Induction Timing

#26

Junior Member

Join Date: Apr 2007

Location: wolves, UNITED KINGDOM

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

I am a noob to modding rc engines but i am a mechanic by trade so i understand the importance of correct engine timing.I want to mod my vx.18. ive red how to port and polish and to give the crank a fang. but how do you know how much material to remove from the top of the sleve ports .it has been said to know this before removing any material.

So my question is how much material can you remove from the sleve windows and induction window on the crank for best performance or where can i find this info from.thnx once again very good reading.

So my question is how much material can you remove from the sleve windows and induction window on the crank for best performance or where can i find this info from.thnx once again very good reading.

#27

Senior Member

Join Date: Apr 2005

Location: Charlottesville,

VA

Posts: 5,253

Likes: 0

Received 0 Likes

on

0 Posts

Trial and error basically. Modding port timings changes the caracteristic of the power band so it all depends on what you like to do.

I bought a software called MOTA. It's 2 stroke engine simulator and I've learned a lot from just changing port configurations and port sizes. It gives you a feel for it and will clue you in on what to do.

Google MOTA engine simulation and you should find it fairly easy. It's around $185 or so IIRC.

I bought a software called MOTA. It's 2 stroke engine simulator and I've learned a lot from just changing port configurations and port sizes. It gives you a feel for it and will clue you in on what to do.

Google MOTA engine simulation and you should find it fairly easy. It's around $185 or so IIRC.

#29

Senior Member

Join Date: Apr 2005

Location: Charlottesville,

VA

Posts: 5,253

Likes: 0

Received 0 Likes

on

0 Posts

It's awesome and WELL worth the money. Playing around with it gives you a good feel.

I entered all parameters for the OS RG and measured the OS-T2050 pipe and ran a simulation. It returned a max hp of just below 2hp close to the rpm stated by OS. Pretty damn good I must say since OS says it should have 1.9hp.

I entered all parameters for the OS RG and measured the OS-T2050 pipe and ran a simulation. It returned a max hp of just below 2hp close to the rpm stated by OS. Pretty damn good I must say since OS says it should have 1.9hp.

#31

Join Date: Jan 2007

Location: Palm Coast, FL

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Sounds like your theory is sound because math is not only possible but it is the true means of which engineers use. Good job Jim, I sent this to a person who mods engines and asked him to take a look, I wont drop any names but I hope he post something here. It will be a treat for all![>:]

#32

Senior Member

Good luck finding a modder who actualy alters sleeve port timing..... at the very most the odd modifier may alter exhaust timing, but i know of none who will hand cut transfer and boost timings........ Myself As a hobby i alter the timing on all my modded motors, the only drawback is i create motors sometimes too powerful to even be usefull....

#33

Senior Member

Thread Starter

Join Date: Jul 2005

Location: Torchy the Fiery Fast RC Turtl

Posts: 10,544

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: FastRcCars

Sounds like your theory is sound because math is not only possible but it is the true means of which engineers use. Good job Jim, I sent this to a person who mods engines and asked him to take a look, I wont drop any names but I hope he post something here. It will be a treat for all![>:]

Sounds like your theory is sound because math is not only possible but it is the true means of which engineers use. Good job Jim, I sent this to a person who mods engines and asked him to take a look, I wont drop any names but I hope he post something here. It will be a treat for all![>:]

