Jmb t7-a (non-xxl)

#26

Hum, interesting. We're using a Xicoy LGC22 on that same aircraft, landing gear, and stock door servos, and it works fine. I wonder if the LGC15 (which is a more complex controller) is not outputting the servo pulses at the right voltage or pulse repetition rate that the servos respond to.

Do you have another brand of servo that you can plug into the gear door output of the controller and see if it responds to the commands from the controller properly?

Bob

ps, the stock JP controller is basically junk IMHO - I was never able to figure not how to properly adjust it to get the gear and doors sequence correct...

Do you have another brand of servo that you can plug into the gear door output of the controller and see if it responds to the commands from the controller properly?

Bob

ps, the stock JP controller is basically junk IMHO - I was never able to figure not how to properly adjust it to get the gear and doors sequence correct...

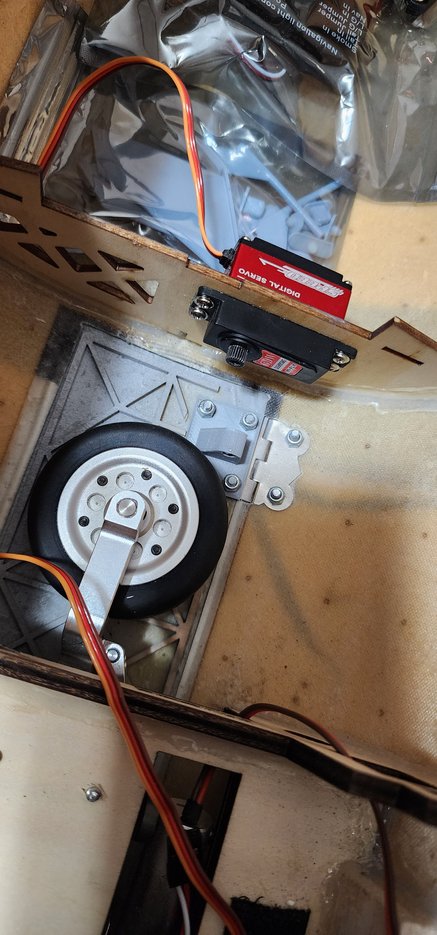

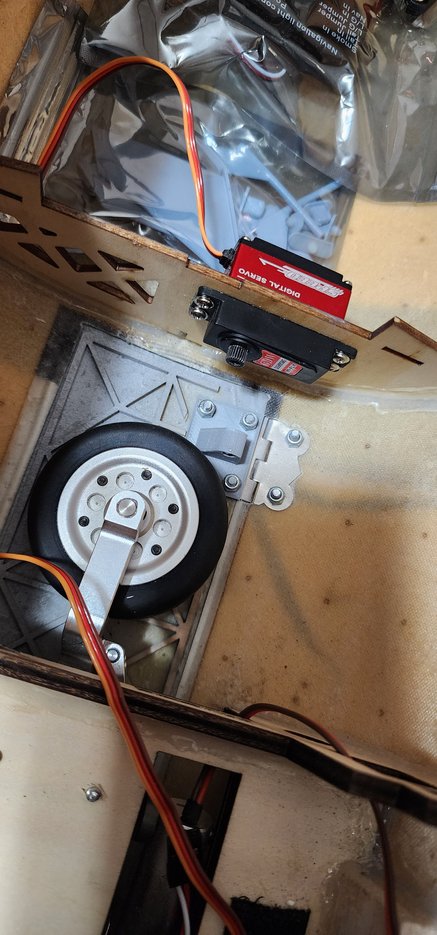

I gave up with the LG15 controller. They just don't move hardly at all with that thing no matter what end points I set. I've plugged the door servo into a regular rx port and it only opens up half way seemingly no matter how i position the servo horn. I've tried setting it to 125% and -125%, and that's ALMOST enough movement but still not quite. I've experimented with adjusting the linkage to be longer and still no luck.

It's almost like it needs to rotate out and back again around a point for it to open all the way (-100% to 100% back to -100% all the in same movement). But I'm no engineer so this is tough. Photos would really help me out with this. I'm wondering if maybe the servo needs turned 180 degrees to move the cog away from the door hinge?

