Skygate/CARF Viperjet

#701

Hi, I also fly ate 600 mt above sea level. My landing flap is about 65º-70º and I use about 5 mm crow with elevator mix (about 2 mm up elevator) only for landing flap. I have a Jet Central Cheetah 160. For landing, on upwind I lower the gear, when it is down I go to take off flap ,and once in downwind go to landing flaps between 1/4 and half throttle depending on wind. On final I keep the throttle at about 1/4 managing altitude with throttle so that it touches down a little past me. When I know I have reached the runway I go to Idle, usually at about 2 mt altitude. Some time we have a lot of wind and to bring it in throttle on final has to be more, it slows almost to a crawl with no bad habits.

Regards

Eduardo

Regards

Eduardo

The following users liked this post:

DenisFerrari (12-23-2021)

#702

If you have 2mm UP mixed with flap you are running nose heavy.

The Viper’s huge tail hides this situation well, it’s why people have been flying this aeroplane nose heavy since it was designed.

Dave

The Viper’s huge tail hides this situation well, it’s why people have been flying this aeroplane nose heavy since it was designed.

Dave

The following users liked this post:

DenisFerrari (02-01-2022)

#704

My Feedback: (30)

I have 1/4 scale pilot from warbirdpilots.com The pilot is 15" tall and fits just fine in my Viper.

https://www.warbirdpilots.com/Search...ilot-Red-White

The following 2 users liked this post by Asif:

DenisFerrari (03-25-2022),

Havilland (08-23-2024)

#705

My Feedback: (1)

I have 1/4 scale pilot from warbirdpilots.com The pilot is 15" tall and fits just fine in my Viper.

https://www.warbirdpilots.com/Search...ilot-Red-White

https://www.warbirdpilots.com/Search...ilot-Red-White

BR. Hans

The following users liked this post:

Havilland (08-23-2024)

