Finishing an old big block Maxx project!

#26

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Well, time for a short update. I got the engine in the mail today and man does it look nice! The Motor Saver T Maxx filter I have also fits right on the LRP, so I can re use that, which is awesome. I also got my Lunsford Racing titanium A arm hinge pins to replace my bent up stockers, and the Revo 40 tooth spur gear. I set to work, first installing the hinge pins, then mounting the engine and pipe. After getting everything mocked up, I noticed a few issues that I will have to deal with. Firstly, the Revo spur is too small (It was worth a shot

and man does it look nice! The Motor Saver T Maxx filter I have also fits right on the LRP, so I can re use that, which is awesome. I also got my Lunsford Racing titanium A arm hinge pins to replace my bent up stockers, and the Revo 40 tooth spur gear. I set to work, first installing the hinge pins, then mounting the engine and pipe. After getting everything mocked up, I noticed a few issues that I will have to deal with. Firstly, the Revo spur is too small (It was worth a shot ), the engine mount slots would have to be slotted a further 1/4" or so to reach the clutch bell, and then the pipe would mount in a weird looking way that I don't like, so hopefully the MGT 8.0 slipper fits on the tranny shaft. The pipe is way longer than I expected, so the receiver box is going to have to be re mounted either sideways in the factory location, or where the stock fuel tank was. My throttle linkage from the bell crank was also too short to reach the massive carb on this engine and it was hitting the pipe, so I put the bell crank in the holes that are on the other side of the chassis. This worked for reaching the carb and opening it all the way, but now the linkage between the servo and bell crank is too short! So I will have to leave the bell crank on the left side of the truck, and get a longer throttle rod to reach all the way. Then I should be able to flip the braking arm over to the opposite side and all should work well there.

), the engine mount slots would have to be slotted a further 1/4" or so to reach the clutch bell, and then the pipe would mount in a weird looking way that I don't like, so hopefully the MGT 8.0 slipper fits on the tranny shaft. The pipe is way longer than I expected, so the receiver box is going to have to be re mounted either sideways in the factory location, or where the stock fuel tank was. My throttle linkage from the bell crank was also too short to reach the massive carb on this engine and it was hitting the pipe, so I put the bell crank in the holes that are on the other side of the chassis. This worked for reaching the carb and opening it all the way, but now the linkage between the servo and bell crank is too short! So I will have to leave the bell crank on the left side of the truck, and get a longer throttle rod to reach all the way. Then I should be able to flip the braking arm over to the opposite side and all should work well there.

But I am still snagged in two areas after sorting that out. The Ofna 9.5 Pro fuel tank I ordered can no longer go where the stock one was due to the throttle linkage being there now, and the receiver box will not fit in front of the pipe unless I turn it 90 degrees and mount it that way. I am going to have to delete the factory battery box, and go with a hump pack so I can mount the new fuel tank in place of it. I should be able to bend the new throttle rod to clear the tank and get to the bell crank. The way I see it is I have two options, turn the receiver box sideways and re mount it in the factory location, or put it where the stock fuel tank was. If I move the receiver to the back, I could mount the hump pack in the front where the receiver was. The only issue with this idea is that the servo wires would likely be too short and I would need extensions to reach the back of the chassis. I think turning the receiver sideways and mounting the hump pack on the rear would be better. Would the new T Maxx receiver box be a good idea to use for this? I have seen them with power switches mounted on them too, does Traxxas make a drop in switch that goes in that little square opening for the newer ones? I would want to liquid proof the hump pack to avoid any fuel spills burning it out, but I think I could do that by coating it in Plasti Dip, and mounting it on some foam to isolate it from vibrations. I think this way would be the best way to do it. Putting the receiver next to the engine doesn't sound too safe for it to me. I made a little drawing of my ideal plan, always makes it easier for me anyways to see it in some form of a blueprint. What do you guys think? Also, any recommendations on a cheap battery pack that comes with a charger?

And of course, here are a few photos of the engine fresh out of the box next to the old TRX 2.5R, enjoy!

and man does it look nice! The Motor Saver T Maxx filter I have also fits right on the LRP, so I can re use that, which is awesome. I also got my Lunsford Racing titanium A arm hinge pins to replace my bent up stockers, and the Revo 40 tooth spur gear. I set to work, first installing the hinge pins, then mounting the engine and pipe. After getting everything mocked up, I noticed a few issues that I will have to deal with. Firstly, the Revo spur is too small (It was worth a shot

and man does it look nice! The Motor Saver T Maxx filter I have also fits right on the LRP, so I can re use that, which is awesome. I also got my Lunsford Racing titanium A arm hinge pins to replace my bent up stockers, and the Revo 40 tooth spur gear. I set to work, first installing the hinge pins, then mounting the engine and pipe. After getting everything mocked up, I noticed a few issues that I will have to deal with. Firstly, the Revo spur is too small (It was worth a shot ), the engine mount slots would have to be slotted a further 1/4" or so to reach the clutch bell, and then the pipe would mount in a weird looking way that I don't like, so hopefully the MGT 8.0 slipper fits on the tranny shaft. The pipe is way longer than I expected, so the receiver box is going to have to be re mounted either sideways in the factory location, or where the stock fuel tank was. My throttle linkage from the bell crank was also too short to reach the massive carb on this engine and it was hitting the pipe, so I put the bell crank in the holes that are on the other side of the chassis. This worked for reaching the carb and opening it all the way, but now the linkage between the servo and bell crank is too short! So I will have to leave the bell crank on the left side of the truck, and get a longer throttle rod to reach all the way. Then I should be able to flip the braking arm over to the opposite side and all should work well there.

), the engine mount slots would have to be slotted a further 1/4" or so to reach the clutch bell, and then the pipe would mount in a weird looking way that I don't like, so hopefully the MGT 8.0 slipper fits on the tranny shaft. The pipe is way longer than I expected, so the receiver box is going to have to be re mounted either sideways in the factory location, or where the stock fuel tank was. My throttle linkage from the bell crank was also too short to reach the massive carb on this engine and it was hitting the pipe, so I put the bell crank in the holes that are on the other side of the chassis. This worked for reaching the carb and opening it all the way, but now the linkage between the servo and bell crank is too short! So I will have to leave the bell crank on the left side of the truck, and get a longer throttle rod to reach all the way. Then I should be able to flip the braking arm over to the opposite side and all should work well there.But I am still snagged in two areas after sorting that out. The Ofna 9.5 Pro fuel tank I ordered can no longer go where the stock one was due to the throttle linkage being there now, and the receiver box will not fit in front of the pipe unless I turn it 90 degrees and mount it that way. I am going to have to delete the factory battery box, and go with a hump pack so I can mount the new fuel tank in place of it. I should be able to bend the new throttle rod to clear the tank and get to the bell crank. The way I see it is I have two options, turn the receiver box sideways and re mount it in the factory location, or put it where the stock fuel tank was. If I move the receiver to the back, I could mount the hump pack in the front where the receiver was. The only issue with this idea is that the servo wires would likely be too short and I would need extensions to reach the back of the chassis. I think turning the receiver sideways and mounting the hump pack on the rear would be better. Would the new T Maxx receiver box be a good idea to use for this? I have seen them with power switches mounted on them too, does Traxxas make a drop in switch that goes in that little square opening for the newer ones? I would want to liquid proof the hump pack to avoid any fuel spills burning it out, but I think I could do that by coating it in Plasti Dip, and mounting it on some foam to isolate it from vibrations. I think this way would be the best way to do it. Putting the receiver next to the engine doesn't sound too safe for it to me. I made a little drawing of my ideal plan, always makes it easier for me anyways to see it in some form of a blueprint. What do you guys think? Also, any recommendations on a cheap battery pack that comes with a charger?

And of course, here are a few photos of the engine fresh out of the box next to the old TRX 2.5R, enjoy!