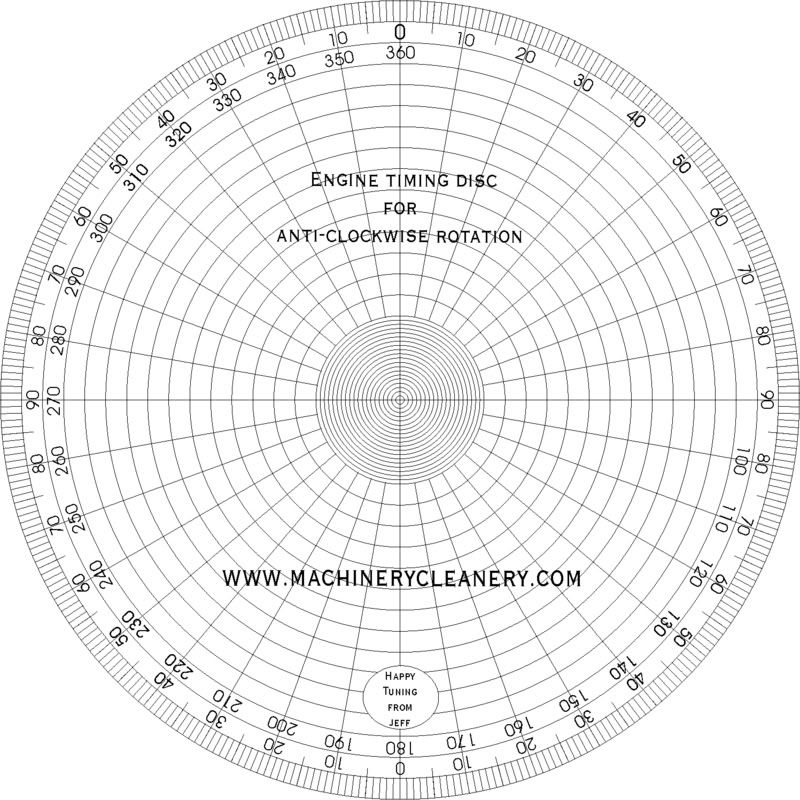

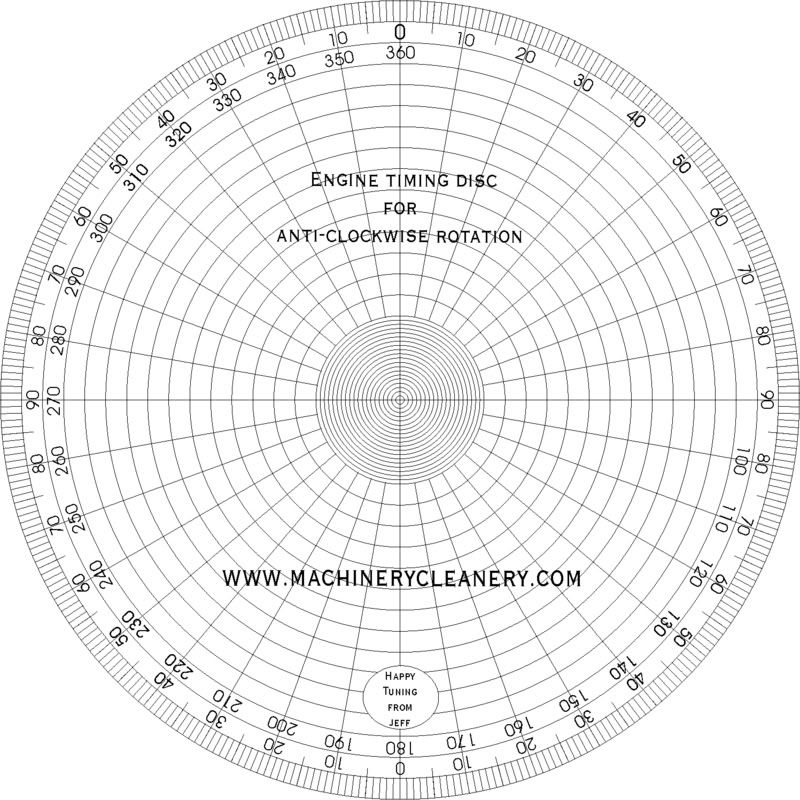

Supertib is right: altering the timing profile to advance them is difficult. I use masking tape on the inside of the sleeve to mark how high I want to cut up, but just getting the masking tape into proper position is quite a chore in itself. What I have resorted to is oputting the masking tape just a little lower tghan I know where the cut goal is, then, with the sleeve and piston installed, I turn the degree wheel to the exact degree I want the port to open. The piston pushes up the tape to the exact lin to where the port needs to be cut up to.

I hope that little helps modders and amatuers alike in making how high in the sleeve to cut up.

#35

Senior Member

Join Date: Dec 2006

Location: Saudi, SAUDI ARABIA

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Tubbed440

Lots of good info here. Keep it coming fellas.....I'm absorbing as fast as I can.