#706

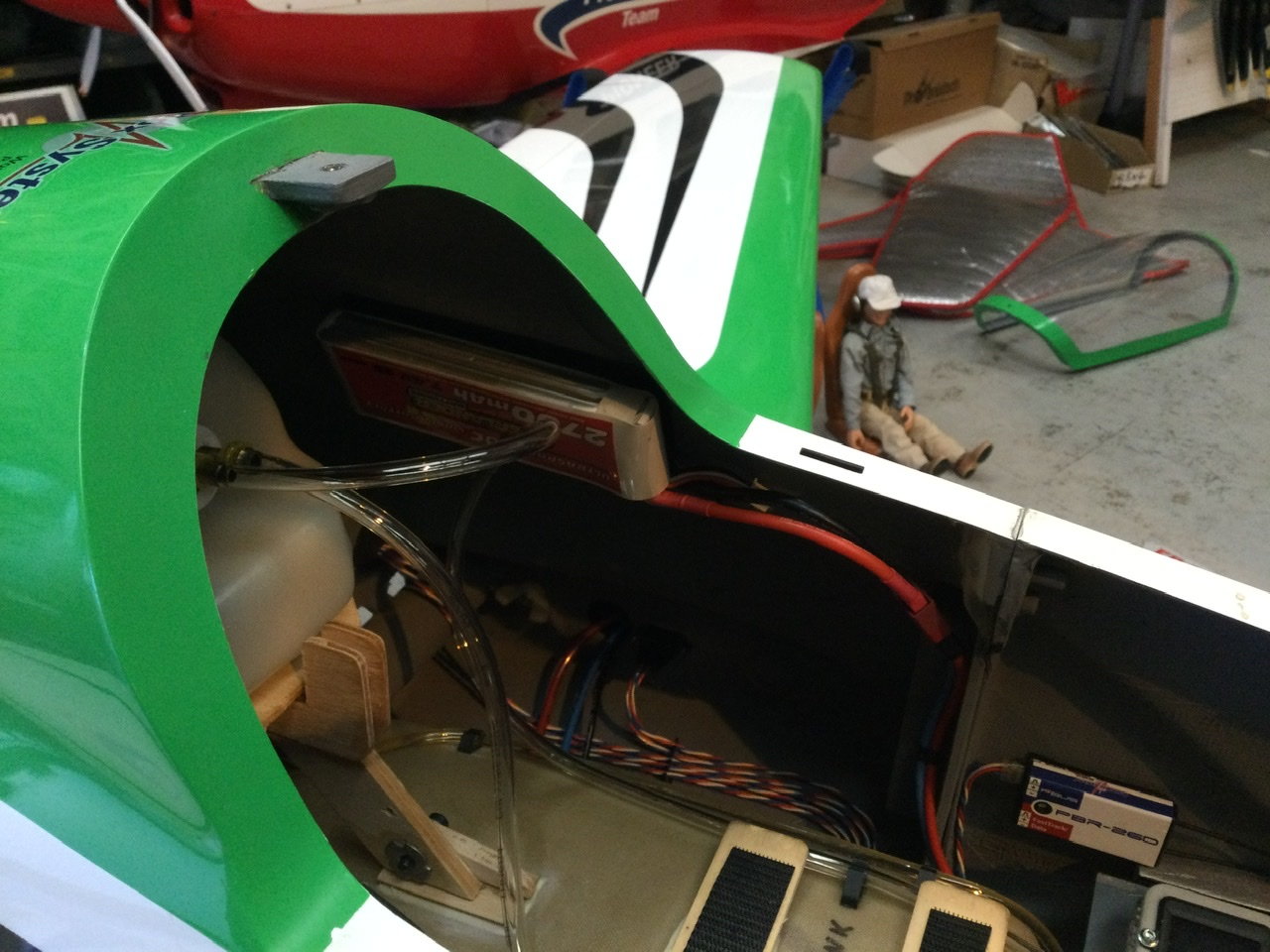

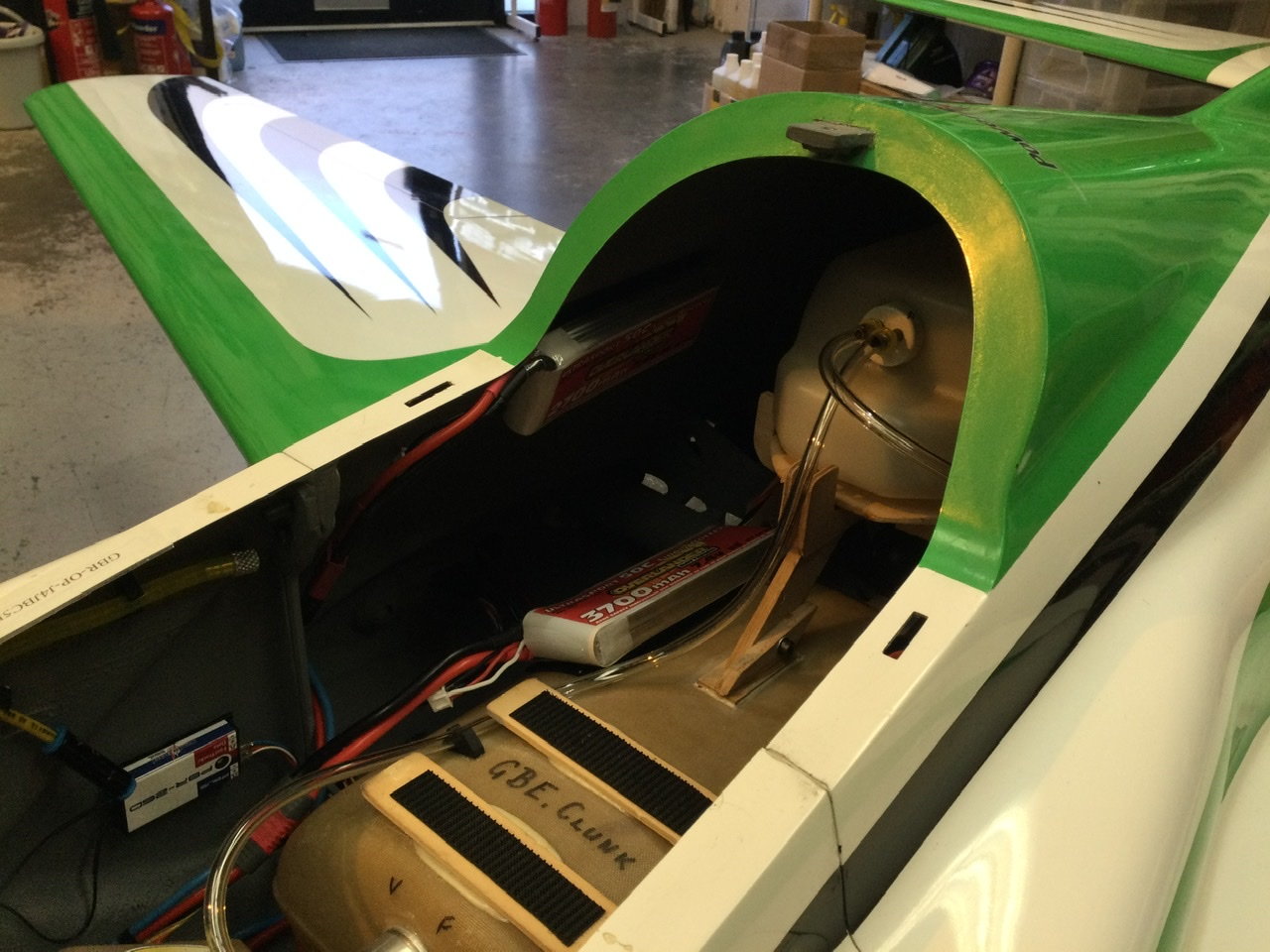

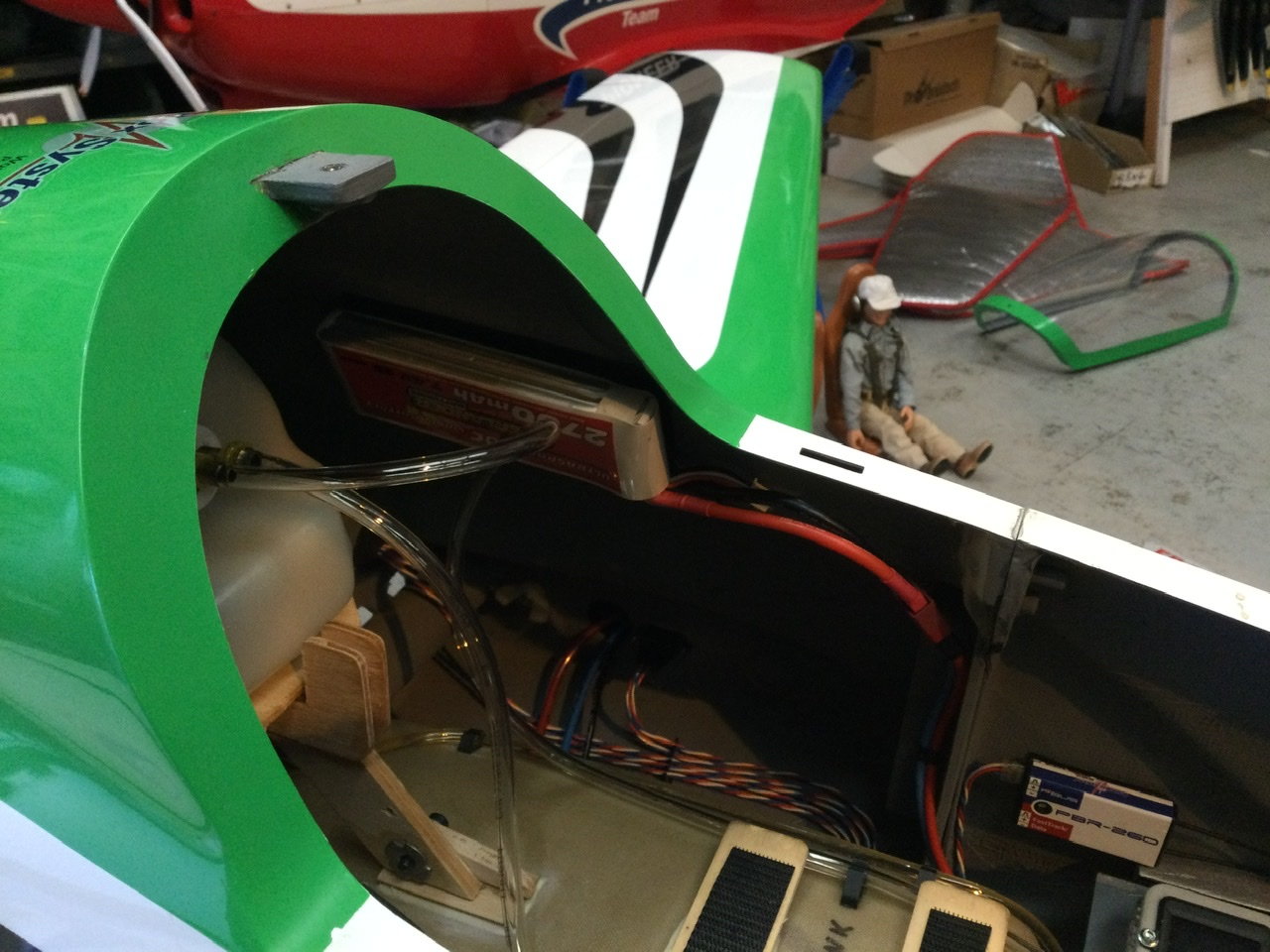

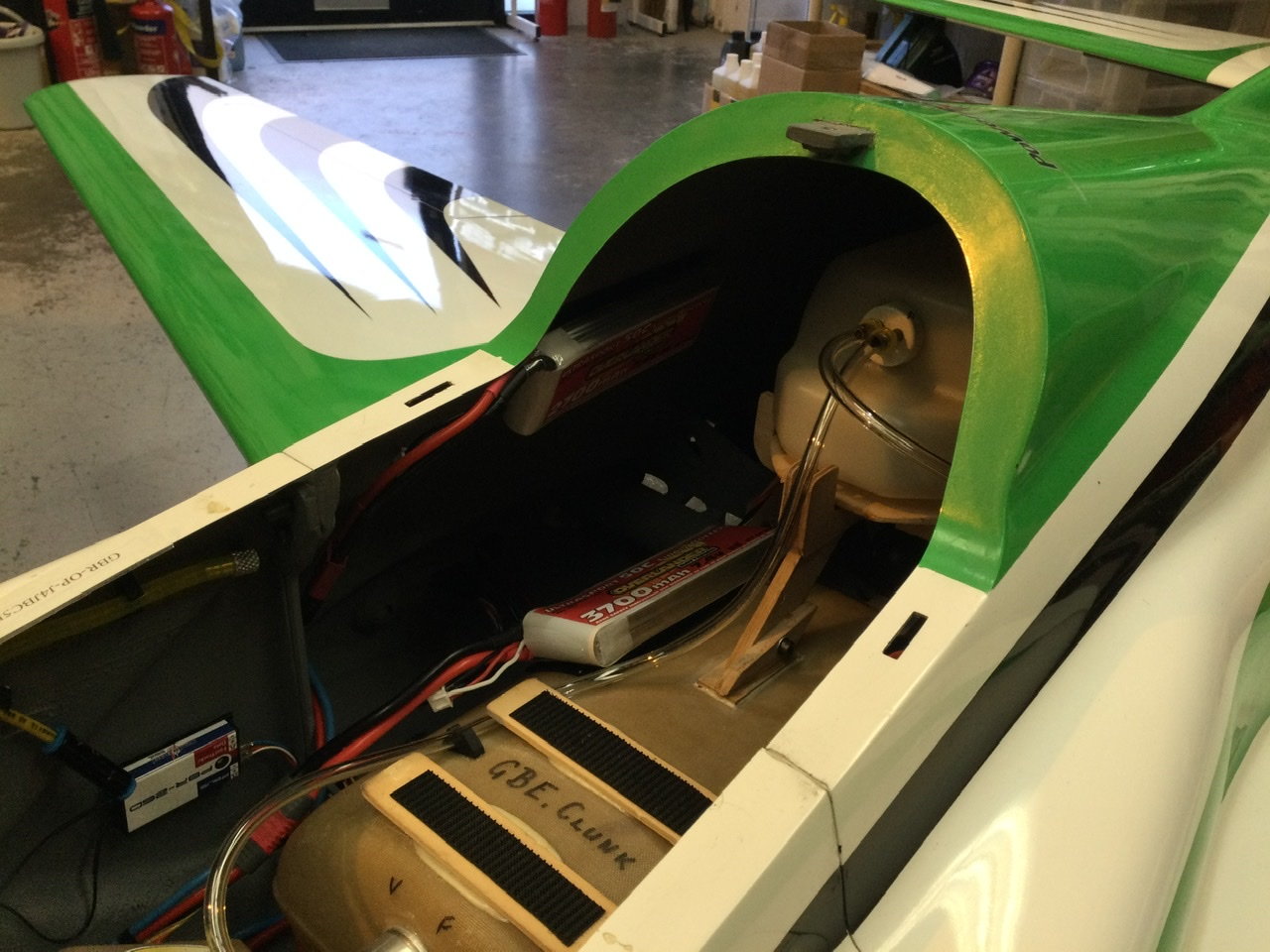

Near 10 year old CARF Viper brought up to date. It was in quite a state when it came to me for a running issue. Cleaned and polished, new canopy, totally ripped out and re wired with Powerbox wire, Mercury fitted, changed to Core. Fuel system was rebuilt and turbine serviced at JetCat. Ready for another 10 years!

The following 2 users liked this post by Dave Wilshere:

DenisFerrari (01-20-2023),

paulhat (01-20-2023)

The following users liked this post:

DenisFerrari (04-03-2023)

#710

Jim

Yep…probably don’t even need to be on the airfield 🙂 Set up correctly they are just like flying a leather arm chair. The owner will be shocked when he next flies it as I moved around 12oz of batteries from the nose and put them by the fuel tank! It flies even better with a correct balance.

Bob, no CARF Viper’s are all 2.6m

Yep…probably don’t even need to be on the airfield 🙂 Set up correctly they are just like flying a leather arm chair. The owner will be shocked when he next flies it as I moved around 12oz of batteries from the nose and put them by the fuel tank! It flies even better with a correct balance.

Bob, no CARF Viper’s are all 2.6m

The following users liked this post:

DenisFerrari (04-03-2023)

#711

Join Date: Jun 2004

Location: Alice Springs, AUSTRALIA

Posts: 191

Likes: 0

Received 0 Likes

on

0 Posts

Can anyone help with spar position in the wing please and how you routed the cable? I’d like to install Unilight nav/strobe units on the ends of the wings but I noticed the wing is sealed outboard of the aileron servo. I also want to make sure I’m either in front or behind the spar when I cut a slot in the wingtip. Any help would be appreciated.

The following 2 users liked this post by Dave Wilshere:

DenisFerrari (01-08-2024),

Hans Hilmar (01-08-2024)

The following users liked this post:

Bob_B (01-09-2024)

#714

There was a cross wind that day from memory, but slow turns with a jet is all about the rudder…it’s why so many run into trouble trying to fly slow, they just use aileron!

The following users liked this post:

DenisFerrari (01-11-2024)

#715

My Feedback: (1)

Can anyone help with spar position in the wing please and how you routed the cable? I’d like to install Unilight nav/strobe units on the ends of the wings but I noticed the wing is sealed outboard of the aileron servo. I also want to make sure I’m either in front or behind the spar when I cut a slot in the wingtip. Any help would be appreciated.

https://carf-models.com/en/products/viper-mk2

#716

Senior Member

Wondering if anyone has or can take a pic of their Electron nose gear/servo/linkage setup? I pulled my ER-40's from a Carf Hawk and contacted Electron as to what needed to be changed for this Viper and received the parts. For the nose gear, all that Adrian from Electron said needed to be changed was the servo mount which is offset to lower the servo. Even with that I have to mount the servo from below the mount(not pass the servo body through the mount) for the servo arm and linkage to clear the fuse skin and it's still very close. Just curious if I'm missing something mechanically. Thanks.

#717

My Feedback: (1)

Just need at little confirmation here to be sure I get this right, trying to use Daves method to balance my Viper. Does it sound correct that I will end up with batteries mounted approx. at back seat (Front part of Fuel tank) or I'm I way off here?

Flying now with batteries mounted next to front gear, plane flies fine but seems nose heavy when landing so want to move CG further back.

Thank you so much in advance.

Last edited by Hans Hilmar; 08-07-2024 at 12:38 AM.

The following users liked this post:

DenisFerrari (08-10-2024)

#721

My Feedback: (1)

Hi,

What servo torque is needed for the flaps and elevators? I imagine the flaps need more torque. I have some 355oz servos that I am thinking to use in the stab and 550oz for the flaps.

This airplane has been around a long time and servos have gotten much more powerful since then.

Thanks

What servo torque is needed for the flaps and elevators? I imagine the flaps need more torque. I have some 355oz servos that I am thinking to use in the stab and 550oz for the flaps.

This airplane has been around a long time and servos have gotten much more powerful since then.

Thanks

#723

My Feedback: (1)

