Hsd t33

#1

Thread Starter

A few weeks ago here in the UK I sat looking at videos of the new HSD T33 and was impressed by its size and flying performance.

So inspired I tried ordering an EDF HSD T33 from the dealers in both Germany and Spain whom unfortunately will not have any stock until late next spring.

I then tried an online order from HSD Jets USA whom were helpful but returned the payment the next day, less £30 for the exchange difference, banks always win.

The order fell through and failed was because the shipping was going to be in excess of $1000!!!

My last port of call was to go to HSD China direct.It turns out they were happy to sell direct but it would still cost me $540 shipping and it took a lot of messing about sorting out payment.

By all accounts there are big problems in China with money laundering and HSD need a "recite of money sent" never heard of such a thing and it took some sorting out.

HSD China were fortunately sympathetic to the huge cost of shipping and as they were receiving full retail for the T33 rather than trade from there dealers were able to give me $100 discount.

Long story short I have now received a rather batted box all be it a day later than planed but it still only took about a week to get to me.

So inspired I tried ordering an EDF HSD T33 from the dealers in both Germany and Spain whom unfortunately will not have any stock until late next spring.

I then tried an online order from HSD Jets USA whom were helpful but returned the payment the next day, less £30 for the exchange difference, banks always win.

The order fell through and failed was because the shipping was going to be in excess of $1000!!!

My last port of call was to go to HSD China direct.It turns out they were happy to sell direct but it would still cost me $540 shipping and it took a lot of messing about sorting out payment.

By all accounts there are big problems in China with money laundering and HSD need a "recite of money sent" never heard of such a thing and it took some sorting out.

HSD China were fortunately sympathetic to the huge cost of shipping and as they were receiving full retail for the T33 rather than trade from there dealers were able to give me $100 discount.

Long story short I have now received a rather batted box all be it a day later than planed but it still only took about a week to get to me.

Last edited by Mark Vandervelden; 08-09-2020 at 09:11 AM.

#2

Thread Starter

There is a down side to ordering direct from HSD when they are on the other side of the world.