Lots of good info here. Keep it coming fellas.....I'm absorbing as fast as I can.

Induction Timing eh? :lol: <--

Induction Timing eh? :lol: <--

#36

Senior Member

Join Date: Jun 2007

Location: Fort Worth, TX

Posts: 251

Likes: 0

Received 0 Likes

on

0 Posts

Once you have crank position locked for your new timing marks measure depth from top of sleeve to top of piston. Next, transfer the inside measurement to the outside of the sleeve, mark with scribe, and start cutting!

For crank induction, remove the carb, turn crank to new open/close timing and scribe a line on the crank. Remove crank, cut, polish edges, reassemble, and go run!

Works for me!

For crank induction, remove the carb, turn crank to new open/close timing and scribe a line on the crank. Remove crank, cut, polish edges, reassemble, and go run!

Works for me!

#37

Senior Member

Join Date: Feb 2007

Location: Somerset, UNITED KINGDOM

Posts: 2,324

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: lsurber

Once you have crank position locked for your new timing marks measure depth from top of sleeve to top of piston. Next, transfer the inside measurement to the outside of the sleeve, mark with scribe, and start cutting!

Once you have crank position locked for your new timing marks measure depth from top of sleeve to top of piston. Next, transfer the inside measurement to the outside of the sleeve, mark with scribe, and start cutting!

I think the method that SavageJim has posted above(edge tape up cylinder with piston using d.wheel)is an excellent method,just ensure the sleeve is totally grease free and press the tape down firmly so it wont move then re-check

ORIGINAL: lsurber

For crank induction, remove the carb, turn crank to new open/close timing and scribe a line on the crank. Remove crank, cut, polish edges, reassemble, and go run!

Works for me!

For crank induction, remove the carb, turn crank to new open/close timing and scribe a line on the crank. Remove crank, cut, polish edges, reassemble, and go run!

Works for me!

I agree can't go wrong with that

I agree can't go wrong with that

#38

Senior Member

Join Date: Jun 2007

Location: Fort Worth, TX

Posts: 251

Likes: 0

Received 0 Likes

on

0 Posts

If you measure the incidence angle of the port and sleeve wall thickness then use the law of sines you can determine where to transcribe the line!

SinA/a = SinB/b =SinC/c

Note: A and B will complement each other so you only need to find one and you know the other!

C=90 degrees

Sorry, sometimes I assume too much!

It's also easier for me to cut referencing the outside rather than the inside of the sleeve![8D]

Personally, I just make a good guess!!!!!!! LOL!!!! Tape inside is also an excellent idea to avoid flaking the plate! If you do make timing changes to ports you may end up with a paperweight if the plating comes off!!!!! ]

]

Lee

SinA/a = SinB/b =SinC/c

Note: A and B will complement each other so you only need to find one and you know the other!

C=90 degrees

Sorry, sometimes I assume too much!

It's also easier for me to cut referencing the outside rather than the inside of the sleeve![8D]

Personally, I just make a good guess!!!!!!! LOL!!!!

Tape inside is also an excellent idea to avoid flaking the plate! If you do make timing changes to ports you may end up with a paperweight if the plating comes off!!!!! ]

]Lee

#39

Senior Member

Join Date: Feb 2007

Location: Somerset, UNITED KINGDOM

Posts: 2,324

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: lsurber

If you measure the incidence angle of the port and sleeve wall thickness then use the law of sines you can determine where to transcribe the line!

Sorry, sometimes I assume too much!

It's also easier for me to cut referencing the outside rather than the inside of the sleeve![8D]

If you measure the incidence angle of the port and sleeve wall thickness then use the law of sines you can determine where to transcribe the line!

Sorry, sometimes I assume too much!

It's also easier for me to cut referencing the outside rather than the inside of the sleeve![8D]

#41

Join Date: Jan 2007

Location: Palm Coast, FL

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Jim, I think this is a good tip but there is no way to match a cnc machine and some one who has been a Machinist for 25 years, cnc programmer, and has a Fluid dynamics engineering degree. I do not know why he has not posted here yet; (other than being busy workin on the big boys toys.) Here is a pic That looks cool and shows the difference between cnc modding and the good old fashiond hand job! Do not get me wrong I have been doing HiPro work on hot rods for years and it takes a combination. IE: machines to punch out the head to desired specs, then by hand to finish the porting and polishing.