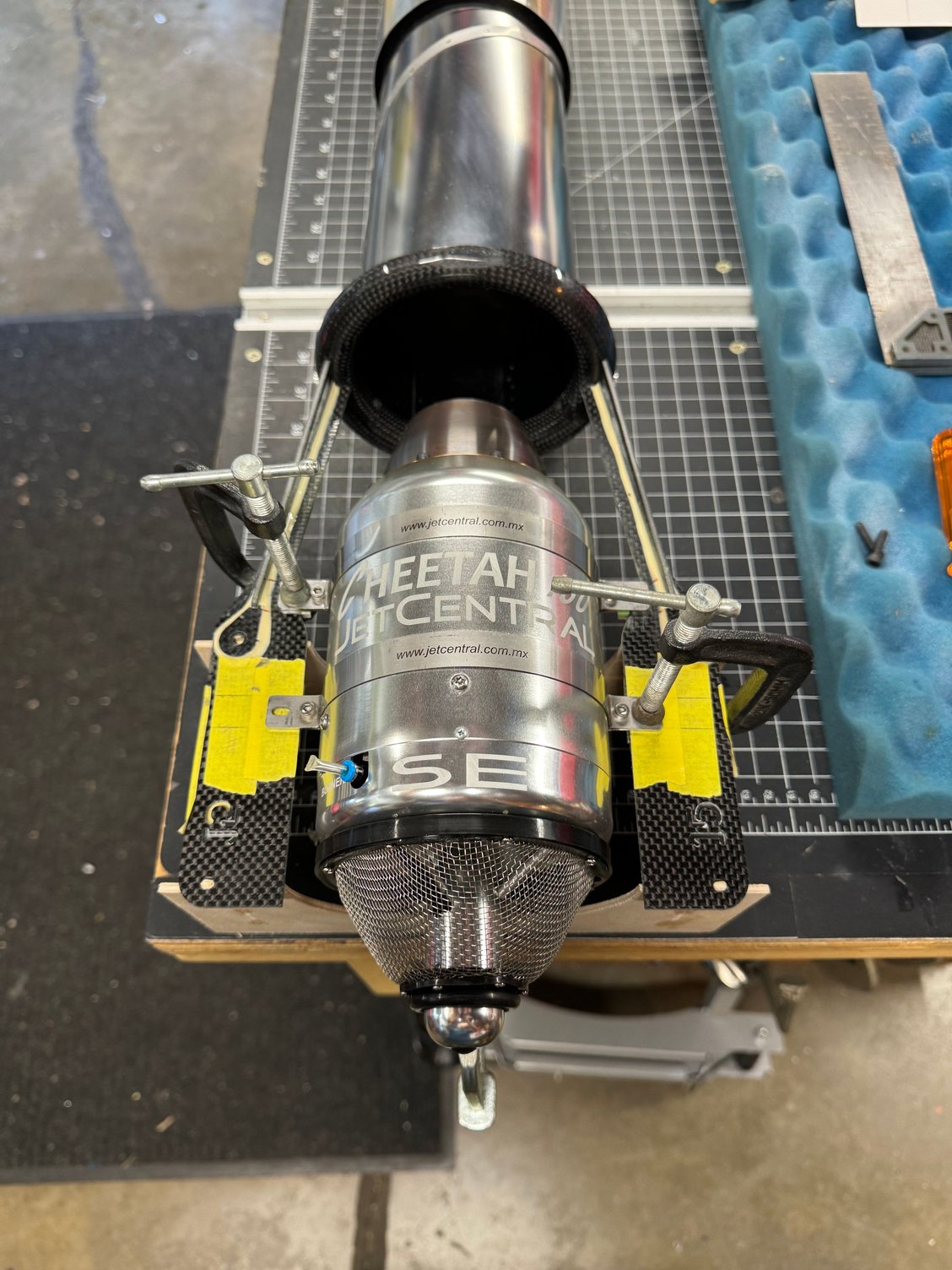

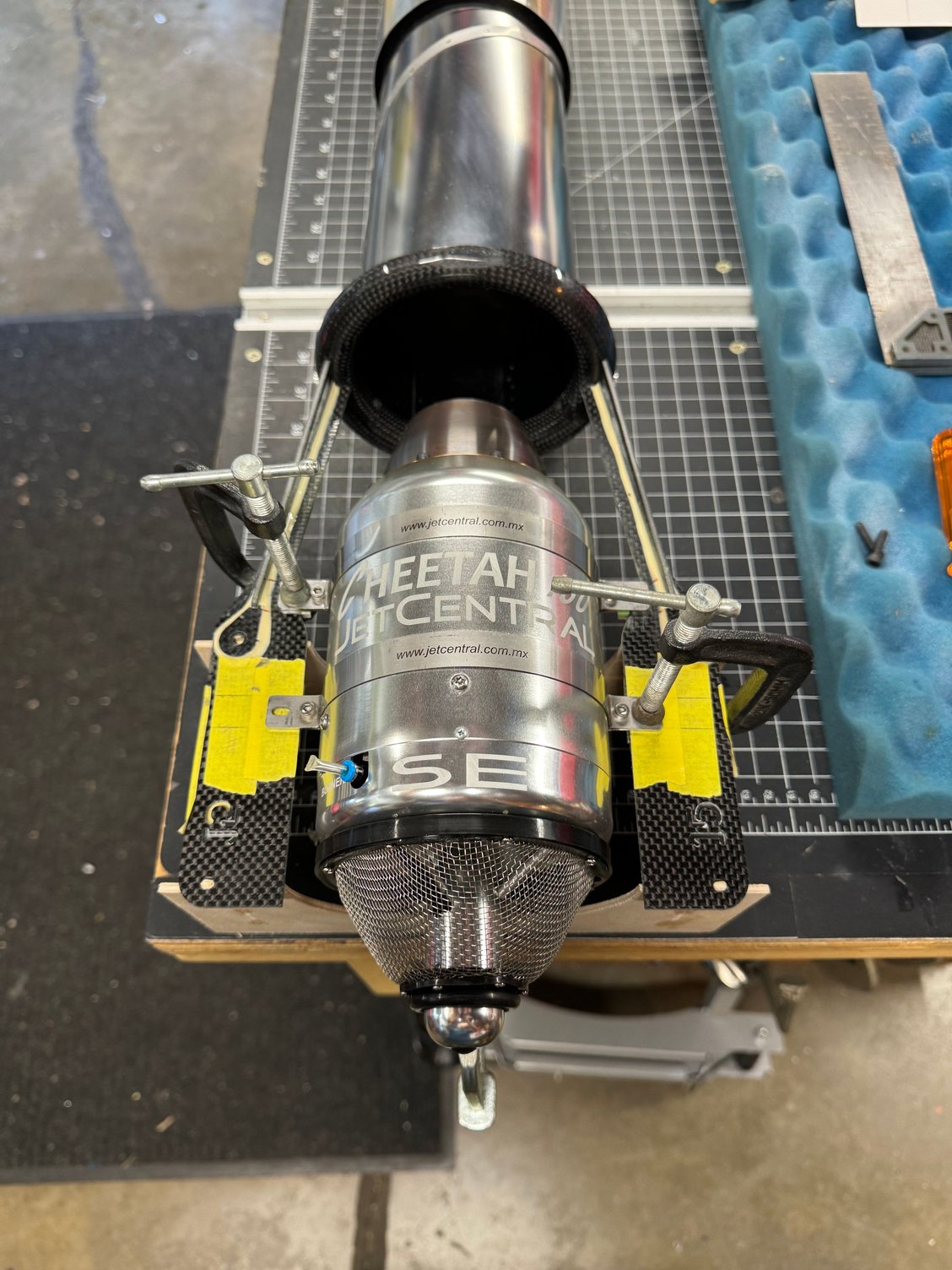

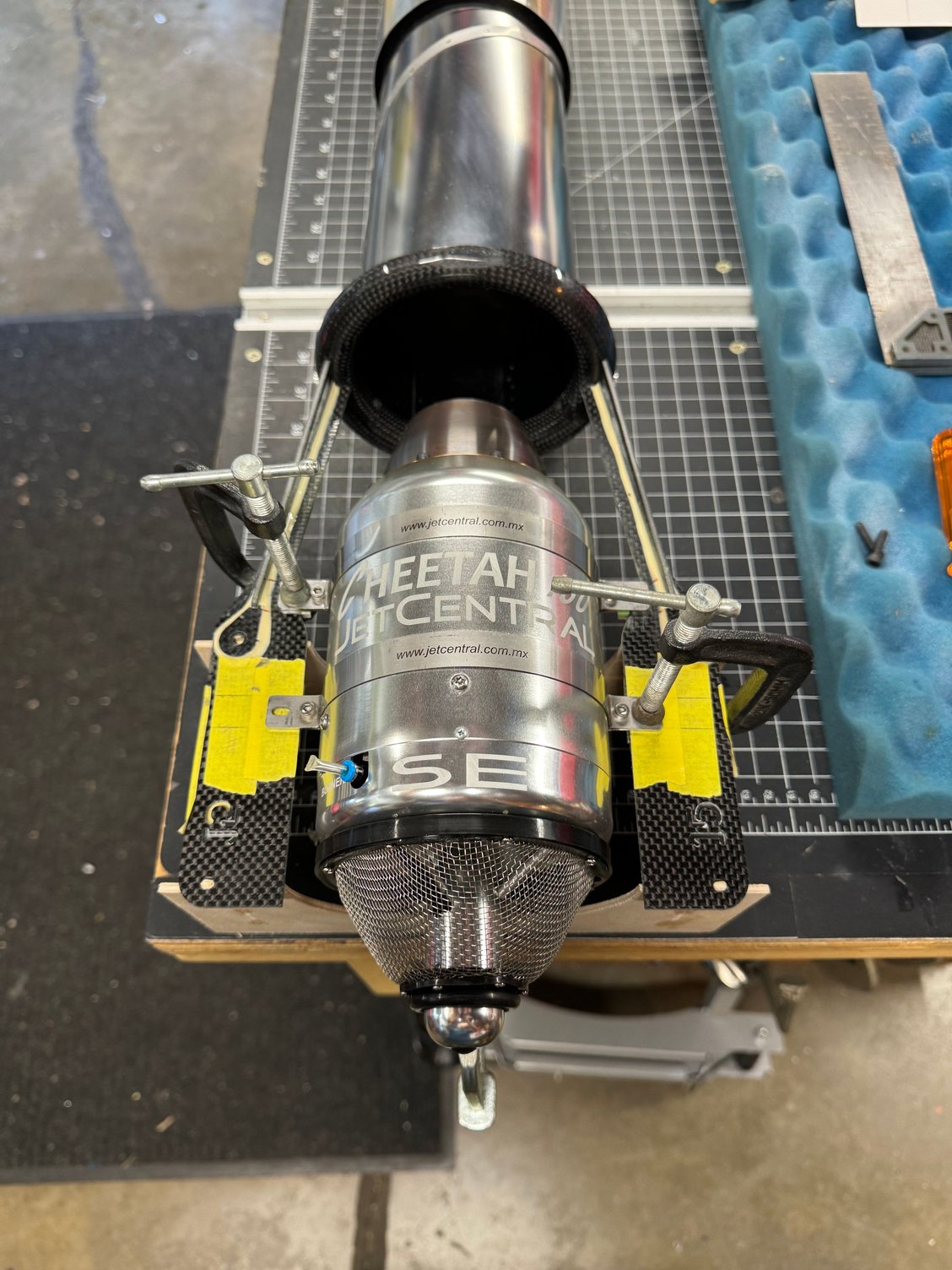

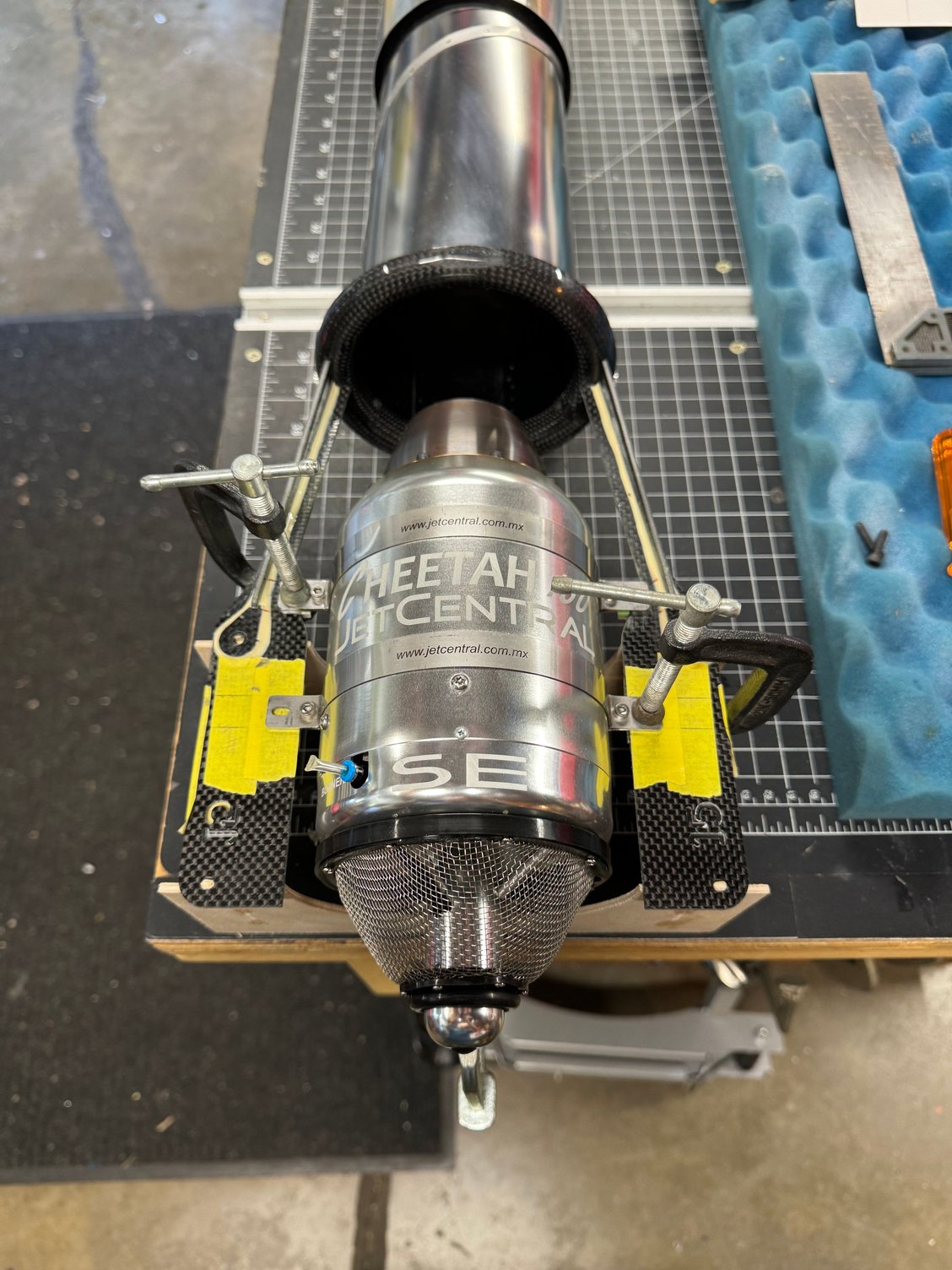

I started to build my Viper. Thanks to Elad for getting it so quickly -I ordered it on Monday and picked it up Friday. It took a little more than a week for the retracts, tank and pipe to come from Germany.

The factory photos of the Pioneer scheme do not represent how good it looks in real life. Actually, it was my least favorite scheme, until I got it. Two other fellows have the Cayman scheme and I needed something different.

It is amazing to me how perfect the paint lines line up. The parts are coming out of separate molds and are painted in the molds.

The pipe system is quite clever but can be improved by having more area to attached the turbine mounts. I had to graft on extensions for the rear bolts.

