Alm Meca Turbines

#1

Hey guys, how’s it going? Just received my alm meca ALM-Meca Turbines A-180 and supper excited to announce that I am the new (and first) usa support. This past season I extensively have tested this turbine and it has done me nothing but good, quick throttle response and no uat required. If you want to see more posts about alm meca please join my group alm-meca turbines usa here on Facebook where I will be doing more posts. Thanks everyone!

Here are some of the few highlights I for got to mention about why the alm meca brand is a great choice for your next turbine selection:

1.) Comes with life time warranty

2.) Service intervals are 50hours or 2 years after purchase date(which ever one comes first)

3.) Runs on 2s lipos 7.4v

4.) Comes in any color combination you wish

5.) All turbines are made to order custom so custom made wire harness to fit your needs

6.) No uat required with proper fuel clunc

7.) Pump ecu all in one

8.) Alm-meca brand turbine oil

9.) comes in 180 and 210 size with many other sizes in development

10.) comes with beautifully cnc’d bracket

11.) currently serviced in France with very fast turn around time with plans of opening another service center in USA

Once again if you have any question please send me a private message or send me an email at [email protected] . Thanks for your time!

Here are some of the few highlights I for got to mention about why the alm meca brand is a great choice for your next turbine selection:

1.) Comes with life time warranty

2.) Service intervals are 50hours or 2 years after purchase date(which ever one comes first)

3.) Runs on 2s lipos 7.4v

4.) Comes in any color combination you wish

5.) All turbines are made to order custom so custom made wire harness to fit your needs

6.) No uat required with proper fuel clunc

7.) Pump ecu all in one

8.) Alm-meca brand turbine oil

9.) comes in 180 and 210 size with many other sizes in development

10.) comes with beautifully cnc’d bracket

11.) currently serviced in France with very fast turn around time with plans of opening another service center in USA

Once again if you have any question please send me a private message or send me an email at [email protected] . Thanks for your time!

#2

My Feedback: (2)

Few questions since I am not on FB.

How long has Alm Meca Turbines been around?

How do they operate at higher elevations 5000+ft

What is Alm-meca brand turbine oil? Can't use anything else?

Website just shows the usual sales pitch, I don't see any specs or prices.

What makes Alm-meca turbines different from what's currently available in the market?

Let's say Alm-meca turbinesgoes out of business, am I left with a turbine anchor? custom parts and service?

How long has Alm Meca Turbines been around?

How do they operate at higher elevations 5000+ft

What is Alm-meca brand turbine oil? Can't use anything else?

Website just shows the usual sales pitch, I don't see any specs or prices.

What makes Alm-meca turbines different from what's currently available in the market?

Let's say Alm-meca turbinesgoes out of business, am I left with a turbine anchor? custom parts and service?

#4

My Feedback: (2)

Above, plus:

-Why a custom wiring harness? What’s the advantage there when the “built to order” tradeoff is delayed delivery to the customer?

-The exhaust cone resembles older designs that the brands with which I am familiar have moved away from. Is there an advantage to your design?

-Why a combined ECU/Fuel Pump? Does that not result in an issue with one requiring removal and service of both?

-Why no UAT with a “proper” clunk, and what exactly is a “proper” clunk? Is there a new TURBINE (vs clunk) technology involved that all other manufacturers have missed?

This is a fairly sophisticated audience you’re selling to, so I urge that you provide a lot more information than provided thus far ;-)

-Why a custom wiring harness? What’s the advantage there when the “built to order” tradeoff is delayed delivery to the customer?

-The exhaust cone resembles older designs that the brands with which I am familiar have moved away from. Is there an advantage to your design?

-Why a combined ECU/Fuel Pump? Does that not result in an issue with one requiring removal and service of both?

-Why no UAT with a “proper” clunk, and what exactly is a “proper” clunk? Is there a new TURBINE (vs clunk) technology involved that all other manufacturers have missed?

This is a fairly sophisticated audience you’re selling to, so I urge that you provide a lot more information than provided thus far ;-)

Last edited by highhorse; 11-13-2022 at 05:03 PM.