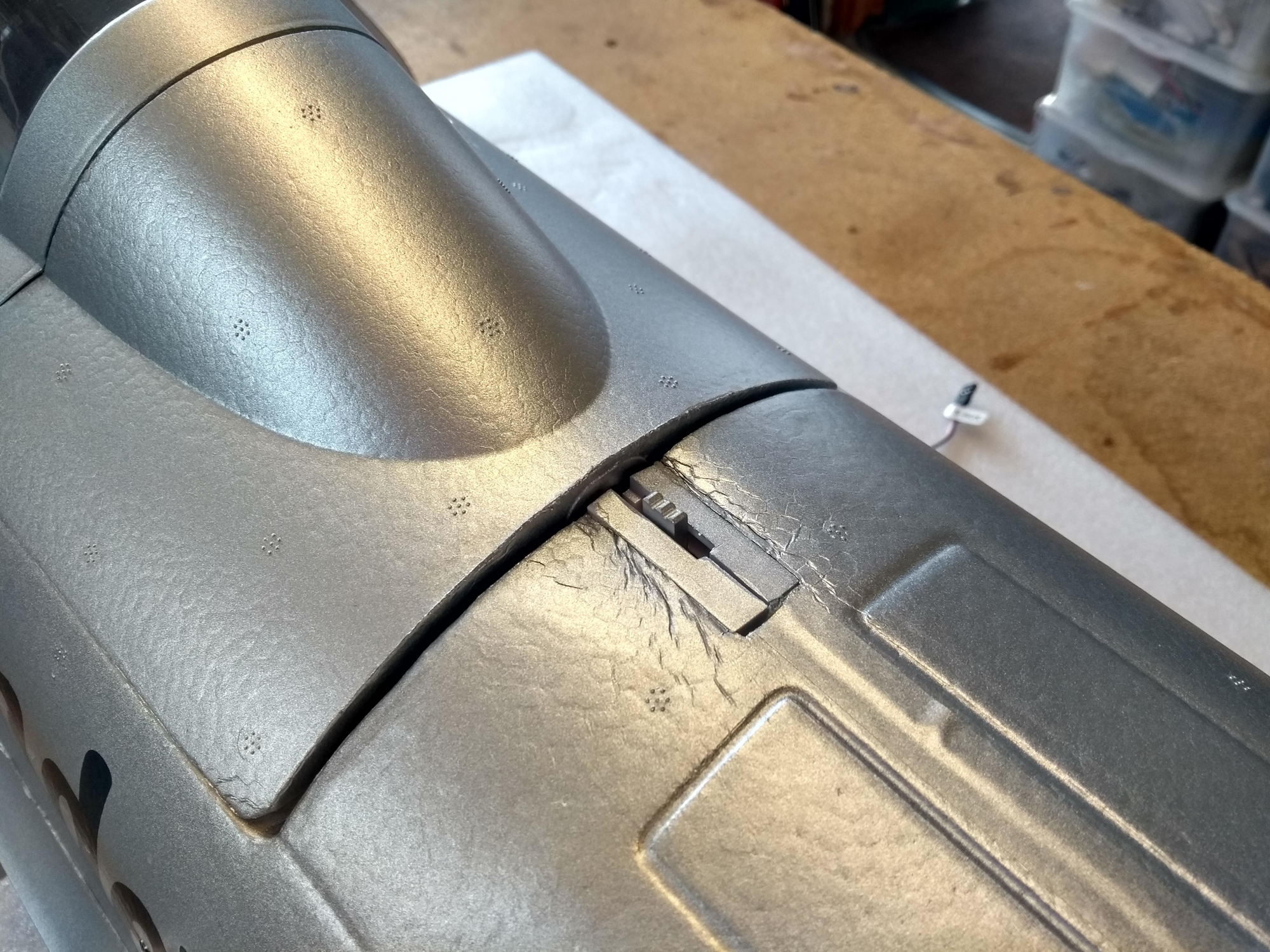

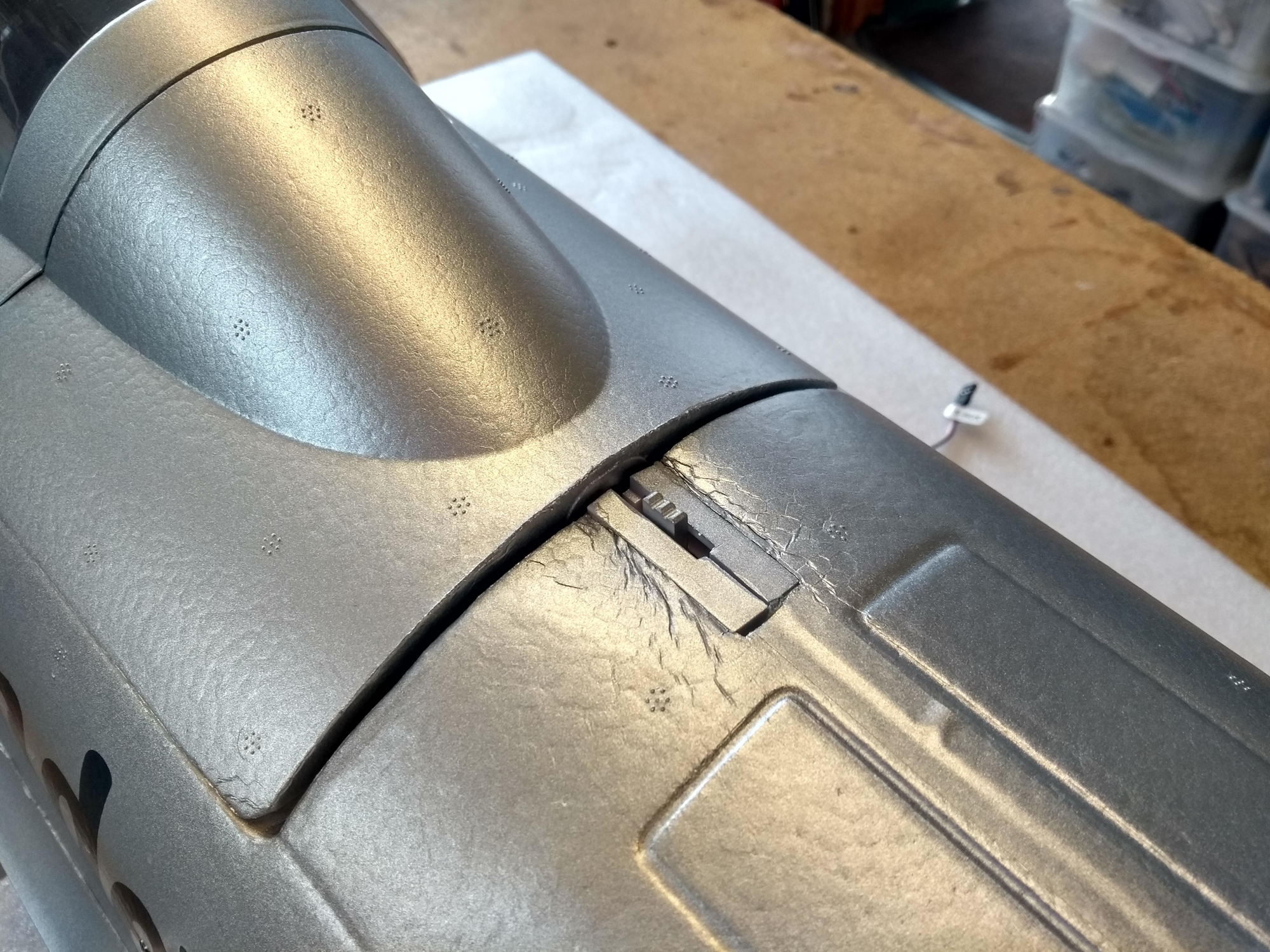

Unfortunately the HSD T33 was damaged in transit :-(

This was in part down to the shippers being the usual donkeys but the main problem was poor packing.