The main thing everyone should know is "be very careful when opening crank window and after porting the rest you will need to rebalance! Many trics to this But one hand method I have seen that does work will require a little fabbing. First make a jig that will hold the crank with the bearings on it and will fit on an ultrasonic. (small machine that cleans jewelry and such.) make sure bearings are very easy to turn (new and well oiled) straps will wrap arround bearings (also make sure you have clearance ie: crank will not touch anything other than inner race of bearings.) and as the ultrasonic vibs rotate crank in 45 and 90 degree increments. Watch the crank after each reposition and the heavy part will rotate to the bottom after a few seconds or so, after it stops mark heavy part on crank on the counter ballance weight (big part all arround where rod connects). Grind a LITTLE off heavy side at a time rechecking often, When you can put the crank in any position and it does not move its Balanced!

Remember bearings do have resistance so this is not perfect but it will work and if you want to get technical and be a big time perfecto after the crank is done, balance the drive washer and flywheel. Simply put them on the crank (1 at a time) and do the same as before only drill small hole in the side of drive washer to remove weight and for the flywheel... Well it depends on the wheel I am sure you can find a way to lighten the heavy side. FastRcCars [>:]

The main thing everyone should know is "be very careful when opening crank window and after porting the rest you will need to rebalance! Many trics to this But one hand method I have seen that does work will require a little fabbing. First make a jig that will hold the crank with the bearings on it and will fit on an ultrasonic. (small machine that cleans jewelry and such.) make sure bearings are very easy to turn (new and well oiled) straps will wrap arround bearings (also make sure you have clearance ie: crank will not touch anything other than inner race of bearings.) and as the ultrasonic vibs rotate crank in 45 and 90 degree increments. Watch the crank after each reposition and the heavy part will rotate to the bottom after a few seconds or so, after it stops mark heavy part on crank on the counter ballance weight (big part all arround where rod connects). Grind a LITTLE off heavy side at a time rechecking often, When you can put the crank in any position and it does not move its Balanced!

Remember bearings do have resistance so this is not perfect but it will work and if you want to get technical and be a big time perfecto after the crank is done, balance the drive washer and flywheel. Simply put them on the crank (1 at a time) and do the same as before only drill small hole in the side of drive washer to remove weight and for the flywheel... Well it depends on the wheel I am sure you can find a way to lighten the heavy side. FastRcCars [>:]

#42

Senior Member

Thread Starter

Join Date: Jul 2005

Location: Torchy the Fiery Fast RC Turtl

Posts: 10,544

Likes: 0

Received 0 Likes

on

0 Posts

If you are referring to MXWrench (Brian Kinney), I too am wondering why he has not posted vey much at all. I have asked him to post calculations and other engineeing concepts on another site, but he never has replied. I too would love to here his input on my indution timing thread and particularly, how to factor in the fluid flow calculations into an increased induction duration.

#43

Senior Member

ORIGINAL: FastRcCars

Jim, I think this is a good tip but there is no way to match a cnc machine and some one who has been a Machinist for 25 years, cnc programmer, and has a Fluid dynamics engineering degree. I do not know why he has not posted here yet; (other than being busy workin on the big boys toys.) Here is a pic That looks cool and shows the difference between cnc modding and the good old fashiond hand job! Do not get me wrong I have been doing HiPro work on hot rods for years and it takes a combination. IE: machines to punch out the head to desired specs, then by hand to finish the porting and polishing.

The main thing everyone should know is "be very careful when opening crank window and after porting the rest you will need to rebalance! Many trics to this But one hand method I have seen that does work will require a little fabbing. First make a jig that will hold the crank with the bearings on it and will fit on an ultrasonic. (small machine that cleans jewelry and such.) make sure bearings are very easy to turn (new and well oiled) straps will wrap arround bearings (also make sure you have clearance ie: crank will not touch anything other than inner race of bearings.) and as the ultrasonic vibs rotate crank in 45 and 90 degree increments. Watch the crank after each reposition and the heavy part will rotate to the bottom after a few seconds or so, after it stops mark heavy part on crank on the counter ballance weight (big part all arround where rod connects). Grind a LITTLE off heavy side at a time rechecking often, When you can put the crank in any position and it does not move its Balanced!