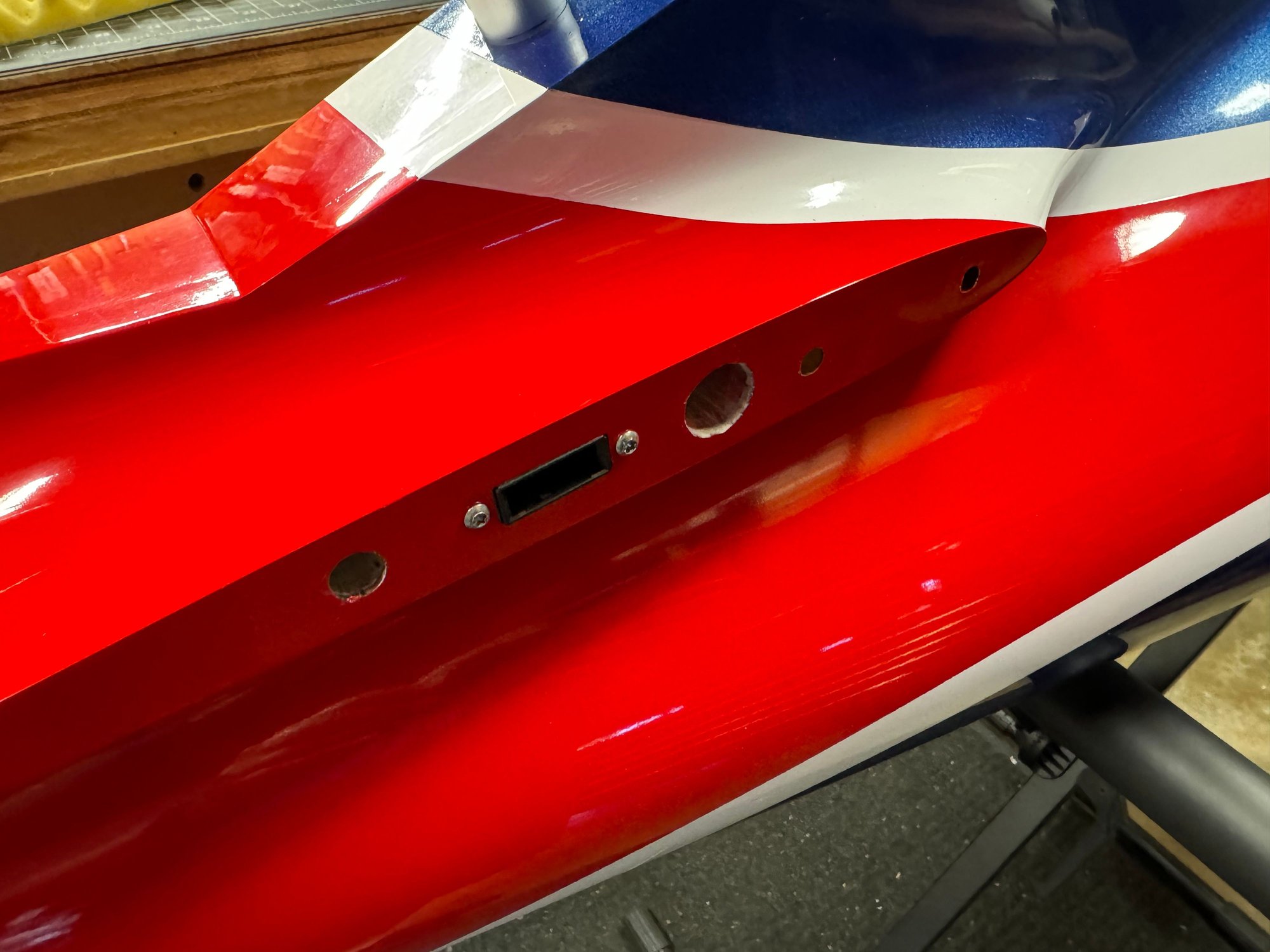

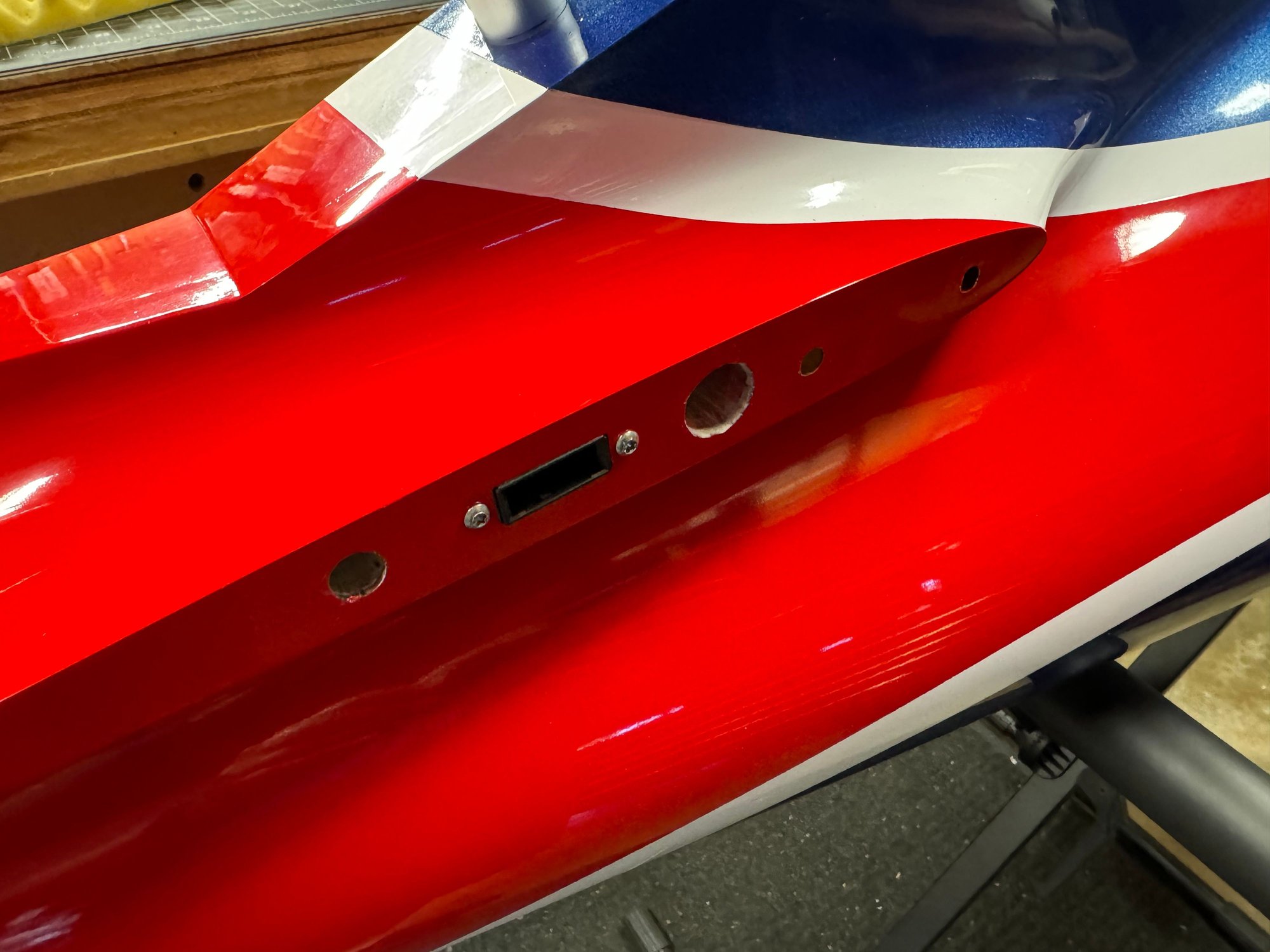

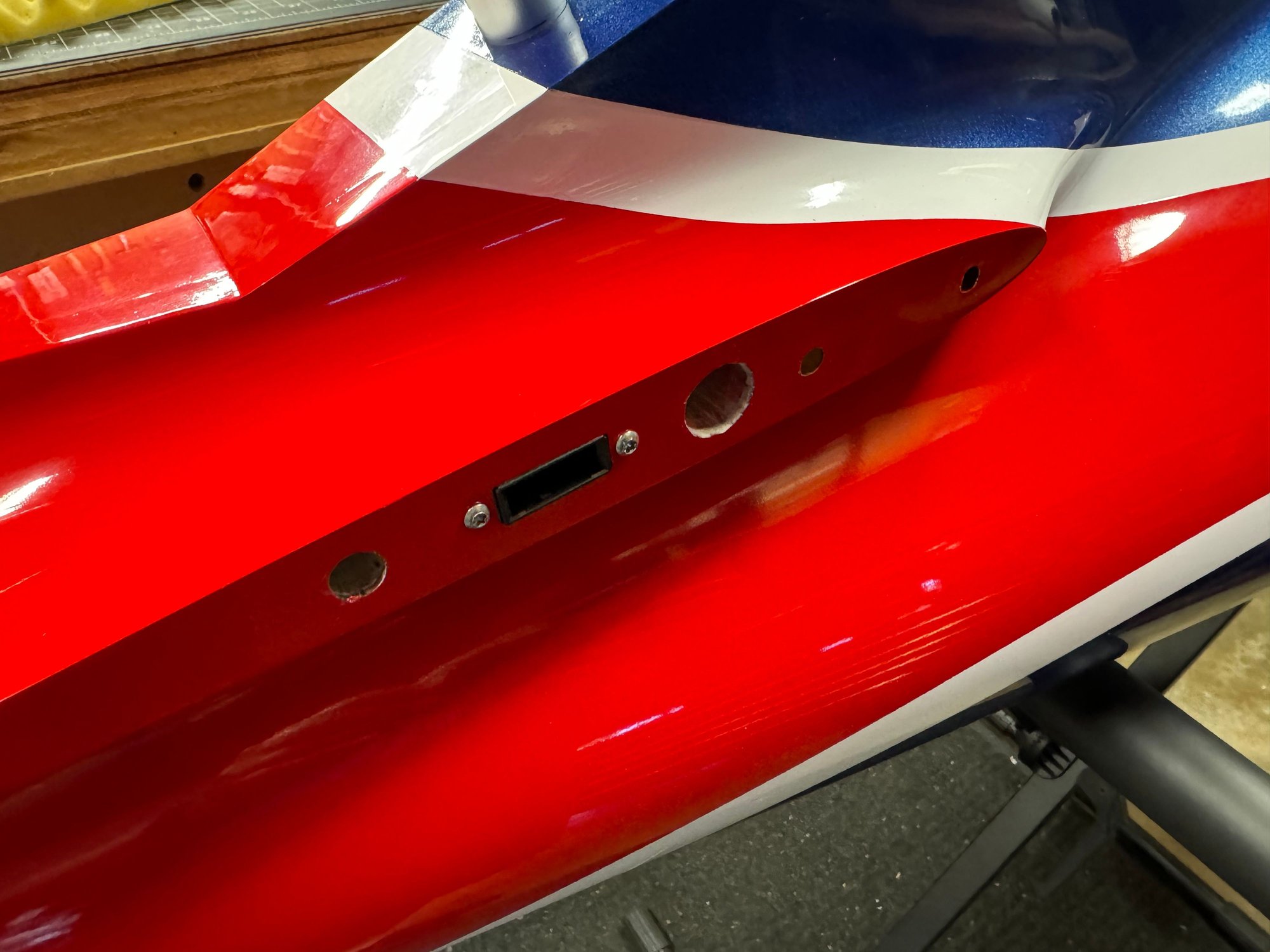

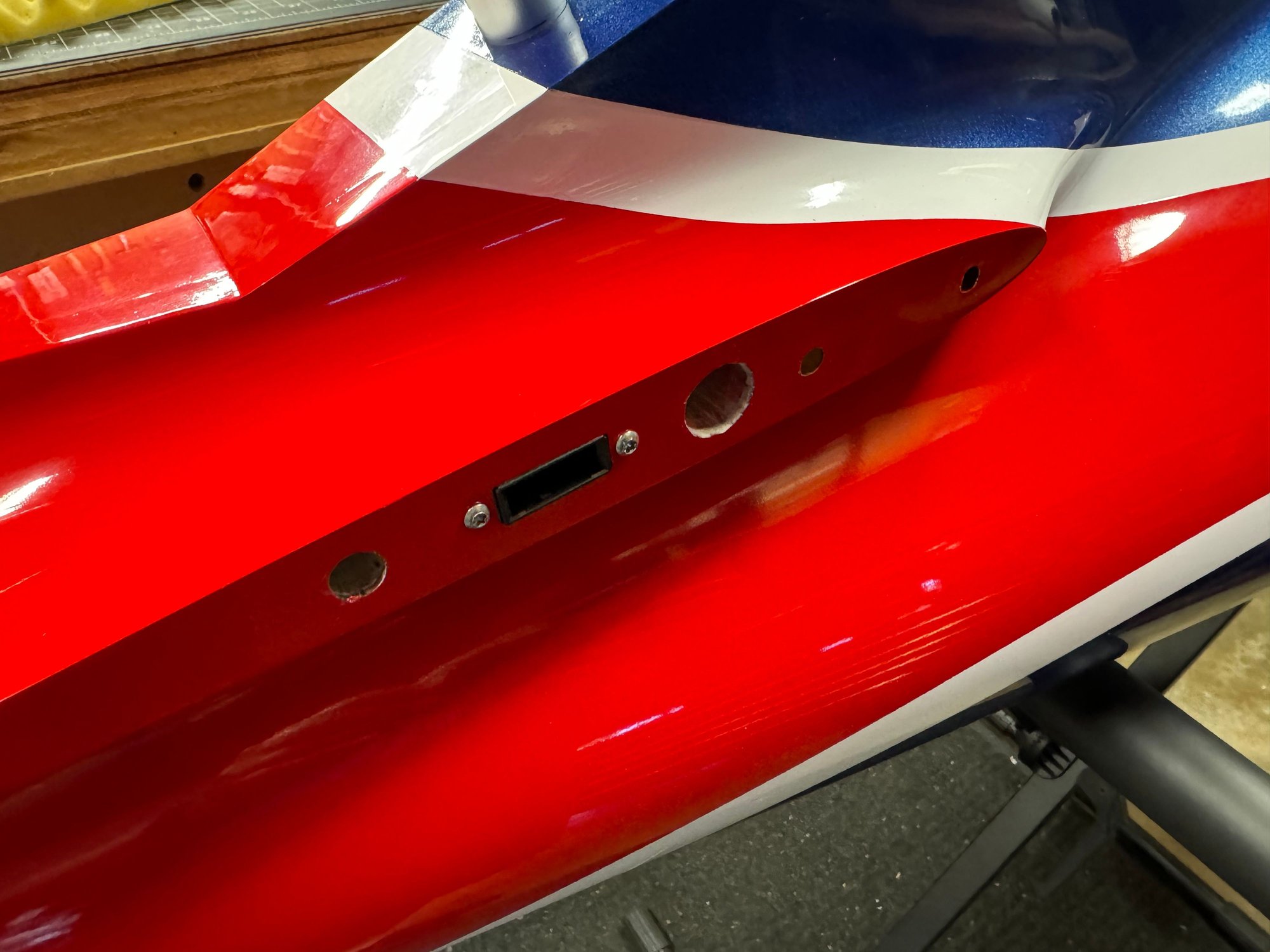

Apparently Inspector 14C left early the day they checked my model - as the wheel well cut-outs on the fuselage are absent. Ha, more fun for me.

The paint work is amazing.

See how the rear tabs are where there is no material to bolt to.

Added aluminum tabs to bolt to.

Where are the wheels supposed to go?

AMP Dynamic 3100 series connectors

Rudder wire connector.

The factory photos of the Pioneer scheme do not represent how good it looks in real life. Actually, it was my least favorite scheme, until I got it. Two other fellows have the Cayman scheme and I needed something different.

It is amazing to me how perfect the paint lines line up. The parts are coming out of separate molds and are painted in the molds.

The pipe system is quite clever but can be improved by having more area to attached the turbine mounts. I had to graft on extensions for the rear bolts.

Apparently Inspector 14C left early the day they checked my model - as the wheel well cut-outs on the fuselage are absent. Ha, more fun for me.

The paint work is amazing.

See how the rear tabs are where there is no material to bolt to.

Added aluminum tabs to bolt to.

Where are the wheels supposed to go?

AMP Dynamic 3100 series connectors

Rudder wire connector.

#724

Senior Member

I started to build my Viper. Thanks to Elad for getting it so quickly -I ordered it on Monday and picked it up Friday. It took a little more than a week for the retracts, tank and pipe to come from Germany.