Last edited by Maxximize; 02-10-2015 at 10:49 PM.

#27

Senior Member

My Feedback: (11)

Have a look at your header then take a look online at other available headers. You may be able to find a different header that will bring the pipe rearward. I ran into this problem on one of big block Maxx's. It was my cheap Maxx built from leftovers that included a plastic Savage pipe. Since it was light I just spaced it higher off the chassis. I'd turn the rx box or try to find a smaller one to keep it up front. The grey rx box is lower on the pipe side so you could raise the pipe a little to clear the box and not be as high.

As for the battery, consider a flat pack and mounting it under the chassis. I made an aluminum skid plate that held the battery using 4 screws the chassis was drilled and tapped for, not fun with titanium HCR chassis. Either that or a hump pack mounted towards the front with the fuel tank behind it. You can see the black flatnpack on the under side of the chassis in the pic I posted on the previous page. With the Savage tank I had room to move the rx box to where the battery box used to be.

As for the battery, consider a flat pack and mounting it under the chassis. I made an aluminum skid plate that held the battery using 4 screws the chassis was drilled and tapped for, not fun with titanium HCR chassis. Either that or a hump pack mounted towards the front with the fuel tank behind it. You can see the black flatnpack on the under side of the chassis in the pic I posted on the previous page. With the Savage tank I had room to move the rx box to where the battery box used to be.

#28

Im not sure if this will help,an not sure it can be done with this engine.They use to cut the crankshaft off

at the threads,an add a shorter clutch bell shaft on,on other vehicles that took the shorter crankshaft.

If this is possible,you will gain alittle bit more clearance for the header.I would check into it first,an see

if this can be done on that crankshaft.

I have a part that I can show you what they look like...

at the threads,an add a shorter clutch bell shaft on,on other vehicles that took the shorter crankshaft.

If this is possible,you will gain alittle bit more clearance for the header.I would check into it first,an see

if this can be done on that crankshaft.

I have a part that I can show you what they look like...

Last edited by cbaker65; 02-11-2015 at 04:35 PM.

#29

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Well, I got the MGT spur, and it also does not fit. Again, worth a try. I am back to square one with my gearing issue again. I have decided I am just going to scrap the old tranny in favor of the 3.3 gray tranny. I have read that with a T Maxx 4909 FOC kit output shaft installed in a 4907/4908 tranny, you can re use your old style hex brakes and use the same center shafts as the black tranny uses, so I could still use my rear dogbone and upgrade my center front one if needed. It also appears to work with the newer spec smaller spur gears instead of the huge 72 tooth gear on the old one, so I could just use the Revo spurs and Savage clutch bell as the 40 tooth Revo gear is about the same size as a T Maxx 54 tooth spur and the Savage clutch is about the same as a 24 tooth T Maxx clutch. I am still iffy on the final gear ratio, but I want to make this project simple to work with in the future when stuff breaks, so factory Traxxas parts are a plus for me. It appears that this is what quite a few people do with big block T Maxx's, so I feel a little safer about it. I also hear that you can change the internal gearing on the 3.3 tranny by just swapping the gears out, which would also be nice. Here's a link about using the new 3.3 tranny in an aftermarket chassis with the FOC kit I mentioned. Parts will be about $60, and will make this go smoother I'm thinking.

As for the pipe, here's a pic of it on the truck with the pipe mocked up on the chassis and the engine bolted down tight for a better view.

I'm thinking maybe a buggy header like this one might be the way to go. It looks like it has multiple spring holes so it should mount in some way to my Savage pipe, which only has 3 holes. As long as it still exits out the bottom of the truck, I'll be happy with it. Once I get my new receiver box I can test fit it and see if it will work without a new header. Or turn it sideways too. As far as batteries go, I already ordered an Ofna NiMH hump pack I wish I would have seen your post before I did that, but the price was hard to beat. It was $17 and it comes with an overnight charger, too. I like your set up better than what I'll probably have to do with the hump pack. I'm still thinking that with a thick foam pad, it will do ok in the back of the truck. I could also try and fit it in the empty reverse servo spot up front, that would probably work best for my situation.

I wish I would have seen your post before I did that, but the price was hard to beat. It was $17 and it comes with an overnight charger, too. I like your set up better than what I'll probably have to do with the hump pack. I'm still thinking that with a thick foam pad, it will do ok in the back of the truck. I could also try and fit it in the empty reverse servo spot up front, that would probably work best for my situation.

So anyways, I've got a new 4907 tranny and the 5195 FOC kit ordered now along with the hump pack, Ofna fuel tank and posts, and the Traxxas y harness with receiver box. The last piece of the truck that I know will have to be upgraded are the diffs, which I will replace when they blow out. Other than that, I may get some beefier springs on the corners, and eventually a new steering servo and center frotn dogbone or CVD. The header is still a maybe, we'll see when I get the new receiver box how it fits as is.

As for the pipe, here's a pic of it on the truck with the pipe mocked up on the chassis and the engine bolted down tight for a better view.

I'm thinking maybe a buggy header like this one might be the way to go. It looks like it has multiple spring holes so it should mount in some way to my Savage pipe, which only has 3 holes. As long as it still exits out the bottom of the truck, I'll be happy with it. Once I get my new receiver box I can test fit it and see if it will work without a new header. Or turn it sideways too. As far as batteries go, I already ordered an Ofna NiMH hump pack

I wish I would have seen your post before I did that, but the price was hard to beat. It was $17 and it comes with an overnight charger, too. I like your set up better than what I'll probably have to do with the hump pack. I'm still thinking that with a thick foam pad, it will do ok in the back of the truck. I could also try and fit it in the empty reverse servo spot up front, that would probably work best for my situation.

I wish I would have seen your post before I did that, but the price was hard to beat. It was $17 and it comes with an overnight charger, too. I like your set up better than what I'll probably have to do with the hump pack. I'm still thinking that with a thick foam pad, it will do ok in the back of the truck. I could also try and fit it in the empty reverse servo spot up front, that would probably work best for my situation. So anyways, I've got a new 4907 tranny and the 5195 FOC kit ordered now along with the hump pack, Ofna fuel tank and posts, and the Traxxas y harness with receiver box. The last piece of the truck that I know will have to be upgraded are the diffs, which I will replace when they blow out. Other than that, I may get some beefier springs on the corners, and eventually a new steering servo and center frotn dogbone or CVD. The header is still a maybe, we'll see when I get the new receiver box how it fits as is.

Last edited by Maxximize; 02-11-2015 at 10:39 PM.

#30

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Well, time for another short update. I got the 4907 transmission today and installed the 5195 FOC kit in it.Once that was installed the tranny bolted right in using my existing center drive shafts . The only issue with it is that it will not use the stock brake shoes from the old tranny as the mounting holes are narrower, so I must order brake shoes for the new tranny. While I'm at it, I may as well get a new rotor for the 4909 tranny. That will mount to the hex adapter I have already and my old rotor needs replacing anyways. I also got the battery pack I ordered and it fits perfectly where the old reverse servo used to be. A little piece of foam under it with some zip ties and it should be perfect. Then I will mount the switch in the black part of the receiver box. I'm also looking into a new steering servo. The age old Cirrus CDS 751MG has had a twitching issue for years that's worse now, and it's case and mounting tabs are cracked along with the loud unusual motor noises it makes. Any recommendations for good high torque metal geared servos that are affordable?

. The only issue with it is that it will not use the stock brake shoes from the old tranny as the mounting holes are narrower, so I must order brake shoes for the new tranny. While I'm at it, I may as well get a new rotor for the 4909 tranny. That will mount to the hex adapter I have already and my old rotor needs replacing anyways. I also got the battery pack I ordered and it fits perfectly where the old reverse servo used to be. A little piece of foam under it with some zip ties and it should be perfect. Then I will mount the switch in the black part of the receiver box. I'm also looking into a new steering servo. The age old Cirrus CDS 751MG has had a twitching issue for years that's worse now, and it's case and mounting tabs are cracked along with the loud unusual motor noises it makes. Any recommendations for good high torque metal geared servos that are affordable?