The main spare had migrated from it allotted slot in the huge molded foam packing and found its way to were the two fus half's sit and became trapped.

This unfortunately left a neat half round dent in the front nose section right at the base of were the canopy finishes.

It also crushed the canopy hatch latch at the front of the rear fus also were the canopy would sit.

This damage could have esialy been prevented with a small piece of tape across the slot were the spar sits, silly HSD

Other minor damage is to the lower gear door on the mains.

The wing sits in the box with the gear door up close the the top of the box with only 6mm of soft foam between it an the outer cardboard box.

The box was crushed at some time on it journey and the gear door is very vulnerable there so was snapped off its mount.

A small piece of foam pushed between the door and the leg would have easily supported the door and cost nothing?

Also the fin on the tip tank was damaged, not sure how as its deep in the box full protected so must have been damaged before it was packed, naughty HSD

The real problem foe me now is when you order a "gray import" from the other side of the world however it arrives it is yours to keep as its far too expensive to return.

So be warned, impatiens can bite you in the bottom :-)

Unfortunately the HSD T33 was damaged in transit :-(

This was in part down to the shippers being the usual donkeys but the main problem was poor packing.

The main spare had migrated from it allotted slot in the huge molded foam packing and found its way to were the two fus half's sit and became trapped.

This unfortunately left a neat half round dent in the front nose section right at the base of were the canopy finishes.

It also crushed the canopy hatch latch at the front of the rear fus also were the canopy would sit.

This damage could have esialy been prevented with a small piece of tape across the slot were the spar sits, silly HSD

Other minor damage is to the lower gear door on the mains.

The wing sits in the box with the gear door up close the the top of the box with only 6mm of soft foam between it an the outer cardboard box.

The box was crushed at some time on it journey and the gear door is very vulnerable there so was snapped off its mount.

A small piece of foam pushed between the door and the leg would have easily supported the door and cost nothing?

Also the fin on the tip tank was damaged, not sure how as its deep in the box full protected so must have been damaged before it was packed, naughty HSD

The real problem foe me now is when you order a "gray import" from the other side of the world however it arrives it is yours to keep as its far too expensive to return.

So be warned, impatiens can bite you in the bottom :-)

Last edited by Mark Vandervelden; 08-09-2020 at 09:21 AM.

#3

Thread Starter

On to the air frame itself

Its nicely finished, not quit on par with the smaller Freeing T33 but that T33 is a high bar for a foamy.

Assembly takes only an hour or two and everything fits OK but the joint between the front and rear fus are not 100% but close enough, no glue needed.

When together Its an impressive size and as long as its wide with the wing dead in the middle, its like a large cross!

The tip tanks give the T33 a feel of "size" and like the smaller FW offering will perhaps make it look even bigger in the air than it actually is.

.

Its nicely finished, not quit on par with the smaller Freeing T33 but that T33 is a high bar for a foamy.

Assembly takes only an hour or two and everything fits OK but the joint between the front and rear fus are not 100% but close enough, no glue needed.

When together Its an impressive size and as long as its wide with the wing dead in the middle, its like a large cross!

The tip tanks give the T33 a feel of "size" and like the smaller FW offering will perhaps make it look even bigger in the air than it actually is.

.

Last edited by Mark Vandervelden; 08-09-2020 at 01:31 AM.

#4

Thread Starter

First a complement and then a criticism!

The servos fitted to the HSD T33 are very good, very smooth and hold well.

"The Criticism" they have been installed by being glued in holes dug in the foam like a cheap toy foamy and cover with a piece of vinyl !.

The older "my older" HSD jets had a rather nice plastic servo box molded in to the foam with a very neat hatch held down with 4 discreet screws.

If these servos need to come out for any reason its a matter of digging them out possibly wrecking the finish of that part of the air frame, lets hope they are reliable.

I recommend if a servo packs up and you have a dealer close send it back and get the whole part or ask them to fit a new servo and paint it.

The servos fitted to the HSD T33 are very good, very smooth and hold well.

"The Criticism" they have been installed by being glued in holes dug in the foam like a cheap toy foamy and cover with a piece of vinyl !.

The older "my older" HSD jets had a rather nice plastic servo box molded in to the foam with a very neat hatch held down with 4 discreet screws.