#5

Few questions since I am not on FB.

How long has Alm Meca Turbines been around?

How do they operate at higher elevations 5000+ft

What is Alm-meca brand turbine oil? Can't use anything else?

Website just shows the usual sales pitch, I don't see any specs or prices.

What makes Alm-meca turbines different from what's currently available in the market?

Let's say Alm-meca turbinesgoes out of business, am I left with a turbine anchor? custom parts and service?

How long has Alm Meca Turbines been around?

How do they operate at higher elevations 5000+ft

What is Alm-meca brand turbine oil? Can't use anything else?

Website just shows the usual sales pitch, I don't see any specs or prices.

What makes Alm-meca turbines different from what's currently available in the market?

Let's say Alm-meca turbinesgoes out of business, am I left with a turbine anchor? custom parts and service?

Alm meca turbines have been around for a few years making turbine model engines but they have been around for a lot longer doing custom machining parts. Alm meca has its own branded oil but if you wish to use other brand oils that not an issues, it doesn’t void warrants like other brands. Currently alm meca is in the process of making a more in-depth website at least for the turbine side, it should be out in the next couple of weeks. Current prices for the A-180 is €2750+vat and the A-210 is €3150+vat. As for alm meca hanging around, I think they have some very cool features like no other brand and it’s nicely done for example you will find beautiful machining for the turbine bracket and such. It’s done very well and plan to stay as this isn’t the sole income they rely on so they have more capital to work with. For how the turbine working at higher elevations I can not say as I and believe they haven’t test at such high elevations, but will ask. Highest elevation I flew at is about 1000ft and I felt absolutely no effects and it was about 85f out. For what makes it different or sets it apart; the cool custom colors to match your airplane I think is very cool and no other brand does, 50hour service intervals no one does, the beautiful cnc machined bracket is done like no other brands, the custom wiring harness to fit your needs is also only done by one; Alm-meca. Thank you!

#6

Above, plus:

-Why a custom wiring harness? What’s the advantage there when the “built to order” tradeoff is delayed delivery to the customer?

-The exhaust cone resembles older designs that the brands with which I am familiar have moved away from. Is there an advantage to your design?

-Why a combined ECU/Fuel Pump? Does that not result in an issue with one requiring removal and service of both?

-Why no UAT with a “proper” clunk, and what exactly is a “proper” clunk? Is there a new TURBINE (vs clunk) technology involved that all other manufacturers have missed?

This is a fairly sophisticated audience you’re selling to, so I urge that you provide a lot more information than provided thus far ;-)

-Why a custom wiring harness? What’s the advantage there when the “built to order” tradeoff is delayed delivery to the customer?

-The exhaust cone resembles older designs that the brands with which I am familiar have moved away from. Is there an advantage to your design?

-Why a combined ECU/Fuel Pump? Does that not result in an issue with one requiring removal and service of both?

-Why no UAT with a “proper” clunk, and what exactly is a “proper” clunk? Is there a new TURBINE (vs clunk) technology involved that all other manufacturers have missed?

This is a fairly sophisticated audience you’re selling to, so I urge that you provide a lot more information than provided thus far ;-)

The custom wiring harness is just to make the customers life easier, so it makes it easier for install. As you know all the other brands give you one size length wire and from time to time at least for me it’s so long I don’t know what to do or it’s so short that I have to go buy other wires and that’s extra money having to spend. This is just a kill two birds with one stone situation. The reason for build to order is so each turbine could be tested precisely and made sure that ever run as they should and customer doesn’t end up with any issues, worst thing is getting a new turbine and having issues right from the get go because some little thing wasn't don’t correctly and causes you headaches. Customer as of now will not experience any delays because of the built to order, will get it, maybe even quicker then some of the other brands out depending on where you are in the world. Reason for proper clunk is a get clunk is required to work properly, I have tested this with a normal brass clunk and then switching over to felt clunk, I did all the flips and roll and anything I could throw at it and had no flame outs with either but with the brass it would sputter a bit and I did not like that.