There is some bad news though, too. Unfortunately the new transmission sits lower in the chassis and the case half facing the engine is closer than the old one was, so the crank will have to be trimmed down a bit. It shouldn't be a problem though as it is countersunk pretty far in. Also, the gears still aren't a perfect mesh. However they are very close so I think I can get away with just shimming the engine a little higher with some washers or engine mount spacers. I found some Ofna spacers for big blocks that should be perfect for this. If they are tall enough, it should also allow me to use smaller clutch bells if I want to. The part number is OFN30482 on the spacers. I'm not sure how tall they are, so I'll order two sets. If you guys know of other parts used to shim engines higher I'd be happy to hear! I'm also going to order the Associated Reedy 28047 header as even with the new battery box, the pipe runs into it with that Savage header. After that, the fuel tank will be mounted and the truck should be ready to go! I can see the light at the end of the tunnel Of course, here are some pics of the tranny installed and the truck's current state. A little polish on the fitting and some Dremel action and I'm there!

Of course, here are some pics of the tranny installed and the truck's current state. A little polish on the fitting and some Dremel action and I'm there!

The fuel tank and FOC kit along with posts and the harness. Finally, visual proof of what size the 9.5 pro tank is.

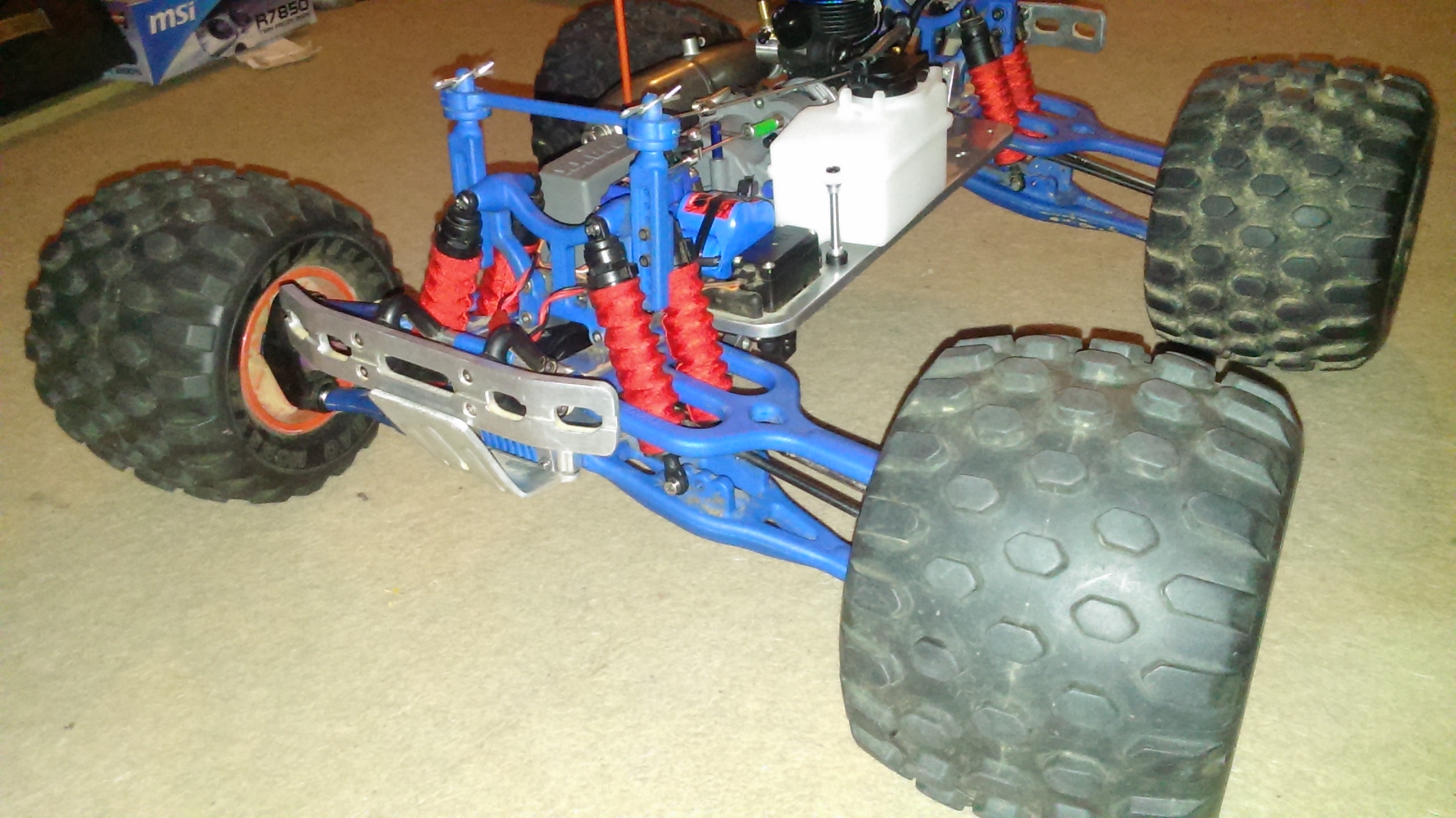

Here's a good view of the overall chassis layout with the battery sitting in it's spot out front. the fuel tank will go where the stock battery box is now. The engine is loose mounted here, if I slide it over the gear mesh hits but is not quite close enough.

I was so happy about the smaller, lower profile of the new tranny I had to post pics of the difference between it and the old one. I propped the old one up at mounting height. The spur is lower and closer to the center than the old one. The tranny also sits deeper in the chassis than the old one does. It's actually so much lower that I can run my throttle linkage over the top of the spur gear with plenty of room to spare!

. The only issue with it is that it will not use the stock brake shoes from the old tranny as the mounting holes are narrower, so I must order brake shoes for the new tranny. While I'm at it, I may as well get a new rotor for the 4909 tranny. That will mount to the hex adapter I have already and my old rotor needs replacing anyways. I also got the battery pack I ordered and it fits perfectly where the old reverse servo used to be. A little piece of foam under it with some zip ties and it should be perfect. Then I will mount the switch in the black part of the receiver box. I'm also looking into a new steering servo. The age old Cirrus CDS 751MG has had a twitching issue for years that's worse now, and it's case and mounting tabs are cracked along with the loud unusual motor noises it makes. Any recommendations for good high torque metal geared servos that are affordable?

. The only issue with it is that it will not use the stock brake shoes from the old tranny as the mounting holes are narrower, so I must order brake shoes for the new tranny. While I'm at it, I may as well get a new rotor for the 4909 tranny. That will mount to the hex adapter I have already and my old rotor needs replacing anyways. I also got the battery pack I ordered and it fits perfectly where the old reverse servo used to be. A little piece of foam under it with some zip ties and it should be perfect. Then I will mount the switch in the black part of the receiver box. I'm also looking into a new steering servo. The age old Cirrus CDS 751MG has had a twitching issue for years that's worse now, and it's case and mounting tabs are cracked along with the loud unusual motor noises it makes. Any recommendations for good high torque metal geared servos that are affordable? There is some bad news though, too. Unfortunately the new transmission sits lower in the chassis and the case half facing the engine is closer than the old one was, so the crank will have to be trimmed down a bit. It shouldn't be a problem though as it is countersunk pretty far in. Also, the gears still aren't a perfect mesh. However they are very close so I think I can get away with just shimming the engine a little higher with some washers or engine mount spacers. I found some Ofna spacers for big blocks that should be perfect for this. If they are tall enough, it should also allow me to use smaller clutch bells if I want to. The part number is OFN30482 on the spacers. I'm not sure how tall they are, so I'll order two sets. If you guys know of other parts used to shim engines higher I'd be happy to hear! I'm also going to order the Associated Reedy 28047 header as even with the new battery box, the pipe runs into it with that Savage header. After that, the fuel tank will be mounted and the truck should be ready to go! I can see the light at the end of the tunnel

Of course, here are some pics of the tranny installed and the truck's current state. A little polish on the fitting and some Dremel action and I'm there!