If these servos need to come out for any reason its a matter of digging them out possibly wrecking the finish of that part of the air frame, lets hope they are reliable.

I recommend if a servo packs up and you have a dealer close send it back and get the whole part or ask them to fit a new servo and paint it.

Last edited by Mark Vandervelden; 08-09-2020 at 01:35 AM.

#5

Thread Starter

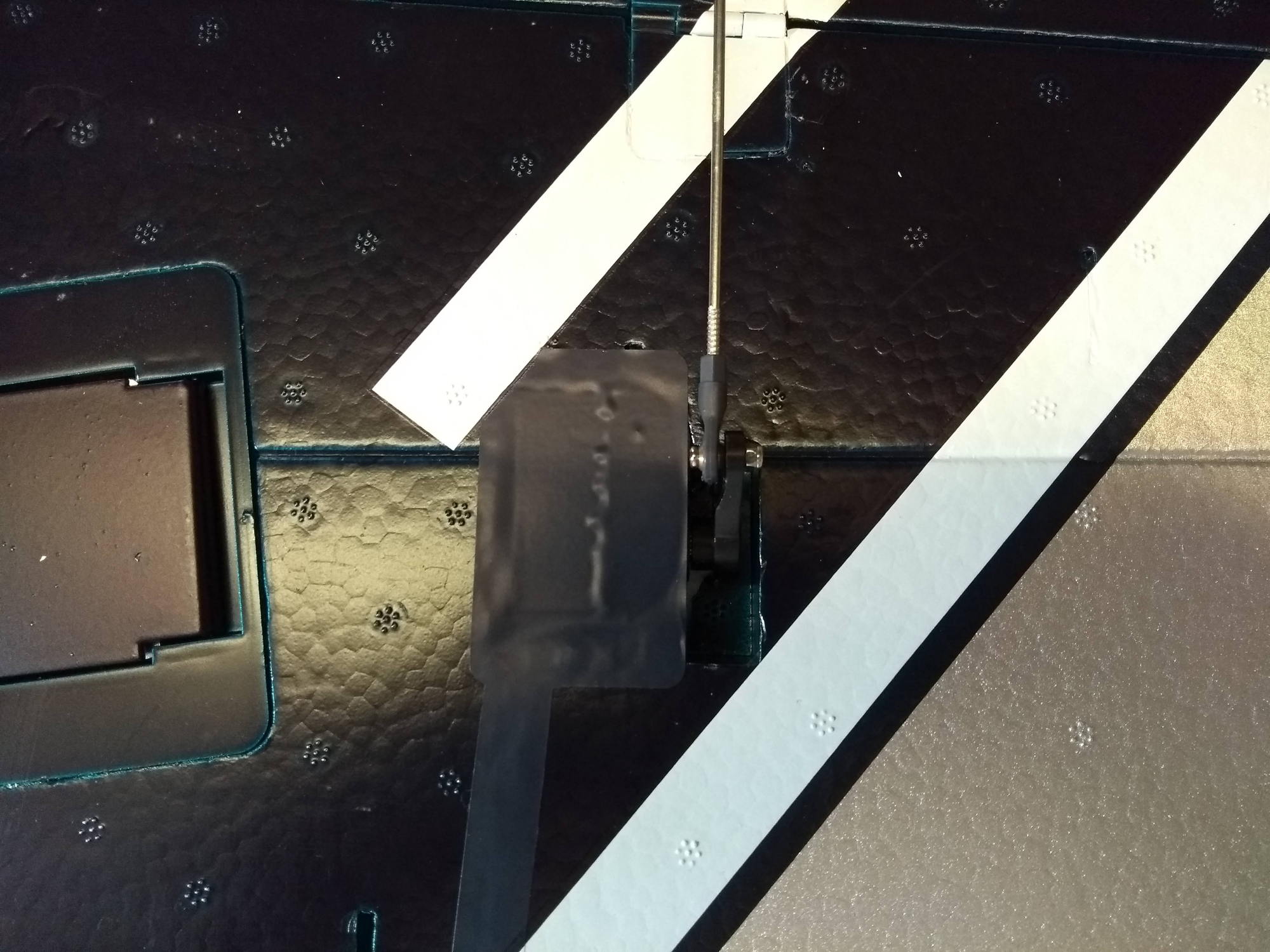

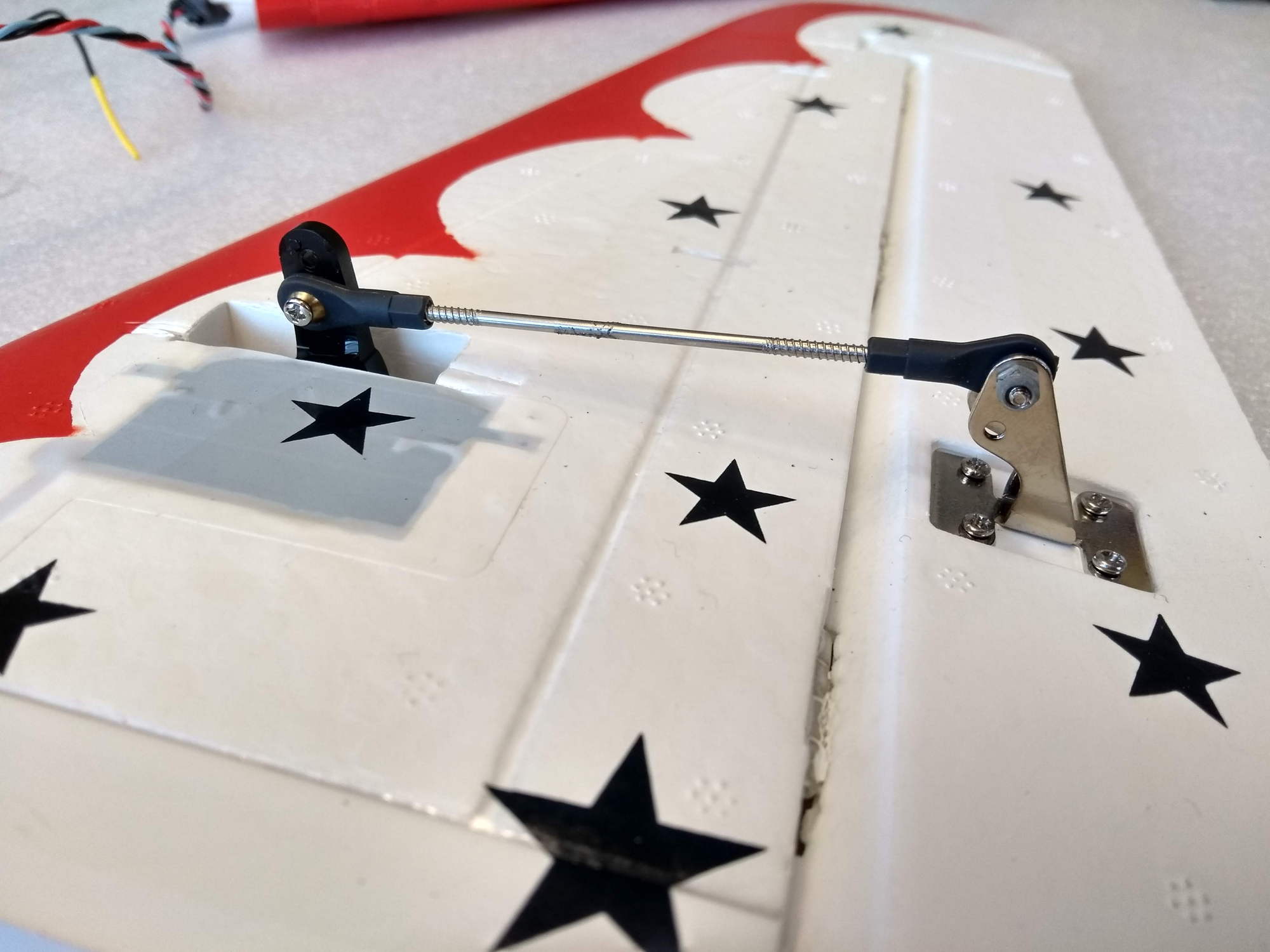

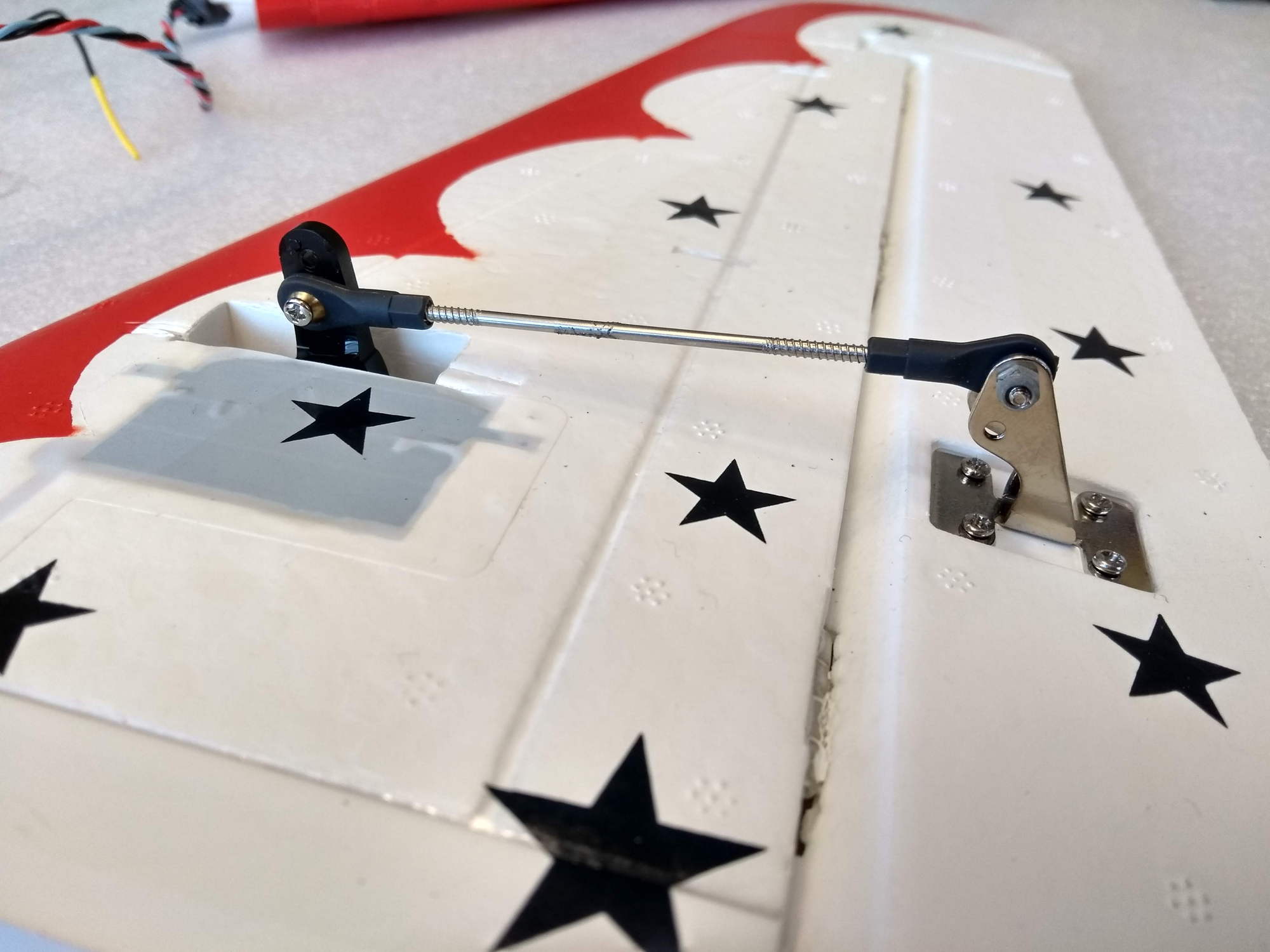

Servo geometry and throws.

As is the case with most ARTFs the setup is easy for them to fit at the factory but not an ideal setup for the end user.

As it comes from the factory to get the required control surface movement you will have to restrict the servo travel "a lot"

On the elevator to get the correct control surface movement the de-rate setting will be between 45-50%

this means the rather nice servos are running at half there advantage ie half power and half the available resolution.

An easy fix is to simply move the ball link on the servo arm one hole inward, this works on every control surface and gives full surface movement but now with 60-70% de-rate.