The following users liked this post:

Desertlakesflying (11-14-2022)

#8

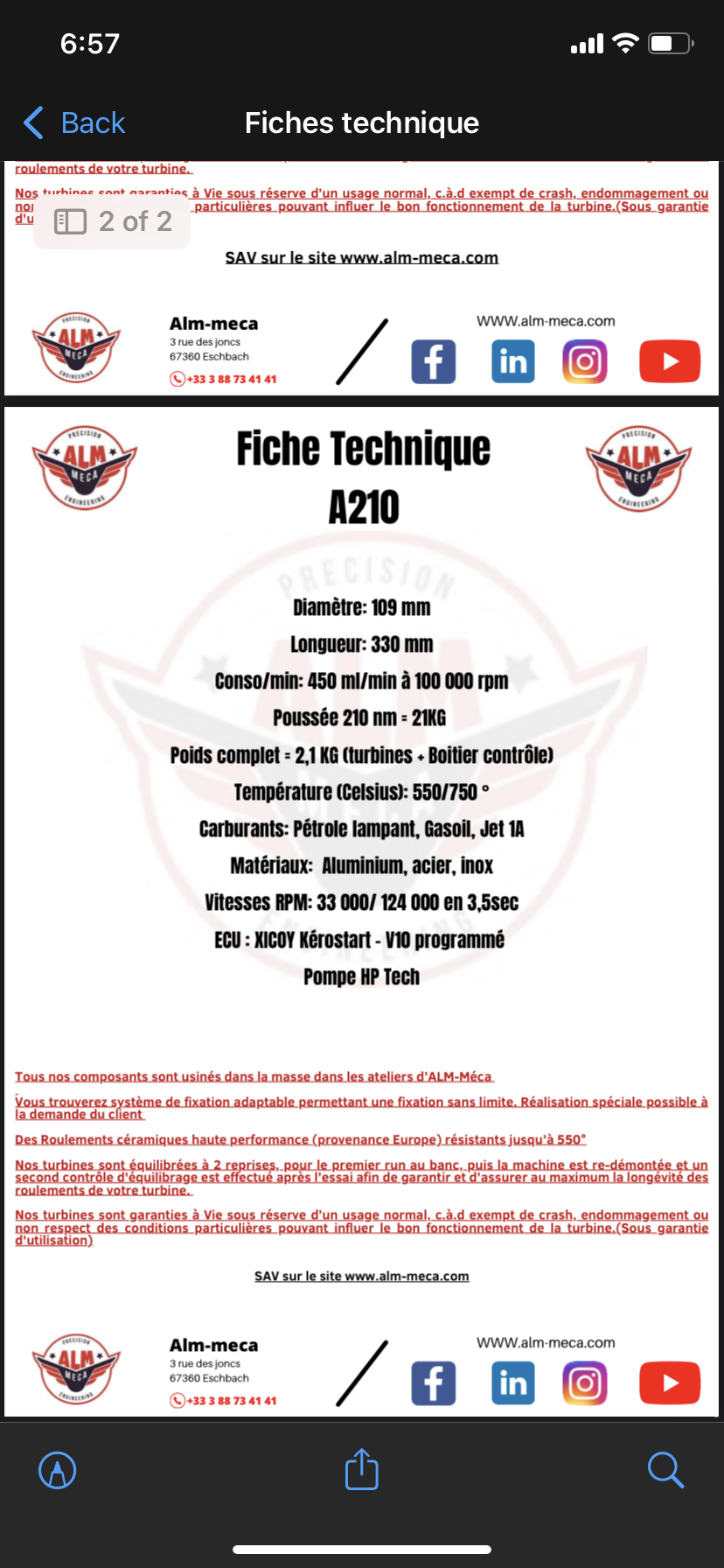

Here is a France to English translation to the file I attached

A-210Diameter: 109mm

Length: 330mm

Consumption/min: 450 ml/min at 100,000 rpm

Thrust 210 nm = 21KG

Complete weight = 2.1 KG (turbines + control box)

Temperature (Celsius): 550/750°

Fuels: Kerosene, Diesel, Jet 1A

Materials: Aluminum, steel, stainless steel

RPM Speeds: 33,000/ 124,000 in 3.5sec

ECU: XICOY Kérostart – V10 programmed

HP Tech pumpSome words about our difference :