Of course, here are some pics of the tranny installed and the truck's current state. A little polish on the fitting and some Dremel action and I'm there!The fuel tank and FOC kit along with posts and the harness. Finally, visual proof of what size the 9.5 pro tank is.

Here's a good view of the overall chassis layout with the battery sitting in it's spot out front. the fuel tank will go where the stock battery box is now. The engine is loose mounted here, if I slide it over the gear mesh hits but is not quite close enough.

I was so happy about the smaller, lower profile of the new tranny I had to post pics of the difference between it and the old one. I propped the old one up at mounting height. The spur is lower and closer to the center than the old one. The tranny also sits deeper in the chassis than the old one does. It's actually so much lower that I can run my throttle linkage over the top of the spur gear with plenty of room to spare!

Last edited by Maxximize; 02-19-2015 at 07:50 PM.

#31

Senior Member

My Feedback: (11)

Well it's coming along. Definitely get a buggy header, it'll pull the pipe back a lot over the savage header. And you can always drill more holes for the springs in the header or pipe to get it pointed the way you want.

I'm not sure what you have on the end of your crank holding the clutchbell on but some of the "buttons" used in traditional big block applications are longer than they need to be. I had to cut the crank on both of my big block TMaxx's but I was able to reduce the amount needing to be cut by getting rid of the plastic button and using just a washer and pan head screw.

Edit: The stock brake setup on the grey trans is awesome, I wouldn't change a thing. The grey trans also has brake pads with actual friction material on them with a metal rotor/brake disc unlike the black trans with the fiber rotor and metal pads. Get the center driveshaft from the 4907, cut it down if you have to and run the stock 4907 brake disc/rotor. I ran the 4907 front center shaft on one of my big blocks, it held up without issue as the rear shaft takes most of the punishment.

I'm not sure what you have on the end of your crank holding the clutchbell on but some of the "buttons" used in traditional big block applications are longer than they need to be. I had to cut the crank on both of my big block TMaxx's but I was able to reduce the amount needing to be cut by getting rid of the plastic button and using just a washer and pan head screw.

Edit: The stock brake setup on the grey trans is awesome, I wouldn't change a thing. The grey trans also has brake pads with actual friction material on them with a metal rotor/brake disc unlike the black trans with the fiber rotor and metal pads. Get the center driveshaft from the 4907, cut it down if you have to and run the stock 4907 brake disc/rotor. I ran the 4907 front center shaft on one of my big blocks, it held up without issue as the rear shaft takes most of the punishment.

Last edited by Maj_Overdrive; 02-18-2015 at 05:06 AM.

#32

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Well, I ordered the Reedy header and the brakes I need. That particular header looks like it will pull that pipe back about an inch, so I'm hoping it will now fit without turning the receiver box. The FOC kit (TRA5195) I installed replaced the 4907 spec output shaft with a 4909 spec one which allows me to use the T Maxx 4909 brake setup. I think the 4909 disc is about the same size in diameter than the 4907/4908 one. It should use my current hex adapter, but is a metal brake disc. They have two different hex adapters listed for it, one is 4966 and the other is 4966x. I'm not sure what the difference is on those parts, but I'm guessing I have the 4966 hex on mine as my centers front shaft is original from the truck's Pro .15 days. I found that solution for the FOC kit on the traxxas forums, it's a pretty slick mod indeed! I am guessing I can upgrade my center front shaft using T Maxx 4910 CVDs if I ever need to as the output shaft is the same size as my old centers are.

My engine currently has some kind of low profile flat screw holding the clutch on. From the looks of it, I may not have to trim it if I can get a flatter screw on there. It will be pretty close to the tranny, but the screw is the only thing making it hit. If I do have to, it looks like it will only have to be trimmed 1/16" or so. I ordered an Ofna clutch bell shim kit along with my other stuff, it comes with an assortment of different washers of varying thickness. That should help out if I don't have to trim the crank down to the threading start point. The Savage clutch bell came with a little spacer that sits behind the screw to hold the clutch all the way in. I could take that to work and try and grind it down a bit too I suppose. Either way, I think I'll have all the shims I need for anything engine related now Hopefully everything will fit after these parts come.

Hopefully everything will fit after these parts come.

Also, what servos is everyone running on monster trucks these days? I'm looking for one that will out power my current Cirrus CDS 751, but doesn't cost more than $50-$60. The Cirrus does 180.5 oz-in @ 6.0V. I want one that does 200+ oz-in @6.0V that has metal gears. The two I'm looking at now are the Savox SC-0251 and the Savox SC-1256. The 1256 has 277 oz-in of torque and titanium gears, but I'm not really sure if I need that much torque. The SC-0251 has 222 oz-in and metal gears, and is half the price of the 1256.

My engine currently has some kind of low profile flat screw holding the clutch on. From the looks of it, I may not have to trim it if I can get a flatter screw on there. It will be pretty close to the tranny, but the screw is the only thing making it hit. If I do have to, it looks like it will only have to be trimmed 1/16" or so. I ordered an Ofna clutch bell shim kit along with my other stuff, it comes with an assortment of different washers of varying thickness. That should help out if I don't have to trim the crank down to the threading start point. The Savage clutch bell came with a little spacer that sits behind the screw to hold the clutch all the way in. I could take that to work and try and grind it down a bit too I suppose. Either way, I think I'll have all the shims I need for anything engine related now

Hopefully everything will fit after these parts come.

Hopefully everything will fit after these parts come.Also, what servos is everyone running on monster trucks these days? I'm looking for one that will out power my current Cirrus CDS 751, but doesn't cost more than $50-$60. The Cirrus does 180.5 oz-in @ 6.0V. I want one that does 200+ oz-in @6.0V that has metal gears. The two I'm looking at now are the Savox SC-0251 and the Savox SC-1256. The 1256 has 277 oz-in of torque and titanium gears, but I'm not really sure if I need that much torque. The SC-0251 has 222 oz-in and metal gears, and is half the price of the 1256.

Last edited by Maxximize; 02-19-2015 at 07:40 PM.

#33

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Another additional question for you guys. I am planning on re tuning my suspension for the increased weight and power of that engine. I am going back to square one with my shock oil, 50 or 60 weight on all 8 shocks for now, and am going to use 4 stronger springs in place of the 4 Traxxas white ones. The blue ones I have I believe are Trinity blue springs, the 4.5 ones I'm thinking and they will be re used. I found some Lunsford Racing titanium springs for Maxx trucks, but those look like they would be too stiff coupled with the Trinity ones. What springs would go well with the Trinity ones so I won't have to use really heavy oil and a bunch of pre-load spacers?

Last edited by Maxximize; 02-21-2015 at 02:03 AM.

#34

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Update time again! I received some miscellaneous screws, shims, and other random little parts needed. The Ofna engine mount shims (#30482) came as well, and are actually thicker than I expected them to be and fit perfectly. They are 1/8" thick, so this should allow me a lot more flex with the clutch bell size. With all 4 mounted (ordered 2 bags of 2 each), the 17 tooth bell meshes very nicely to the 40 tooth spur with room to spare, so a smaller 16 tooth one would definitely be usable. I also ordered a 19 tooth hardened clutch bell for some experimenting once the truck is running. Though I've heard of people running 18 to 20 tooth clutch bells on 3.3 trannys with a 40 tooth spur, it seems to me that would be too tall. I will try it out though to see how each one works. I also found a 42 tooth steel Revo spur made by Hot Racing, so I could try that with a hardened bell if I want to as well, though I'd rather stick to plastic. I also ordered the 4 Lunsford Racing titanium shock springs (#LNS7605) for a combo of my blue ones and those with some lighter shock oil. I hope they are not too stiff, but I want to use less pre-load spacers than I have to now so I think they might be pretty good for my application.