That is a huge improvement on stock install that costs nothing and is easy to do in very little time.

"But" I am a sucker for improvement and getting the best out of a given setup so on mine I went one further ;-)

I decided I would change all the servo arms (Futarba spline) for some smaller "shorter" ones and use a clevis instead of a ball link at the servo end.

This will help two fold, first to head towards a 100% servo movement.

Secondly, most of the servos are badly centered and arguably on the wrong spline requiring excessive sub trim, wile changing the output arms it gives me to opportunity to correct this

To remove the old servo arms you need to poke a 2.5mm hex driver through the foam about 45mm away from the servo head to engage the servo screw.

This only leaves a small hole which is underneath so no big deal, would have been easy with servo boxes and hatches but not having those saves HSD a few dollars?

I then used 2.5mm clevises and 2.5mm threaded rod to make up new push rods, result is a neater looking linkage with 90-100% servo travel on everything but the flap that now needs 110%.

As is the case with most ARTFs the setup is easy for them to fit at the factory but not an ideal setup for the end user.

As it comes from the factory to get the required control surface movement you will have to restrict the servo travel "a lot"

On the elevator to get the correct control surface movement the de-rate setting will be between 45-50%

this means the rather nice servos are running at half there advantage ie half power and half the available resolution.

An easy fix is to simply move the ball link on the servo arm one hole inward, this works on every control surface and gives full surface movement but now with 60-70% de-rate.

That is a huge improvement on stock install that costs nothing and is easy to do in very little time.

"But" I am a sucker for improvement and getting the best out of a given setup so on mine I went one further ;-)

I decided I would change all the servo arms (Futarba spline) for some smaller "shorter" ones and use a clevis instead of a ball link at the servo end.

