim Baker who is the Moki USA factory rep for CARF.

Home | Moki Radial Service (mokiradialserviceusa.com)

Regards - J Tab

Have you contacted a CARF representative to see if they could fill your order for a Moki180?

Last June/2023 I ordered Moki parts directly from Airworld and also directly from Jim Baker who is the Moki USA factory rep for CARF.

Home | Moki Radial Service (mokiradialserviceusa.com)

Regards - J Tab

That is awesome that you were able to order from Airworld. I tried and USA is no longer a shipping option. I also tried to order from Heilemann Sternmotoren last week and the same thing, they do not ship to the US any longer. I was told by by them, it is due to product liability regulations in the USA. Seidel Props, the same thing!

Lots of great German model companies no longer shipping to the US! Anyway, I guess its a sign of the times. I will check with Jim Baker and see if he has replacement parts for the Moki 150 before purchasing this used unit. Thank you.

Last edited by JRSmith; 02-23-2024 at 06:45 AM.