I also went ahead and ordered a set of E Maxx 3908 diffs. They are complete with collar and removed from a new RTR truck, and cost $60 shipped. I'm waiting on those yet, but I think my drive line should be strong enough to handle this engine now Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.

Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.

After getting all that stuff, it will be time for some crank trimming and mounting of the fuel tank and switch harness, and the truck will be ready to go! All I need then is to paint and trim the body, and wait for tolerable weather for break in

I do have some questions still though. I am still in need of a new steering servo, but truly have no idea what brands are good to use anymore. I know Hitec are good, but they're too costly for my liking. Any input on this would be awesome! Also, I think the E Maxx 3908 diffs are sealed like the 4907/4908 T Maxx ones are, but I'm not sure. If they are, do they come with silicone oil in them already? what weight oil is used in them stock if they do? And lastly, if I decide to tune them in, what is a good oil weight to start with for all around bashing?

I also went ahead and ordered a set of E Maxx 3908 diffs. They are complete with collar and removed from a new RTR truck, and cost $60 shipped. I'm waiting on those yet, but I think my drive line should be strong enough to handle this engine now

Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.

Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.After getting all that stuff, it will be time for some crank trimming and mounting of the fuel tank and switch harness, and the truck will be ready to go! All I need then is to paint and trim the body, and wait for tolerable weather for break in

I do have some questions still though. I am still in need of a new steering servo, but truly have no idea what brands are good to use anymore. I know Hitec are good, but they're too costly for my liking. Any input on this would be awesome! Also, I think the E Maxx 3908 diffs are sealed like the 4907/4908 T Maxx ones are, but I'm not sure. If they are, do they come with silicone oil in them already? what weight oil is used in them stock if they do? And lastly, if I decide to tune them in, what is a good oil weight to start with for all around bashing?

#35

Update time again! I received some miscellaneous screws, shims, and other random little parts needed. The Ofna engine mount shims (#30482) came as well, and are actually thicker than I expected them to be and fit perfectly. They are 1/8" thick, so this should allow me a lot more flex with the clutch bell size. With all 4 mounted (ordered 2 bags of 2 each), the 17 tooth bell meshes very nicely to the 40 tooth spur with room to spare, so a smaller 16 tooth one would definitely be usable. I also ordered a 19 tooth hardened clutch bell for some experimenting once the truck is running. Though I've heard of people running 18 to 20 tooth clutch bells on 3.3 trannys with a 40 tooth spur, it seems to me that would be too tall. I will try it out though to see how each one works. I also found a 42 tooth steel Revo spur made by Hot Racing, so I could try that with a hardened bell if I want to as well, though I'd rather stick to plastic. I also ordered the 4 Lunsford Racing titanium shock springs (#LNS7605) for a combo of my blue ones and those with some lighter shock oil. I hope they are not too stiff, but I want to use less pre-load spacers than I have to now so I think they might be pretty good for my application.

I also went ahead and ordered a set of E Maxx 3908 diffs. They are complete with collar and removed from a new RTR truck, and cost $60 shipped. I'm waiting on those yet, but I think my drive line should be strong enough to handle this engine now Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.

Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.

After getting all that stuff, it will be time for some crank trimming and mounting of the fuel tank and switch harness, and the truck will be ready to go! All I need then is to paint and trim the body, and wait for tolerable weather for break in

I do have some questions still though. I am still in need of a new steering servo, but truly have no idea what brands are good to use anymore. I know Hitec are good, but they're too costly for my liking. Any input on this would be awesome! Also, I think the E Maxx 3908 diffs are sealed like the 4907/4908 T Maxx ones are, but I'm not sure. If they are, do they come with silicone oil in them already? what weight oil is used in them stock if they do? And lastly, if I decide to tune them in, what is a good oil weight to start with for all around bashing?

I also went ahead and ordered a set of E Maxx 3908 diffs. They are complete with collar and removed from a new RTR truck, and cost $60 shipped. I'm waiting on those yet, but I think my drive line should be strong enough to handle this engine now

Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.

Now on that subject, I did some research and found an easy fix for the shorter pinion shafts on E Maxx diffs causing fitment issues with dogbones on a T Maxx. I found a nice little explanation by a guy on the Traxxas forums that using 4909 spec pinions makes them a much better fit for the T Maxx. I ordered 2 sets of the ring and pinion gear, part number 4981. These parts are apparently compatible with all generations of T Maxx diffs, so I have some spare ring gears for putting together a cheap 4910 Maxx truck from all my extra stuff later. They may be usable with the E Maxx diffs too, but I'm not sure on that.After getting all that stuff, it will be time for some crank trimming and mounting of the fuel tank and switch harness, and the truck will be ready to go! All I need then is to paint and trim the body, and wait for tolerable weather for break in

I do have some questions still though. I am still in need of a new steering servo, but truly have no idea what brands are good to use anymore. I know Hitec are good, but they're too costly for my liking. Any input on this would be awesome! Also, I think the E Maxx 3908 diffs are sealed like the 4907/4908 T Maxx ones are, but I'm not sure. If they are, do they come with silicone oil in them already? what weight oil is used in them stock if they do? And lastly, if I decide to tune them in, what is a good oil weight to start with for all around bashing?

I was running a 49/19,an it calmed my wheely's down to 0...

#36

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

. I'd like to find out what the final drive is on a T Maxx, but I have no idea how to calculate all the numbers and get a real answer lol.

. I'd like to find out what the final drive is on a T Maxx, but I have no idea how to calculate all the numbers and get a real answer lol.Anyways, I got all my parts in the mail now except my diffs. I worked on it a little last night with my brand new Dremel 3000 (Thanks, Mom for the Fleet Farm gift card

) and got some cutting and grinding out of the way. I have also settled on a steering servo, the Savox 1256TG. It has 280 oz-in for torque and it is around $70, not bad at all! I got the stronger Lunsford shock springs on there too, but I think the Trinity springs also might need replacing. The truck still sags under it's own weight without spacers just sitting still. I have no clue how much this thing weighs now, but I'm guessing it's pushing close to 15 pounds or so. For a stock Maxx, those Lunsford springs on each corner with 4 stock red springs would be perfect. I've read that Monster GT springs can be used with Maxx shocks so I'll order some of the firm or extra firm ones. I think that will make a nice combo with 50 weight oil all around for this things immense weight. I'm expecting my diffs this week so more to come very soon!

) and got some cutting and grinding out of the way. I have also settled on a steering servo, the Savox 1256TG. It has 280 oz-in for torque and it is around $70, not bad at all! I got the stronger Lunsford shock springs on there too, but I think the Trinity springs also might need replacing. The truck still sags under it's own weight without spacers just sitting still. I have no clue how much this thing weighs now, but I'm guessing it's pushing close to 15 pounds or so. For a stock Maxx, those Lunsford springs on each corner with 4 stock red springs would be perfect. I've read that Monster GT springs can be used with Maxx shocks so I'll order some of the firm or extra firm ones. I think that will make a nice combo with 50 weight oil all around for this things immense weight. I'm expecting my diffs this week so more to come very soon!

Last edited by Maxximize; 03-01-2015 at 09:49 PM.