Remember bearings do have resistance so this is not perfect but it will work and if you want to get technical and be a big time perfecto after the crank is done, balance the drive washer and flywheel. Simply put them on the crank (1 at a time) and do the same as before only drill small hole in the side of drive washer to remove weight and for the flywheel... Well it depends on the wheel I am sure you can find a way to lighten the heavy side. FastRcCars [>:]

Jim, I think this is a good tip but there is no way to match a cnc machine and some one who has been a Machinist for 25 years, cnc programmer, and has a Fluid dynamics engineering degree. I do not know why he has not posted here yet; (other than being busy workin on the big boys toys.) Here is a pic That looks cool and shows the difference between cnc modding and the good old fashiond hand job! Do not get me wrong I have been doing HiPro work on hot rods for years and it takes a combination. IE: machines to punch out the head to desired specs, then by hand to finish the porting and polishing.

The main thing everyone should know is "be very careful when opening crank window and after porting the rest you will need to rebalance! Many trics to this But one hand method I have seen that does work will require a little fabbing. First make a jig that will hold the crank with the bearings on it and will fit on an ultrasonic. (small machine that cleans jewelry and such.) make sure bearings are very easy to turn (new and well oiled) straps will wrap arround bearings (also make sure you have clearance ie: crank will not touch anything other than inner race of bearings.) and as the ultrasonic vibs rotate crank in 45 and 90 degree increments. Watch the crank after each reposition and the heavy part will rotate to the bottom after a few seconds or so, after it stops mark heavy part on crank on the counter ballance weight (big part all arround where rod connects). Grind a LITTLE off heavy side at a time rechecking often, When you can put the crank in any position and it does not move its Balanced!

Remember bearings do have resistance so this is not perfect but it will work and if you want to get technical and be a big time perfecto after the crank is done, balance the drive washer and flywheel. Simply put them on the crank (1 at a time) and do the same as before only drill small hole in the side of drive washer to remove weight and for the flywheel... Well it depends on the wheel I am sure you can find a way to lighten the heavy side. FastRcCars [>:]

you cannot static balance one of these motors..... the only way to balance these motors is to use a harmonic balancing jig, that spins the crank with bob weights up to operating RPM and measures the harmonics of the engine. You can use the same equipment used to balance turbines such as a Chadwick/Honywell Vibrex 2000 .. You cannot balance a single cylinder engine as is being described here, your info is completely wrong and can cause people more harm then good. I am sorry to say that and I mean no insult but ..you can only balance one of these engines to a specific RPM, as well the more you lighten the crank the lower the RPM the motor will encounter bad harmonics....usualy to balance one of these to higher RPM's it would require the adition of weight to the crank, not a reduction...... as well depending on what RPM you balance the motor to the positon of the weight will change...

#44

Join Date: Jan 2007

Location: Palm Coast, FL

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Lets face it it might help if you read before you post. I said it should be done with machines but if you have already done some heavy grinding by hand chances are you have really thrown off the ballance. (common sence) so if you are doing it by hand the best way I know of is to do what I stated in my previous post. Now for not working on a single cylinder engine, This process is used in motorcycle shops and most PWC manufactures train techs on using a V block jig (polaris, seadoo, tigershark...) This jig is also used on both two stroke and four stroke dirt bike engines (Honda, suzuki, Kaw...) when the customer is complaining of harmonic vibration from engine, After ruling out the obvious tuning etc. The factory will have the tech do a tear down and check the crank this way, I know as I have done it many times, But the first time I seen it used on a nitro engine was when a tech I worked with used it on his nitro engine that he was modding by Hand and he was using an ultrasonic with a flat tray. (made for a bowl / cleaning fluid) He did this because the factory techs sometimes would have us tap the side of the bench with a hammer to cause vibrations to see if crank would move. I do under stand that these engines are turning a much higher Rpm but to take something way out of Ballance and leave it alone is worse than to get it pretty close. I hope you would agree on that. My personal Opinion is that it is worth $80.00 to $125.00 to have it professionally modded, but that is not what this thread is about. It is about using math to mod and doing it by hand and people do it every day!