A-180Diameter: 109mm

Length: 330mm

Consumption/min: 370 ml/min at 100,000 rpm

Thrust 180 nm = 18KG

Complete weight = 2KG turbines + control box

Temperature (Celsius): 550/750°

Fuels: Kerosene, Diesel, Jet 1A

Materials: Aluminum, steel, stainless steel

RPM Speeds: 33,000/ 126,000 in 3.5sec

ECU: XICOY Kérostart – V10 programmed

HP Tech pump

Some words about our difference :

A-210Diameter: 109mm

Length: 330mm

Consumption/min: 450 ml/min at 100,000 rpm

Thrust 210 nm = 21KG

Complete weight = 2.1 KG (turbines + control box)

Temperature (Celsius): 550/750°

Fuels: Kerosene, Diesel, Jet 1A

Materials: Aluminum, steel, stainless steel

RPM Speeds: 33,000/ 124,000 in 3.5sec

ECU: XICOY Kérostart – V10 programmed

HP Tech pumpSome words about our difference :

- All components are full machined from full material.

- Tunnel is in steel (no aluminum)

- Combustion chamber is in Inconel 0.5mm complete welded with 12 injectors

- Ceramic ball bearing from GRW (Germany) with special material can be used up to 550°c

- Less of consumption

- ECU box which is now 80x80x45mm and will be with our new ECU 68x68x42 with option in Aluminum

- Color could be customized

- Life warranty

A-180Diameter: 109mm

Length: 330mm

Consumption/min: 370 ml/min at 100,000 rpm

Thrust 180 nm = 18KG

Complete weight = 2KG turbines + control box

Temperature (Celsius): 550/750°

Fuels: Kerosene, Diesel, Jet 1A

Materials: Aluminum, steel, stainless steel

RPM Speeds: 33,000/ 126,000 in 3.5sec

ECU: XICOY Kérostart – V10 programmed

HP Tech pump

Some words about our difference :

- All components are full machined from full material.

- Tunnel is in steel (no aluminum)

- Combustion chamber is in Inconel 0.5mm complete welded with 12 injectors

- Ceramic ball bearing from GRW (Germany) with special material can be used up to 550°c

- Less of consumption

- ECU box which is now 80x80x45mm and will be with our new ECU 68x68x42 with option in Aluminum

- Color could be customized

- Life warranty

#9

My Feedback: (2)

Peter, I also tried to attain more information via the web site. Only vague generalities and no specifics available, resembling vaporware. I wish no failure on any manufacturer, but this seems a shaky and premature rollout which does not make a favorable first impression. I sincerely hope that the manufacturer gives you better backing than this as you try to make a go of supporting the community.

The following users liked this post:

Springbok Flyer (11-13-2022)

#10

Sorry I don’t have that info right now but I will ask and see what they say. Sorry about the inconvenience.

#11

My Feedback: (2)

The custom wiring harness is just to make the customers life easier, so it makes it easier for install. As you know all the other brands give you one size length wire and from time to time at least for me it’s so long I don’t know what to do or it’s so short that I have to go buy other wires and that’s extra money having to spend. This is just a kill two birds with one stone situation. The reason for build to order is so each turbine could be tested precisely and made sure that ever run as they should and customer doesn’t end up with any issues, worst thing is getting a new turbine and having issues right from the get go because some little thing wasn't don’t correctly and causes you headaches. Customer as of now will not experience any delays because of the built to order, will get it, maybe even quicker then some of the other brands out depending on where you are in the world. Reason for proper clunk is a get clunk is required to work properly, I have tested this with a normal brass clunk and then switching over to felt clunk, I did all the flips and roll and anything I could throw at it and had no flame outs with either but with the brass it would sputter a bit and I did not like that.

Are you stating or even implying that other manufacturer’s turbines are not tested precisely, have more issues or are in some way more trouble prone for not having been “built to order”? I for one do not see the logic there at all.