#37

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Well, I got some time to work on the truck finally and I am proud to say it is done! I installed my E Maxx 3908 diffs and re oiled all my shocks as well. I went with 4 Lunsford Racing titanium T Maxx springs on the outer four shocks, and 4 Associated MGT copper extra firm springs on the insides. I used 45 weight oil in all four front shocks and 50 weight out back. I think those oil weights are a good starting point, I am running the shocks on the inner most mounting holes on the lower a arm for now. I installed the 4909 T Maxx pinions in the E Maxx diffs to make them a similar length to my old diffs. This made it possible to run my existing center rear dogbone without risking it falling out due to the shorter E Maxx pinion shafts. It also allows the use of the older stock plastic center shaft with no grinding of the shaft. Surprisingly, the diffs required no shims on the inside at all, but I had to heavily shim the outside due to the space between the outer pinion bearing and the center drive shaft. I used 6x8x.2mm diff shims in conjunction with some 6mm ID flat washers from the hardware store. I put the smaller shims against the bearing to space it away from the larger washers so they won't contact the outer edge of the bearing. This is a really nice mod option for those running a non extended Maxx who want the newer sealed diffs. This also applies to the newer 4907/4908 3.3 Maxx diffs, as they are the same size and use the same pinion shaft as the E Maxx 3908 diffs do.

The only other mods I want to do besides a new steering servo is some better shocks to replace the stock plastic ones, and possibly a dual tank mod. I am considering using an Ofna Pirate tank where the stock one used to be. It is 125cc and perfectly square so it would likely work better than the stock tank does, and fits roughly in the same area. For now I'll see what kind of run times I get on the 150cc 9.5 tank and just enjoy the truck as it is I still need to trim and paint my body and of course break the new engine in, but I'm waiting on solid warmer weather for those things. As soon as it's 50 degrees or so out for a few days in a row it will be break in time! Once I get the body painted I will post pics of it as well. I also plan on a few vids of the truck running and racing a stock 3.3 T Maxx.

I still need to trim and paint my body and of course break the new engine in, but I'm waiting on solid warmer weather for those things. As soon as it's 50 degrees or so out for a few days in a row it will be break in time! Once I get the body painted I will post pics of it as well. I also plan on a few vids of the truck running and racing a stock 3.3 T Maxx.

This was a fun project, and the truck is definitely one of a kind now! I am quite happy with the way it turned out.

Here is the list of all the major parts I used:

-LRP Z.28R Spec 3 pull start

-Motor Saver #151660 1/8 scale air filter

-HPI Savage X flywheel, clutch shoes, and clutch bell (17 tooth)

-THS Racing #825H Savage pipe with Reedy #28047 header

-ACNCM big block Maxx chassis with rear dogbone, center braces, center skid plate, and engine mount, Ofna #30282 engine mount shims

-ACNCM billet bulkheads w/ RPM bulkhead braces

-RC Raven aluminum T Maxx skid plates and bumpers

-New complete 4907 T Maxx tranny with 4909 T Maxx 5mm output shaft and 4909 brakes

-3.3 T Maxx slipper clutch with 40 tooth Revo spur gear

-E Maxx 3908 differentials with 4909 T Maxx pinions

-Ofna 9.5 Pro 150cc fuel tank with Ofna #30287 fuel tank posts, battery box deleted

-4907 T Maxx receiver box with Traxxas #3034 On/Off switch and charging jack installed

-RPM shock towers and body mounts

-RPM 3.3 Maxx A arms

-Lunsford Racing titanium hinge pins

-Stock 3.3 Maxx Axle carriers with all new bearings

-Stock 3.3 Maxx tie rods and ends

-Traxxas #3762 Ultra Shocks with Lunsford #7605 titanium springs and Associated MGT #25065 copper extra firm springs, 45 and 50 weight Losi shock oil

-Red shock covers from E bay

-Aluminum 3.3 Maxx steering linkage

-THS Racing #320 3.3 steel CVD's

-Ofna Monster Pirate rims and tires with Ofna 17mm hub adapters

-Ofna #90138 RTR hump pack with wall charger

-Futaba 3PRKA 2.4GHz 3 channel radio

-Savox SW-0231MG waterproof steering servo

-Traxxas 2056 waterproof throttle servo

-Proline #3345-00 F150 Raptor 1/8 scale body

And now some pics of the completed truck Enjoy!

Enjoy!

And for information sake, here are some pics of the diffs.

This is of the 3908 E Maxx diff with the 4909 pinion installed next to the old Pro .15 diff (The dirty one of course). The other pic shows the difference of the pinions themselves.

Here's my shimming method used. It actually worked out quite nicely. The front center shaft is similar, but required one less larger washer for a tight fit.

The only other mods I want to do besides a new steering servo is some better shocks to replace the stock plastic ones, and possibly a dual tank mod. I am considering using an Ofna Pirate tank where the stock one used to be. It is 125cc and perfectly square so it would likely work better than the stock tank does, and fits roughly in the same area. For now I'll see what kind of run times I get on the 150cc 9.5 tank and just enjoy the truck as it is

I still need to trim and paint my body and of course break the new engine in, but I'm waiting on solid warmer weather for those things. As soon as it's 50 degrees or so out for a few days in a row it will be break in time! Once I get the body painted I will post pics of it as well. I also plan on a few vids of the truck running and racing a stock 3.3 T Maxx.

I still need to trim and paint my body and of course break the new engine in, but I'm waiting on solid warmer weather for those things. As soon as it's 50 degrees or so out for a few days in a row it will be break in time! Once I get the body painted I will post pics of it as well. I also plan on a few vids of the truck running and racing a stock 3.3 T Maxx.This was a fun project, and the truck is definitely one of a kind now! I am quite happy with the way it turned out.

Here is the list of all the major parts I used:

-LRP Z.28R Spec 3 pull start

-Motor Saver #151660 1/8 scale air filter

-HPI Savage X flywheel, clutch shoes, and clutch bell (17 tooth)

-THS Racing #825H Savage pipe with Reedy #28047 header

-ACNCM big block Maxx chassis with rear dogbone, center braces, center skid plate, and engine mount, Ofna #30282 engine mount shims

-ACNCM billet bulkheads w/ RPM bulkhead braces

-RC Raven aluminum T Maxx skid plates and bumpers

-New complete 4907 T Maxx tranny with 4909 T Maxx 5mm output shaft and 4909 brakes

-3.3 T Maxx slipper clutch with 40 tooth Revo spur gear

-E Maxx 3908 differentials with 4909 T Maxx pinions

-Ofna 9.5 Pro 150cc fuel tank with Ofna #30287 fuel tank posts, battery box deleted

-4907 T Maxx receiver box with Traxxas #3034 On/Off switch and charging jack installed

-RPM shock towers and body mounts

-RPM 3.3 Maxx A arms

-Lunsford Racing titanium hinge pins

-Stock 3.3 Maxx Axle carriers with all new bearings

-Stock 3.3 Maxx tie rods and ends

-Traxxas #3762 Ultra Shocks with Lunsford #7605 titanium springs and Associated MGT #25065 copper extra firm springs, 45 and 50 weight Losi shock oil

-Red shock covers from E bay

-Aluminum 3.3 Maxx steering linkage

-THS Racing #320 3.3 steel CVD's

-Ofna Monster Pirate rims and tires with Ofna 17mm hub adapters

-Ofna #90138 RTR hump pack with wall charger

-Futaba 3PRKA 2.4GHz 3 channel radio

-Savox SW-0231MG waterproof steering servo

-Traxxas 2056 waterproof throttle servo

-Proline #3345-00 F150 Raptor 1/8 scale body

And now some pics of the completed truck

Enjoy!

Enjoy!And for information sake, here are some pics of the diffs.

This is of the 3908 E Maxx diff with the 4909 pinion installed next to the old Pro .15 diff (The dirty one of course). The other pic shows the difference of the pinions themselves.

Here's my shimming method used. It actually worked out quite nicely. The front center shaft is similar, but required one less larger washer for a tight fit.