I mean you no disrespect but look at the picture. No weight was added to this crank and it is turning a much higher rpm, infact you can clearly see it was lightened very much. FastRcCars[>:]

I mean you no disrespect but look at the picture. No weight was added to this crank and it is turning a much higher rpm, infact you can clearly see it was lightened very much. FastRcCars[>:]

#45

Join Date: Jan 2007

Location: Palm Coast, FL

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

No Jim I am not and I am not a name dropper but I also do not want to be mr mystery, so I will say that his engines and Mods power the fastest RC drag car in the World , Melvin Alston IMDRA Extreme class. This is an actual Quote from an email he sent me "I was flown to Italy by Mario Rossi of Novarossi engines to consult him on new engine development, Mario and I are good friends now , and he sends me engines every month for Mods."

Me, My name is nobody in this world but I am highly trained and experienced for all sorts of engines. My true calling is Hotrods and I can say that in the mid 80's to the late 90's I was well known and had customers from all over the world. Many of the cars I did ended up in one mag or another, But in the late 90's I moved to the moutains and I did not own property, there were no shops to rent so to work at a cycle shop I went. It was a lot of fun and for 5 years I got to take home water craft to test because I lived on the lake. (alot of time it was to make sure the vibration was gone.) Jim I can tell you I have met many engineers for one thing or another and even in design and as I said before math is how its done. I think this is a good post and your theory seems right on but I would like to see what Erik thinks after all he's the man. One thing, the diagram you have that shows where to grind the sides of the crank window could be misleading to a noob. I know it is an example to show where the changes will be after preforming the calculations, but some might look at the pic and start grinding away... but all in all as I said before it is real good for someone to get this far with out working in the biz. (in and around mod shops) Thanks, FastRcCars[>:]

Me, My name is nobody in this world but I am highly trained and experienced for all sorts of engines. My true calling is Hotrods and I can say that in the mid 80's to the late 90's I was well known and had customers from all over the world. Many of the cars I did ended up in one mag or another, But in the late 90's I moved to the moutains and I did not own property, there were no shops to rent so to work at a cycle shop I went. It was a lot of fun and for 5 years I got to take home water craft to test because I lived on the lake. (alot of time it was to make sure the vibration was gone.) Jim I can tell you I have met many engineers for one thing or another and even in design and as I said before math is how its done. I think this is a good post and your theory seems right on but I would like to see what Erik thinks after all he's the man. One thing, the diagram you have that shows where to grind the sides of the crank window could be misleading to a noob. I know it is an example to show where the changes will be after preforming the calculations, but some might look at the pic and start grinding away... but all in all as I said before it is real good for someone to get this far with out working in the biz. (in and around mod shops) Thanks, FastRcCars[>:]

#46

If you want the maths for balancing a single cylinder engine then go to http://home.planet.nl/~wakke007/fmv/fmv_3.htm section 3.5 Balancing. Basically the best compromise is reached when the crank counterweight balances the crankpin side plus the weight of the piston/gudgeon pin and half the weight of the rod. This is usually done in a static balancer with an appropriate counterweight slipped over the crankpin. Getting this degree of balance though is extremely difficult. BTW, I like the idea of the ultrasonic vibrations to settle the crank  .

.

.

.

#47

Senior Member

ORIGINAL: FastRcCars

I mean you no disrespect but look at the picture. No weight was added to this crank and it is turning a much higher rpm, infact you can clearly see it was lightened very much. FastRcCars[>:]

I mean you no disrespect but look at the picture. No weight was added to this crank and it is turning a much higher rpm, infact you can clearly see it was lightened very much. FastRcCars[>:]

Its no big deal really

..I should have read your post more fully......everything's all fine and dandy in theory, but untill the motor is spun on a proper balancing system we have no idea if the motor was even balanced from factory to begin with ( most are not ) , so attempting to static balance after a heavy modding may end up throwing you out even worse at the target RPM.... As well i do beleive the methods and standards for balancing are much different for a 40 000 Rpm motor and a 10 000 Rpm motor, some of the rules change the higher the RPM the motor climbs... but I not an expert on this, but am currently looking into properly balancing some personal mills over winter as a project.....