The factory photos of the Pioneer scheme do not represent how good it looks in real life. Actually, it was my least favorite scheme, until I got it. Two other fellows have the Cayman scheme and I needed something different.

It is amazing to me how perfect the paint lines line up. The parts are coming out of separate molds and are painted in the molds.

The pipe system is quite clever but can be improved by having more area to attached the turbine mounts. I had to graft on extensions for the rear bolts.

Apparently Inspector 14C left early the day they checked my model - as the wheel well cut-outs on the fuselage are absent. Ha, more fun for me.

The paint work is amazing.

See how the rear tabs are where there is no material to bolt to.

Added aluminum tabs to bolt to.

Where are the wheels supposed to go?

AMP Dynamic 3100 series connectors

Rudder wire connector.

The factory photos of the Pioneer scheme do not represent how good it looks in real life. Actually, it was my least favorite scheme, until I got it. Two other fellows have the Cayman scheme and I needed something different.

It is amazing to me how perfect the paint lines line up. The parts are coming out of separate molds and are painted in the molds.

The pipe system is quite clever but can be improved by having more area to attached the turbine mounts. I had to graft on extensions for the rear bolts.

Apparently Inspector 14C left early the day they checked my model - as the wheel well cut-outs on the fuselage are absent. Ha, more fun for me.

The paint work is amazing.

See how the rear tabs are where there is no material to bolt to.

Added aluminum tabs to bolt to.

Where are the wheels supposed to go?

AMP Dynamic 3100 series connectors

Rudder wire connector.