Felt clunks have been around for many years, as have some users’ success without UATs, so will ask again if there’s a new TURBINE technology utilized which is specific to your manufacturer and which leads you to claim no UAT required as a selling point? If not, then why mention it at all?

I wish you the best sir, but so far your posts and attempted explanations here have not inspired confidence.

Last edited by highhorse; 11-13-2022 at 05:49 PM.

The following users liked this post:

Springbok Flyer (11-13-2022)

#12

Peter, I also tried to attain more information via the web site. Only vague generalities and no specifics available, resembling vaporware. I wish no failure on any manufacturer, but this seems a shaky and premature rollout which does not make a favorable first impression. I sincerely hope that the manufacturer gives you better backing than this as you try to make a go of supporting the community.

#13

Well I for one have never had issues with wiring length, either too short or so long I “don’t know what to do”.

Are you stating or even implying that other manufacturer’s turbines are not tested precisely, have more issues or are in some way more trouble prone for not having been “built to order”? I for one do not see the logic there at all.

Felt clunks have been around for many years, as have some users’ success without UATs, so will ask again if there’s a new TURBINE technology utilized which is specific to your manufacturer and which leads you to claim no UAT required as a selling point? If not, then why mention it at all?

Are you stating or even implying that other manufacturer’s turbines are not tested precisely, have more issues or are in some way more trouble prone for not having been “built to order”? I for one do not see the logic there at all.

Felt clunks have been around for many years, as have some users’ success without UATs, so will ask again if there’s a new TURBINE technology utilized which is specific to your manufacturer and which leads you to claim no UAT required as a selling point? If not, then why mention it at all?

About the wire situation I am happy that you have never experienced that, me personally and I know many around me have experienced this issue when building a new model and it’s a real pain in the butt especially when you are racing the clock so you could get to the field because good weather or a event of some sort.

The following 2 users liked this post by F900:

Canadian Man (11-13-2022),

Desertlakesflying (11-14-2022)

#15

My Feedback: (2)

OK, so….I will be very straight forward here without seeming abrasive.

You have failed -twice now- to substantiate the claimed “highlight” in your original post of no UAT required, other than referring to use of felt clunks which have been around for many years and available for use on any turbine.

Your engines are, objectively speaking, significantly heavier than competitors’ units, are significantly more expensive, have unspecified fuel flows at max power, but offset this drawbacks with custom wire lengths and color?

Even the claimed 50 hour service interval seems completely negated due to the “…or two years, whichever comes first” stipulation, which would surely be the limiting factor for the vast majority of users.

If I am mistaken or missing something then please do correct me.

You have failed -twice now- to substantiate the claimed “highlight” in your original post of no UAT required, other than referring to use of felt clunks which have been around for many years and available for use on any turbine.

Your engines are, objectively speaking, significantly heavier than competitors’ units, are significantly more expensive, have unspecified fuel flows at max power, but offset this drawbacks with custom wire lengths and color?

Even the claimed 50 hour service interval seems completely negated due to the “…or two years, whichever comes first” stipulation, which would surely be the limiting factor for the vast majority of users.

If I am mistaken or missing something then please do correct me.

#16

My Feedback: (2)

Where to start......

To be honest, JetJoe looked a better product that this.

I would anticipate that the market uptake on this will be approaching .......... zero.

Paul

- The 3D printed front cover and starter motor housing looks so........ home made

- The 3D printed FOD screen has huge blockage - I'd be surprised if the motor would be happy running behind that

- All-in-one pump and ECU is nothing more than a 3D printed box

- The engine technology looks so 1990's - cone exhaust, external EGT probe and the 2 valves mounted in the ECU/ pump box and not in the motor

- ECU data terminal is the same as I had from engines 20 years ago

- Engine weight at least 1lb heavier than modern, known brand motors

- 500Euro more expensive than modern, known brand motors

- If you think the motor color is what will sell this motor, then you seriously don't understand this segment of the hobby

To be honest, JetJoe looked a better product that this.

I would anticipate that the market uptake on this will be approaching .......... zero.

Paul

#17

Where to start......

To be honest, JetJoe looked a better product that this.

I would anticipate that the market uptake on this will be approaching .......... zero.