Last edited by Maxximize; 04-05-2015 at 08:32 PM.

#39

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

OK, a very small update to the truck here. I finally replaced my old steering servo! I went to the LHS to see what they had in stock, I was going to order a Savox SC-0251 online but I'd rather buy one locally in case there are problems with it. Anyways, no SC-251 in sock, all they had in my desired torque range of 200 plus oz-in was the SC-1256, which is pretty expensive. But after searching a bit more the guy found a waterproof one, the Savox SW-0231. It cost $45 and has 208 oz-in of torque @ 6v and all metal gears, not too bad for a waterproof servo at that price. Well I bought it and installed it onto the truck. Initial impression of it is good, no jittery twitching and sounds good. It also has a very solid feel to the case and came with 2 different sets of 4 screws to mount it as well as some servo horns. It is a bit taller than my Cirrus or my Traxxas 2056 is and heavier than both. It is actually able to turn my huge and very heavy tires while the truck is sitting still, which surprised me. There is a noticeable difference in power and speed from the Cirrus CDS 751 I was using, which is rated at 180 oz-in of torque @ 6v. Anyways I plan on running my truck later this week finally, which I have yet to really do due to the continiued bad weather in the north here. We are hoping to get a few trucks out toward the end of the week and into the weekend. We will have 2 3.3 T Maxx's, one with an O.S. .21TM and one with a stock 3.3, my T Maxx, and a Pro .15 Nitro Rusty. We will be capturing some videos of the trucks including mine, though it will be slow running because I'm still breaking it in. After that I plan on doing some short reviews on some of the aftermarket parts I have installed. A few other videos will be taken of the truck once it's broken in to compare it to the other T Maxx's and probably posted here as well. I also made some progress on the body, did the major rough trimming with my body scissors. Now I just need to smooth out the edges with my Dremel and lay the paint on it! Of course, pics of the body will be posted when it's done. Stay tuned, guys. More stuff to come here yet

Last edited by Maxximize; 04-05-2015 at 08:34 PM.

#40

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Got to run the truck for a few hours this weekend! I'm very happy with how it ran. It was hard to start for the first 2 tanks, but after that it got easier. On tank # 6 of break in, I leaned out the low and high end just a tad more than I had to to get it to run. It's still running quite rich, but fires up in 1 or 2 pulls now and runs great! I will now lean it a bit after every tank until it is slightly rich from max performance. No videos yet, sadly nobody brought a suitable recorder to the park on run day, hopefully we will have a few next time. Anyways, time for a few reviews on some important parts.

Engine: So far so good, it is very receptive to tuning and runs very cool. Even with a sock double wrapped on the head it took awhile to hit running temp on a 60 degree day. I used Byron's 25% Gen 2 Worlds Blend with 8% oil, and added about .5 oz. of pure castor oil for about 10% total oil. The engine ran well on this, so I think 25% - 30% with 10% or 11% oil would be perfect for it. I'm going to try Bones Brew 30/10 in it next.

For a sub $200 engine, this thing is amazing! Even though I only ran it at 1/2 throttle or less so far, I can tell it has a lot of power. It was constantly trying to hit 2nd gear and was actually keeping up with the 3.3 Maxx trucks that were running 3/4 to full throttle. The power difference is almost inconceivable. It is quite fuel hungry though. I'm running it very rich, but even with low throttle runs it's killing a 150cc tank in about 10 minutes. In comparison my buddies Savage X 4.6 took 15 to 20 minutes to drain it's tank during it's break in. Overall, this is a great engine so far. I would feel safe recommending it to anybody looking for a good replacement budget big block.

Steering servo: This I was a bit apprehensive about initially. I replaced my old servo (CDS-751) with a Savox SW-0231. It has all metal gears and is water proof. The torque specs are about 200 oz. in. @ 6 volts, and increase of roughly 20 oz. in. over the old servo. I was not sure the torque would be enough for my truck's immense weight and large, heavy tires as the old on struggled with it before. Well, I was wrong. For a $45 servo this thing is really impressive. It has plenty of speed and torque to pull the truck through fast, tight corners and is very responsive. It makes no noise and doesn't jitter when it's at zero position. It also appears to use little to no more juice than my old one did. I'd recommend this to those looking for a solid budget servo for any 1/8 scale monster truck or smaller. It would make a great upgrade for a T Maxx of any form. If it can steer my truck, it will steer any truck My truck is closing in on 15 lb. in RTR form now by the way, so it is a great test vehicle for servos, especially with the tires I'm running.

My truck is closing in on 15 lb. in RTR form now by the way, so it is a great test vehicle for servos, especially with the tires I'm running.

Radio: Another budget part, the Futaba 3PRKA. This is a rtr style radio with 3 channels. At $60, the price is great for those looking to replace an aging radio. I did just that, replacing an old Traxxas TQ 27 MHz 3 channel radio. This weekend I ran my truck with 3 other 2.4 GHz equipped trucks, 2 Traxxas TQ radios and a Spektrum DX 4S, and it worked perfectly. I even tested it's durability accidentally. I dropped it from the floor of my brother's lifted Dodge Ram as I got out, it hit the concrete, and nothing broke Still works perfectly well. Range was good, I got roughly 200 yards away before turning back with no cut outs. It is easy on batteries, too. Highly recommended as a solid replacement for a less than desirable or outdated RTR radio. This is my first 2.4 GHz radio, and man am I glad I switched! No more crystals to carry around, no worries about interference. Great radio for the price.

Still works perfectly well. Range was good, I got roughly 200 yards away before turning back with no cut outs. It is easy on batteries, too. Highly recommended as a solid replacement for a less than desirable or outdated RTR radio. This is my first 2.4 GHz radio, and man am I glad I switched! No more crystals to carry around, no worries about interference. Great radio for the price.

And lastly, the Ofna fuel tank mod: I've seen this debated before on quite a few forums. Some will say that there is no need to replace the stock fuel tank on a T Maxx, other say the Ofna fuel tank mod is a must. Well, in my opinion it is not a must, but it is highly recommended. Not only does the tank hold more fuel, but it is designed much better. No fuel can leak through the pressure line, it mounts on posts so it can't crack from chassis flex, and it has a fuel filter stone built into it. The pressure line fitting can rotate 360 degrees, and the cap can be mounted to open to the front or rear of the tank and seals better. And most importantly, it eliminates the half tank lean effect the stock tank creates. This weekend, we ran 2 3.3 T Maxx's, one bone stock, and one using a THS pipe. Both trucks experienced bad half tank leaning, and as I tuned my brother's truck I remembered how much of a pain it is to tune for optimal power with that tank. The Savage we ran also leaned at half tank, but to a lesser extent. I have dealt with that for years with my T Maxx, and used several tanks designed like the stock one. They all lean out at half tank. The Ofna tank does not lean out at all. My truck ran the same from full to bone dry. This is a great mod, I recommend this to all T Maxx owners. The only downside is you lose your stock battery box and have to drill a hole in the chassis, so the convenience of using AA's for your receiver is gone with this mod. I bought a cheap Ofna NiCD hump pack and mounted it next to the steering servo. It has ran a full quart of fuel since Friday and still has charge left in it. I topped it off for a few hours on Saturday morning before going to the park, but that was not a full recharge and it was not dead when I did that. Great battery pack for the money.

Before I forget, another thing I see pop up on forums regarding T Maxx A arms and hinge pins. The stock pins and the Traxxas titanium pins are usually too short for RPM arms in combination with aftermarket bulkheads. I went the Lunsford route, and these fit perfectly. They do cost more, though. Not shaving the arms down for a proper fit is worth it I'd say. If upgrading to the RPM arms, I recommend the Lunsford hinge pins. My bother bought the Traxxas ones for his Maxx using RPM bulks and arms and had to sand the arms down to make the pins fit even without aluminum bulks.