..I should have read your post more fully......everything's all fine and dandy in theory, but untill the motor is spun on a proper balancing system we have no idea if the motor was even balanced from factory to begin with ( most are not ) , so attempting to static balance after a heavy modding may end up throwing you out even worse at the target RPM.... As well i do beleive the methods and standards for balancing are much different for a 40 000 Rpm motor and a 10 000 Rpm motor, some of the rules change the higher the RPM the motor climbs... but I not an expert on this, but am currently looking into properly balancing some personal mills over winter as a project..... Interesting story about the engine modder, Mario Rossi knows how to build a great track motor, and if your buddy had a hand in designing the Ninja mills " Hats off to him ! " the MR Ninja mills seriously kick ass on the track........

I dont understand the picture of the modded motor and its relevance to engine balancing.... Is that a motor modded by your buddy ? is it hand done ? sorry to ask, just the internet is hard to convey a proper message at times...

#48

Join Date: Jan 2007

Location: Palm Coast, FL

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Dude its all good, and like I said I do agree with your point as the only proper way to balance a nitro motor is with the proper equipment. To answer your Question the pictures are of mods done with a cnc machine and as far as how he balances his motors, well I will let him answer that , But it has been rebalanced. I would like to point out the Epic EP1800 P an Engine which at one point was on every board on the net, I have a few and stock, the engine specs: 1.8 bhp @39,000 with a max 44,000 rpm (Stock red head). The platinum was the last produced and the specs were all over the place Trin had em for 2.0 bhp @40,0000 and 45,000 rpm max, but towers spec sheet showed 1.9 bhp @ 39,000 and practical rpm: 3,000 to 44,000 and high rpm: 45,000 ???? so who did what where eh? The engine did at least have 1.8 hp at 39,000 rpm and turn up to 44,000 rpm and for $229. and under (I have seen them for 149.) and thats a lot of bang for the buck. I will put two pics here and if you look close you can see where drive washer is drilled (balanced from manufacturer) This is where what I have said to jim over and over about engineers and math, The engines at the conception point are balanced (proto type) but after that it is production and standardization. The factory equipment programmed to make each part like the original (proto) so in theory already balanced, now do they fine tune from there??? I would like to think that there is some form of q.c. that checks the parts prior to assembly but I have never been to any to see for myself. FastRcCars[>:]

#49

Senior Member

Thread Starter

Join Date: Jul 2005

Location: Torchy the Fiery Fast RC Turtl

Posts: 10,544

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: FastRcCars

No Jim I am not and I am not a name dropper but I also do not want to be mr mystery, so I will say that his engines and Mods power the fastest RC drag car in the World , Melvin Alston IMDRA Extreme class. This is an actual Quote from an email he sent me "I was flown to Italy by Mario Rossi of Novarossi engines to consult him on new engine development, Mario and I are good friends now , and he sends me engines every month for Mods."

Me, My name is nobody in this world but I am highly trained and experienced for all sorts of engines. My true calling is Hotrods and I can say that in the mid 80's to the late 90's I was well known and had customers from all over the world. Many of the cars I did ended up in one mag or another, But in the late 90's I moved to the moutains and I did not own property, there were no shops to rent so to work at a cycle shop I went. It was a lot of fun and for 5 years I got to take home water craft to test because I lived on the lake. (alot of time it was to make sure the vibration was gone.) Jim I can tell you I have met many engineers for one thing or another and even in design and as I said before math is how its done. I think this is a good post and your theory seems right on but I would like to see what Erik thinks after all he's the man. One thing, the diagram you have that shows where to grind the sides of the crank window could be misleading to a noob. I know it is an example to show where the changes will be after preforming the calculations, but some might look at the pic and start grinding away... but all in all as I said before it is real good for someone to get this far with out working in the biz. (in and around mod shops) Thanks, FastRcCars[>:]

No Jim I am not and I am not a name dropper but I also do not want to be mr mystery, so I will say that his engines and Mods power the fastest RC drag car in the World , Melvin Alston IMDRA Extreme class. This is an actual Quote from an email he sent me "I was flown to Italy by Mario Rossi of Novarossi engines to consult him on new engine development, Mario and I are good friends now , and he sends me engines every month for Mods."