I got the rear doors to work, those were straightforward. Just had to reposition the arms.

Last edited by RadialWacko; 08-30-2024 at 03:04 PM.

#27

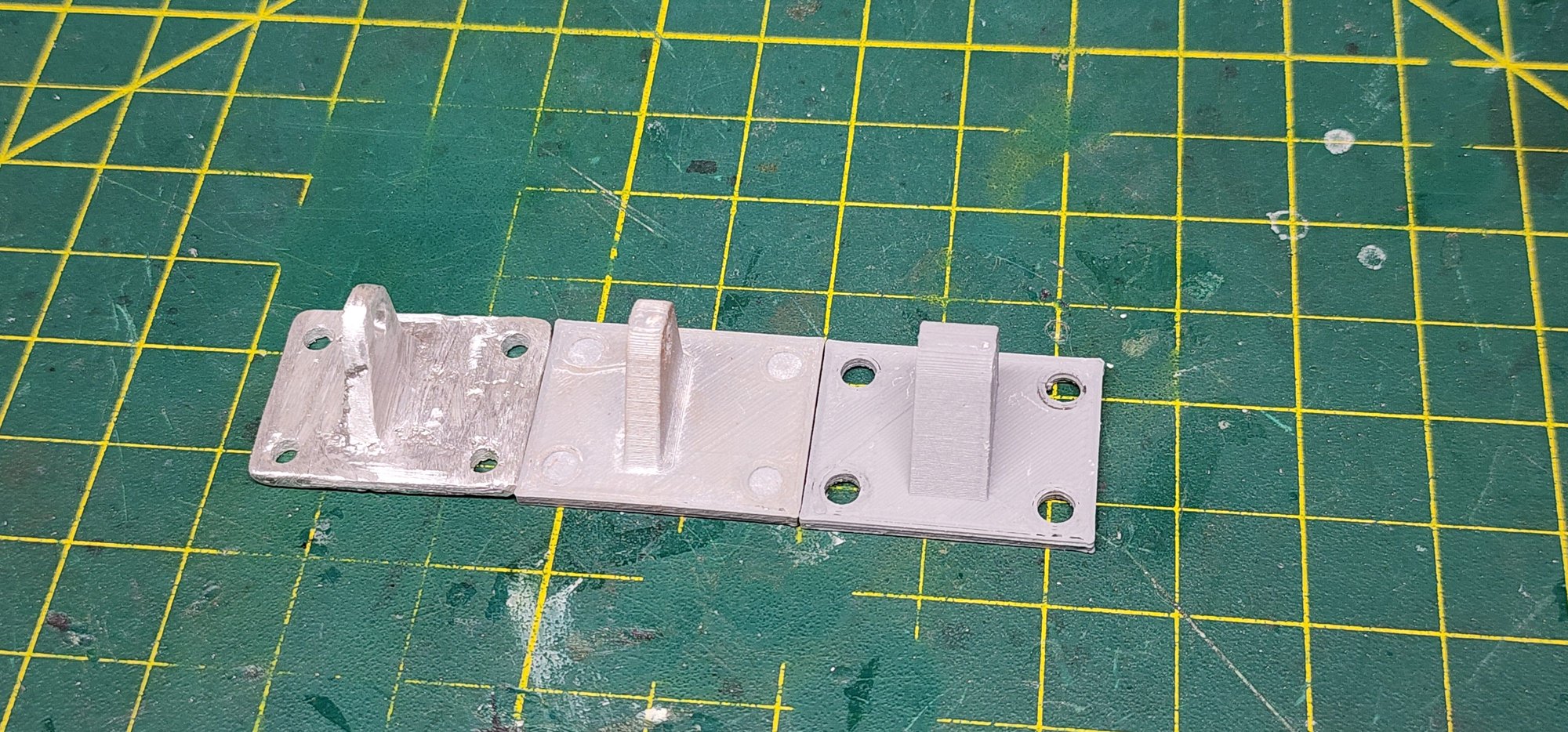

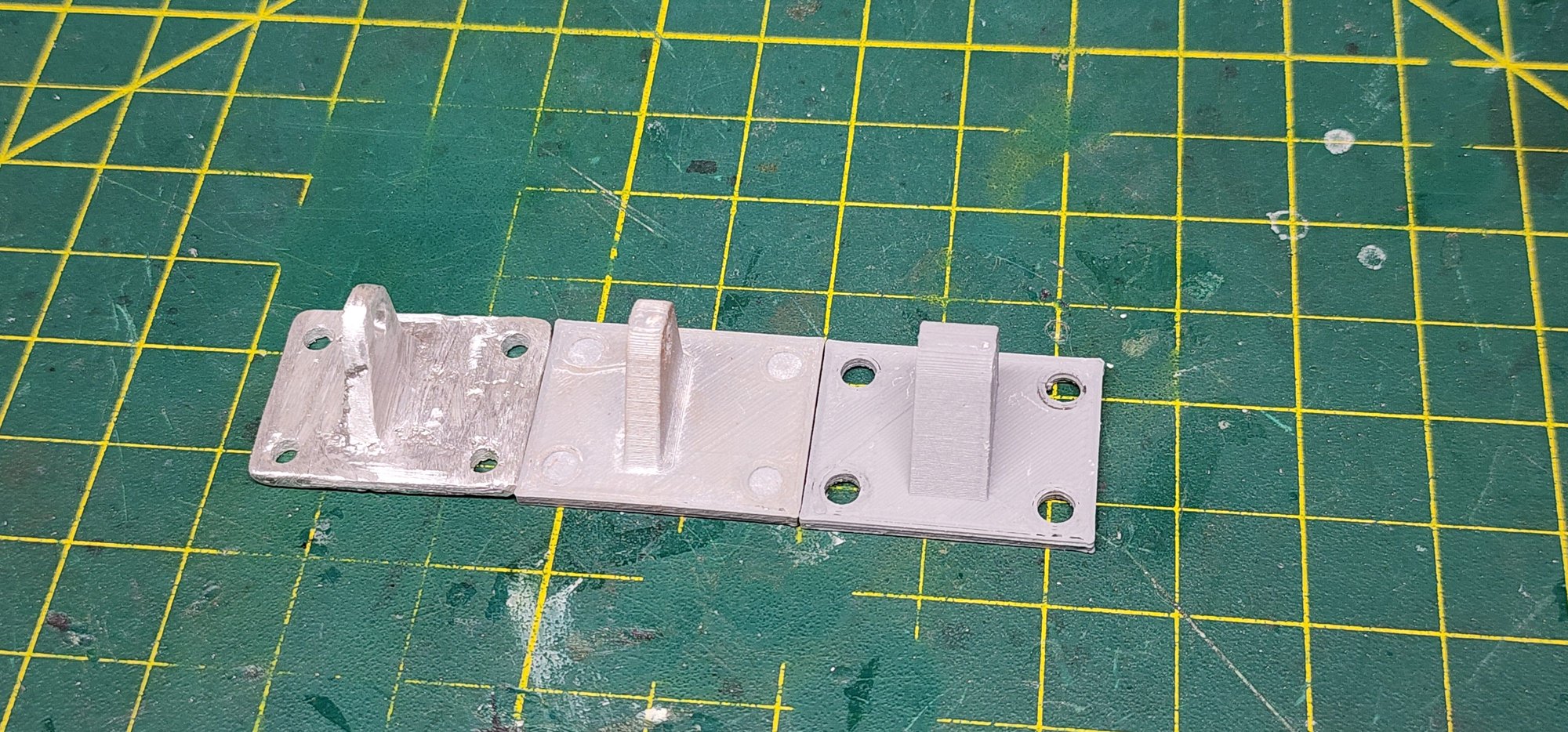

Alright, disregard... I ended up making my own hinge/servo horn. 3D printed it and then casted it into aluminum and all is good. The original servo horn is just no good and way too big. After a bit of work, the servo door now works great! Went from only moving half way to now way too far!

#28

My Feedback: (24)

Alright, disregard... I ended up making my own hinge/servo horn. 3D printed it and then casted it into aluminum and all is good. The original servo horn is just no good and way too big. After a bit of work, the servo door now works great! Went from only moving half way to now way too far!

Bob