This will help two fold, first to head towards a 100% servo movement.

Secondly, most of the servos are badly centered and arguably on the wrong spline requiring excessive sub trim, wile changing the output arms it gives me to opportunity to correct this

To remove the old servo arms you need to poke a 2.5mm hex driver through the foam about 45mm away from the servo head to engage the servo screw.

This only leaves a small hole which is underneath so no big deal, would have been easy with servo boxes and hatches but not having those saves HSD a few dollars?

I then used 2.5mm clevises and 2.5mm threaded rod to make up new push rods, result is a neater looking linkage with 90-100% servo travel on everything but the flap that now needs 110%.

Last edited by Mark Vandervelden; 08-09-2020 at 07:24 AM. Reason: spelling corection

#6

Thread Starter

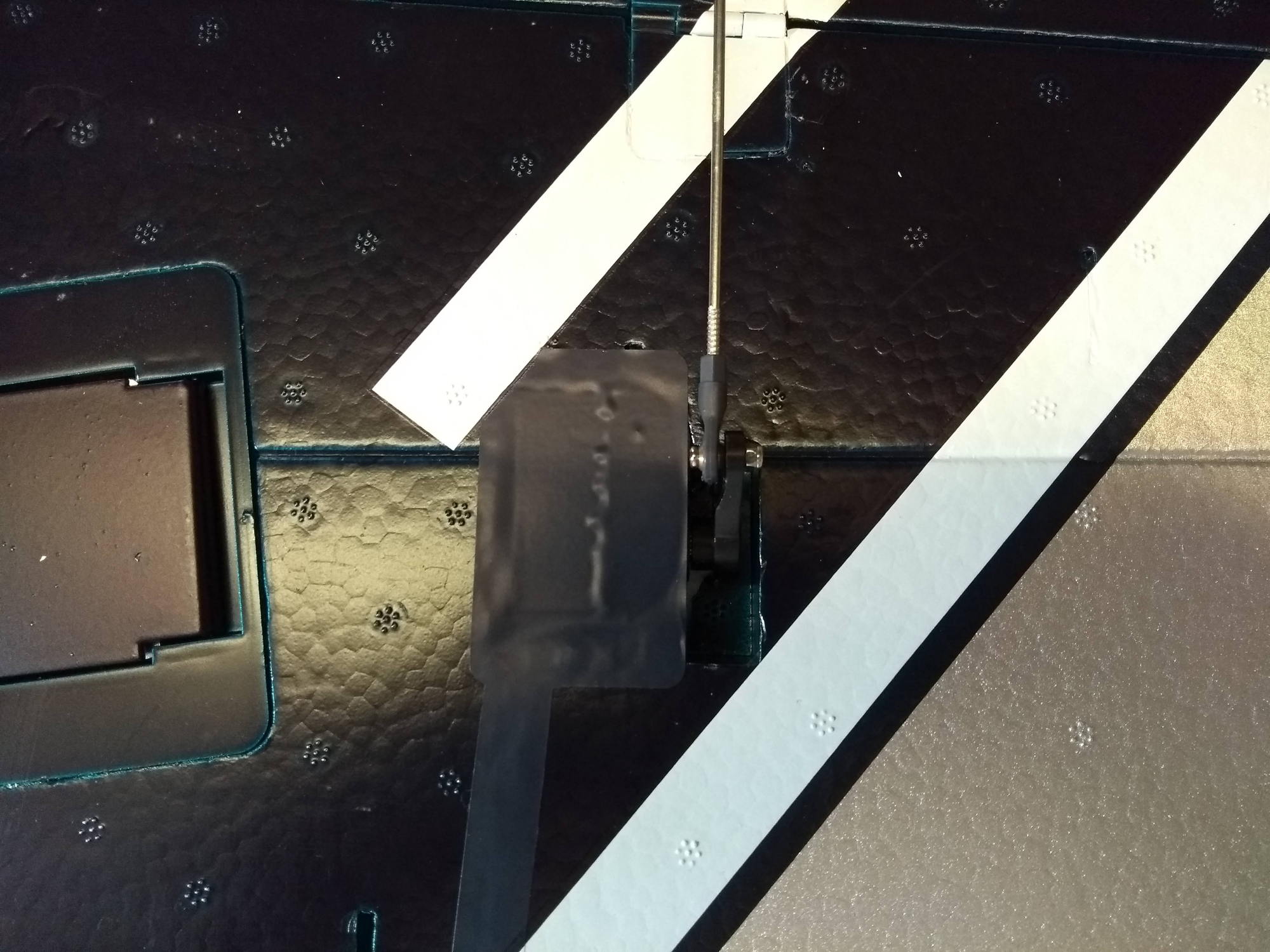

Rudder linkage rookie mistake at factory :-/ "Advice" always check all your linkages folks, you know it makes sense!!