#725

My Feedback: (1)

Hi,

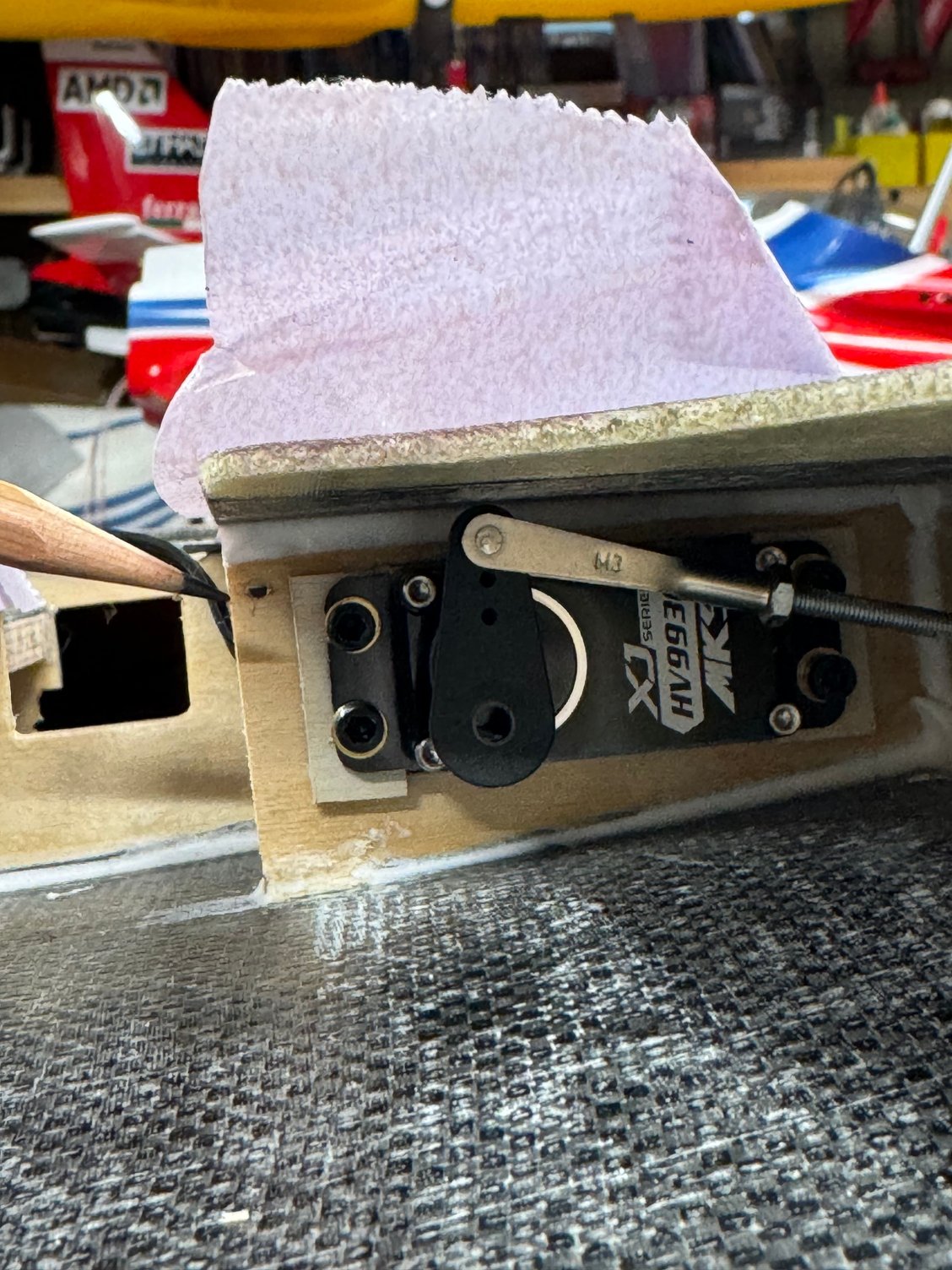

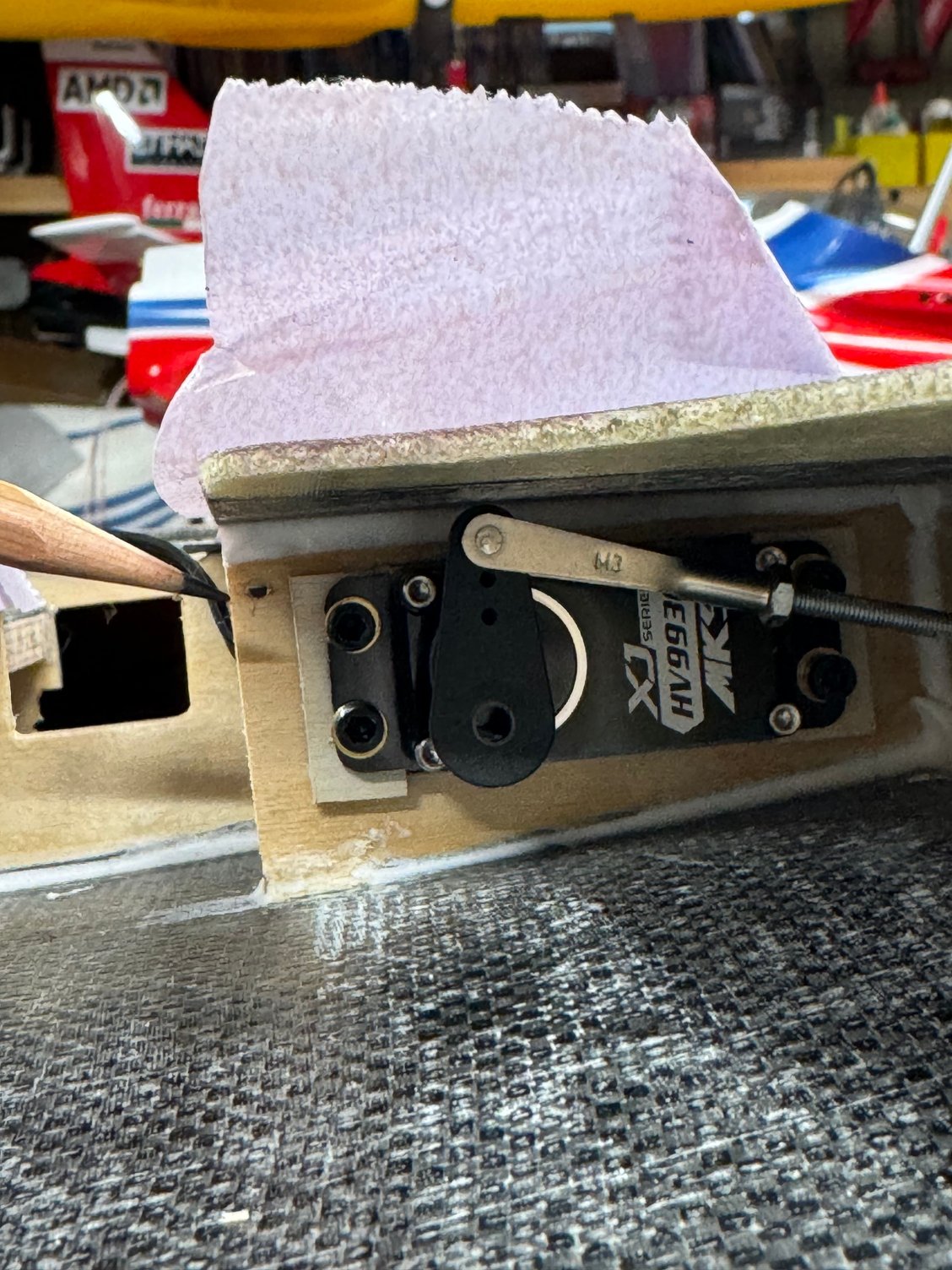

Does the right and left flap servos go in the same way? So the servo arm points towards the bottom of the wing when the flaps are up.

My right wing went right together like that. On the left wing it appears the flap mounting rib is glued in the opposite way and the servo arm does not clear the wing. It does fit the opposite way either. I've never seen an airplane with flap servo linkages set up differently for each side.

Right wing works (top of wing is down in photo)

Left wing - no joy (top of wing is down in photo)

Does the right and left flap servos go in the same way? So the servo arm points towards the bottom of the wing when the flaps are up.

My right wing went right together like that. On the left wing it appears the flap mounting rib is glued in the opposite way and the servo arm does not clear the wing. It does fit the opposite way either. I've never seen an airplane with flap servo linkages set up differently for each side.

Right wing works (top of wing is down in photo)

Left wing - no joy (top of wing is down in photo)