Me, My name is nobody in this world but I am highly trained and experienced for all sorts of engines. My true calling is Hotrods and I can say that in the mid 80's to the late 90's I was well known and had customers from all over the world. Many of the cars I did ended up in one mag or another, But in the late 90's I moved to the moutains and I did not own property, there were no shops to rent so to work at a cycle shop I went. It was a lot of fun and for 5 years I got to take home water craft to test because I lived on the lake. (alot of time it was to make sure the vibration was gone.) Jim I can tell you I have met many engineers for one thing or another and even in design and as I said before math is how its done. I think this is a good post and your theory seems right on but I would like to see what Erik thinks after all he's the man. One thing, the diagram you have that shows where to grind the sides of the crank window could be misleading to a noob. I know it is an example to show where the changes will be after preforming the calculations, but some might look at the pic and start grinding away... but all in all as I said before it is real good for someone to get this far with out working in the biz. (in and around mod shops) Thanks, FastRcCars[>:]

As it so turns out, I cannot edit my original post anymore; worse yet, some of my original post was cut off. So any addendum I need to do will have to come in the following posts.

As for a CNC machin to mod the engine, I wholeheartedly agree. I would love to have the exacting precision of such machining instead of hands and Dremel bits. Unfortunately, I am a casual RC fan and do not have the money to buy a quality CNC machine. I would love to have one though so I could get into modding, even semi-professionally.

#50

Join Date: Jan 2007

Location: Palm Coast, FL

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Same Here Jim on all! I wish he would post because I am always learning. I also would like his input, and as for the money for the cool equipment... wouldn't we all. heck I would do more mod'n than drive'n. I too do things by hand and have always up till now but I am sending him a couple of my Epics to see what he can crank out of em. I know that up till now he has not offered his services to the public and for me its parking lot bashing with my sleeper! Over time I hope to have him do 6 of my engines, maybe 8 but he has been so busy, he has not emailed me in over a week. I could call his shop but face it I know how it is, when I was at the top of my game I hated the phone. Someone always called at the worst time and when it was a friend and not a customer I would tell them dude I was in the zone... Jim give it some time because last time we talked he said he would give some input, and yes I sent him the link in an email (10-12 days ago??) Thanks FastRcCars[>:]

Supertib, I want you to know I talked to the tech I worked with; on sunday. I am sorry to you and everyone on this board, let me explain. He informed me that when I first seen him using the jig and ultrasonic, he was in fact adding weight to prebalance the crank prior to modding. He said this was a pain to get it right and stated that when he polished the crank (after it was done and the weight removed) it was just as much of a pain trying to remove the epoxy that held on the weight knowing it would throw off the balance a hair. He is anal perfecto, but I wanted you and everyone else to know "MY BAD". I stated in my original post that I have seen this done so I should have called him and got the details prior to post and as I said before this is not the correct way but for us guys that do things by hand, well his engine ran smooth. I have always wanted to try it myself but I have not had a cheapo to practice on. I have always just modded the sleves, did my porting and sealed it up!

I do have one now and I am going to do it myself, I will report back the effects good or bad and edit my post. cool man ?

Supertib, I want you to know I talked to the tech I worked with; on sunday. I am sorry to you and everyone on this board, let me explain. He informed me that when I first seen him using the jig and ultrasonic, he was in fact adding weight to prebalance the crank prior to modding. He said this was a pain to get it right and stated that when he polished the crank (after it was done and the weight removed) it was just as much of a pain trying to remove the epoxy that held on the weight knowing it would throw off the balance a hair. He is anal perfecto, but I wanted you and everyone else to know "MY BAD". I stated in my original post that I have seen this done so I should have called him and got the details prior to post and as I said before this is not the correct way but for us guys that do things by hand, well his engine ran smooth. I have always wanted to try it myself but I have not had a cheapo to practice on. I have always just modded the sleves, did my porting and sealed it up!

I do have one now and I am going to do it myself, I will report back the effects good or bad and edit my post. cool man ?