Well, those are the important parts I wanted to review, hopefully others will find this helpful in the future. Apologies for the wall of text, but I like to be thorough Any questions about any other parts or mods I did to this truck are more than welcome. There are quite a few parts and mods on it that cross between all versions of the T Maxx, not just big block ones.

Any questions about any other parts or mods I did to this truck are more than welcome. There are quite a few parts and mods on it that cross between all versions of the T Maxx, not just big block ones.

Finished the body up today, I'm pretty happy with it considering it's my first body painted and trimmed in about 12 years. It's a really nice body, and thick too. Proline makes the best by far!

Engine: So far so good, it is very receptive to tuning and runs very cool. Even with a sock double wrapped on the head it took awhile to hit running temp on a 60 degree day. I used Byron's 25% Gen 2 Worlds Blend with 8% oil, and added about .5 oz. of pure castor oil for about 10% total oil. The engine ran well on this, so I think 25% - 30% with 10% or 11% oil would be perfect for it. I'm going to try Bones Brew 30/10 in it next.

For a sub $200 engine, this thing is amazing! Even though I only ran it at 1/2 throttle or less so far, I can tell it has a lot of power. It was constantly trying to hit 2nd gear and was actually keeping up with the 3.3 Maxx trucks that were running 3/4 to full throttle. The power difference is almost inconceivable. It is quite fuel hungry though. I'm running it very rich, but even with low throttle runs it's killing a 150cc tank in about 10 minutes. In comparison my buddies Savage X 4.6 took 15 to 20 minutes to drain it's tank during it's break in. Overall, this is a great engine so far. I would feel safe recommending it to anybody looking for a good replacement budget big block.

Steering servo: This I was a bit apprehensive about initially. I replaced my old servo (CDS-751) with a Savox SW-0231. It has all metal gears and is water proof. The torque specs are about 200 oz. in. @ 6 volts, and increase of roughly 20 oz. in. over the old servo. I was not sure the torque would be enough for my truck's immense weight and large, heavy tires as the old on struggled with it before. Well, I was wrong. For a $45 servo this thing is really impressive. It has plenty of speed and torque to pull the truck through fast, tight corners and is very responsive. It makes no noise and doesn't jitter when it's at zero position. It also appears to use little to no more juice than my old one did. I'd recommend this to those looking for a solid budget servo for any 1/8 scale monster truck or smaller. It would make a great upgrade for a T Maxx of any form. If it can steer my truck, it will steer any truck

My truck is closing in on 15 lb. in RTR form now by the way, so it is a great test vehicle for servos, especially with the tires I'm running.

My truck is closing in on 15 lb. in RTR form now by the way, so it is a great test vehicle for servos, especially with the tires I'm running.Radio: Another budget part, the Futaba 3PRKA. This is a rtr style radio with 3 channels. At $60, the price is great for those looking to replace an aging radio. I did just that, replacing an old Traxxas TQ 27 MHz 3 channel radio. This weekend I ran my truck with 3 other 2.4 GHz equipped trucks, 2 Traxxas TQ radios and a Spektrum DX 4S, and it worked perfectly. I even tested it's durability accidentally. I dropped it from the floor of my brother's lifted Dodge Ram as I got out, it hit the concrete, and nothing broke

Still works perfectly well. Range was good, I got roughly 200 yards away before turning back with no cut outs. It is easy on batteries, too. Highly recommended as a solid replacement for a less than desirable or outdated RTR radio. This is my first 2.4 GHz radio, and man am I glad I switched! No more crystals to carry around, no worries about interference. Great radio for the price.

Still works perfectly well. Range was good, I got roughly 200 yards away before turning back with no cut outs. It is easy on batteries, too. Highly recommended as a solid replacement for a less than desirable or outdated RTR radio. This is my first 2.4 GHz radio, and man am I glad I switched! No more crystals to carry around, no worries about interference. Great radio for the price.And lastly, the Ofna fuel tank mod: I've seen this debated before on quite a few forums. Some will say that there is no need to replace the stock fuel tank on a T Maxx, other say the Ofna fuel tank mod is a must. Well, in my opinion it is not a must, but it is highly recommended. Not only does the tank hold more fuel, but it is designed much better. No fuel can leak through the pressure line, it mounts on posts so it can't crack from chassis flex, and it has a fuel filter stone built into it. The pressure line fitting can rotate 360 degrees, and the cap can be mounted to open to the front or rear of the tank and seals better. And most importantly, it eliminates the half tank lean effect the stock tank creates. This weekend, we ran 2 3.3 T Maxx's, one bone stock, and one using a THS pipe. Both trucks experienced bad half tank leaning, and as I tuned my brother's truck I remembered how much of a pain it is to tune for optimal power with that tank. The Savage we ran also leaned at half tank, but to a lesser extent. I have dealt with that for years with my T Maxx, and used several tanks designed like the stock one. They all lean out at half tank. The Ofna tank does not lean out at all. My truck ran the same from full to bone dry. This is a great mod, I recommend this to all T Maxx owners. The only downside is you lose your stock battery box and have to drill a hole in the chassis, so the convenience of using AA's for your receiver is gone with this mod. I bought a cheap Ofna NiCD hump pack and mounted it next to the steering servo. It has ran a full quart of fuel since Friday and still has charge left in it. I topped it off for a few hours on Saturday morning before going to the park, but that was not a full recharge and it was not dead when I did that. Great battery pack for the money.

Before I forget, another thing I see pop up on forums regarding T Maxx A arms and hinge pins. The stock pins and the Traxxas titanium pins are usually too short for RPM arms in combination with aftermarket bulkheads. I went the Lunsford route, and these fit perfectly. They do cost more, though. Not shaving the arms down for a proper fit is worth it I'd say. If upgrading to the RPM arms, I recommend the Lunsford hinge pins. My bother bought the Traxxas ones for his Maxx using RPM bulks and arms and had to sand the arms down to make the pins fit even without aluminum bulks.

Well, those are the important parts I wanted to review, hopefully others will find this helpful in the future. Apologies for the wall of text, but I like to be thorough

Any questions about any other parts or mods I did to this truck are more than welcome. There are quite a few parts and mods on it that cross between all versions of the T Maxx, not just big block ones.

Any questions about any other parts or mods I did to this truck are more than welcome. There are quite a few parts and mods on it that cross between all versions of the T Maxx, not just big block ones.Finished the body up today, I'm pretty happy with it considering it's my first body painted and trimmed in about 12 years. It's a really nice body, and thick too. Proline makes the best by far!

#43

Senior Member

Thread Starter

Join Date: Sep 2009

Location: menasha, WI

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

Thanks a lot guys! Glad you like it too I am extremely proud of this thing, first high end build I've ever done. And the upside, only one part broke so far, and that was just the center front plastic shaft that snapped on a roll over. I have a bag full of the stock knuckles so I'll be good for awhile there. Looks like I'll be adding a steel CVD there eventually, too hahaha.

I am extremely proud of this thing, first high end build I've ever done. And the upside, only one part broke so far, and that was just the center front plastic shaft that snapped on a roll over. I have a bag full of the stock knuckles so I'll be good for awhile there. Looks like I'll be adding a steel CVD there eventually, too hahaha.

I am extremely proud of this thing, first high end build I've ever done. And the upside, only one part broke so far, and that was just the center front plastic shaft that snapped on a roll over. I have a bag full of the stock knuckles so I'll be good for awhile there. Looks like I'll be adding a steel CVD there eventually, too hahaha.

I am extremely proud of this thing, first high end build I've ever done. And the upside, only one part broke so far, and that was just the center front plastic shaft that snapped on a roll over. I have a bag full of the stock knuckles so I'll be good for awhile there. Looks like I'll be adding a steel CVD there eventually, too hahaha.