Paul

- The 3D printed front cover and starter motor housing looks so........ home made

- The 3D printed FOD screen has huge blockage - I'd be surprised if the motor would be happy running behind that

- All-in-one pump and ECU is nothing more than a 3D printed box

- The engine technology looks so 1990's - cone exhaust, external EGT probe and the 2 valves mounted in the ECU/ pump box and not in the motor

- ECU data terminal is the same as I had from engines 20 years ago

- Engine weight at least 1lb heavier than modern, known brand motors

- 500Euro more expensive than modern, known brand motors

- If you think the motor color is what will sell this motor, then you seriously don't understand this segment of the hobby

To be honest, JetJoe looked a better product that this.

I would anticipate that the market uptake on this will be approaching .......... zero.

Paul

#18

My Feedback: (2)

Who's signing up lol?

Peter.... reliability and quality is yet to be determined with this turbine, if Alm Meca are really serious about selling these turbines in the US, having some loaners sent out to people who can review and test them to report back goes along way, asking people spend $3000+ on a new turbine, untested in the US is asking for zero sales or very little.

Also your stated " 50hour service intervals no one does"

That's incorrect Behotec and BF-Turbines engines have 50hr intervals before service. I'm know there are others.

Peter.... reliability and quality is yet to be determined with this turbine, if Alm Meca are really serious about selling these turbines in the US, having some loaners sent out to people who can review and test them to report back goes along way, asking people spend $3000+ on a new turbine, untested in the US is asking for zero sales or very little.

Also your stated " 50hour service intervals no one does"

That's incorrect Behotec and BF-Turbines engines have 50hr intervals before service. I'm know there are others.

#19

Who's signing up lol?

Peter.... reliability and quality is yet to be determined with this turbine, if Alm Meca are really serious about selling these turbines in the US, having some loaners sent out to people who can review and test them to report back goes along way, asking people spend $3000+ on a new turbine, untested in the US is asking for zero sales or very little.

Also your stated " 50hour service intervals no one does"

That's incorrect Behotec and BF-Turbines engines have 50hr intervals before service. I'm know there are others.

Peter.... reliability and quality is yet to be determined with this turbine, if Alm Meca are really serious about selling these turbines in the US, having some loaners sent out to people who can review and test them to report back goes along way, asking people spend $3000+ on a new turbine, untested in the US is asking for zero sales or very little.

Also your stated " 50hour service intervals no one does"

That's incorrect Behotec and BF-Turbines engines have 50hr intervals before service. I'm know there are others.

I was unaware that behotecs have 50hr service cycles. I do know that Rc jet international did a write up about the turbine and they did some tests in the June/July publishing of this year.

#20

My Feedback: (22)

Lol most of my engines are more than 2 years old before I ever get them into a jet. It's one thing to run out of warranty because I'm lazy and don't get it into a jet but if I had to send an engine in that I've never run for service just to keep the warranty that's more than enough to keep me from buying it.

just my 2 cents.

just my 2 cents.

#23

My Feedback: (19)

Lol most of my engines are more than 2 years old before I ever get them into a jet. It's one thing to run out of warranty because I'm lazy and don't get it into a jet but if I had to send an engine in that I've never run for service just to keep the warranty that's more than enough to keep me from buying it.

just my 2 cents.

just my 2 cents.

#24

My Feedback: (53)

It also seem like an old design using the older Xicoy ECU and GSU, custom wiring doesn’t really work for me either….and 3D printing for an over 3k euro wow….

The no UAT y’a right felt clunk and very little to nothing on the web site, but still he’s posting everywhere….I don’t no, but call me Thomas…..

I wish him well…but definitely not for me.

The following users liked this post:

T22 Warrior (11-15-2022)

#25

My Feedback: (23)

I see lots od opinionated “facts” from the OP on why these are great, but nothing that can substantiated outside of his personal opinion on the product.

they look nice, but outside of that, you better bring something industry leading to the table in this part of the hobby to get people to give it a look.

they look nice, but outside of that, you better bring something industry leading to the table in this part of the hobby to get people to give it a look.