The rudder linkage push rod on my HSD T33 was a tad short but not a problem for me as I changed them all anyway.

What I found was that the rudder linkage had been trimmed in length but with side cutters!! we all should be aware this is a rookie mistake.

The end of the push rod is then splayed wide and has a chisel point, this ruins the plastic ball link when it screwed in and can let go under load, nasty

This cant bee seen with a simple visual inspection, you would have to unscrew the linkage to see if its OK.

end now wider than the thread

other end untouched

The rudder linkage push rod on my HSD T33 was a tad short but not a problem for me as I changed them all anyway.

What I found was that the rudder linkage had been trimmed in length but with side cutters!! we all should be aware this is a rookie mistake.

The end of the push rod is then splayed wide and has a chisel point, this ruins the plastic ball link when it screwed in and can let go under load, nasty

This cant bee seen with a simple visual inspection, you would have to unscrew the linkage to see if its OK.

end now wider than the thread

other end untouched

Last edited by Mark Vandervelden; 08-09-2020 at 07:20 AM.

#7

Thread Starter

Wobbly fin any one

The tail-planes and fin are retained with two fixings in each surface were they meet the fuselage on plastic molded mating surfaces, very neat and easy.

This works well with the tail planes as they have a full length carbon spar going virtually from tip to tip making everything nice and stiff but easy to remove.

Unfortunately this is not the case with the fin, its merely sits on a plastic molded saddle and has little side ward support.

On mine this shows up as excessive side ways fin wobble. I have seen other examples that do not wobble at all so haven't a clue whats wrong with mine, last thing Friday night at the factory job?

I cant seem load the video so here is a link to it on YouTube

The tail-planes and fin are retained with two fixings in each surface were they meet the fuselage on plastic molded mating surfaces, very neat and easy.

This works well with the tail planes as they have a full length carbon spar going virtually from tip to tip making everything nice and stiff but easy to remove.

Unfortunately this is not the case with the fin, its merely sits on a plastic molded saddle and has little side ward support.

On mine this shows up as excessive side ways fin wobble. I have seen other examples that do not wobble at all so haven't a clue whats wrong with mine, last thing Friday night at the factory job?

I cant seem load the video so here is a link to it on YouTube

Last edited by Mark Vandervelden; 08-09-2020 at 07:18 AM.

#9

Thread Starter

The Tip Tanks on this HSD T33 have 6 oz of old iron in there nose "Why" Well here is what I found out.

asked HSD China several times "no answer" I then saw the same question on HSD Owners of FB a few weeks ago, that remained unanswered, very strange, what are they hideing?

So in an effort to get to the bottom of it I asked HSD Jets USA on there FB page the same question again myself just a day or so ago.

One guy that works at HSD Jets USA told be it was to help with CG? and also to stop the wing from fluttering!!

This is not unheard of in full size aviation but model aircraft are usually inherently "stiffer" than full size aircraft, try doing what we do with model aircraft on a full size version and see how long it lasts!!

Well the CG angel is a non starter, The 6oz of ballast in the tip tanks is a mere 3.1/2" in front of the CG, the nose on the other hand is 3 feet in front of the CG so about a 1/4-1/2oz would do that same job :-)

Add to that this EDF version carries over 3lbs of battery in the nose so forget even the 1/4oz of ballast and simply move the battery forward a fraction of an inch?

As for stopping "WING FLUTTER" that is another matter! The wing on the HSD T33 has two carbon spars molded inon its wings in an "A" configuration.

This is OK for the up-down stress on the wing but poor for the torsional forces the wing endures for when at speed the center of pressure moves fore and aft during different speeds and angels of attack.

That center of pressure induces a twisting effect on a wing add to that the wing shedding vortices along its length can start to flutter, if that wing is soft it could be quite bad

This HSD T33 being a Foamy is probably pushing the limit of size for a Foamy, its skin is not that stiff unlike say an epoxy molded construction or full balsa sheet wing, so this one will flex.

I would rather have seen and aerodynamic or structural solution but we have what we have and a heavy dynamic damper is HSDs answer like it or not so "Dont take the iron out"!!

I think HSD should have be more candid as to why it has ballast in its tip tanks, they obviously know with out it there could be a big problem or it would not be there in the first place.

Add to that the wings have a proper formed tip, its inviting for us to remove the tip tanks and fly just like some full size T33 fly without them but I now would not advise that!

There is of course a huge down side to having ballast right out on the wing tips, in the event of a spin or a tip-stall those inertia dampeners do the opposite and maintain the spin. oh dear

There are plenty of videos online of this and other T33 air frames flicking out of knife edge and sometimes just a show pass attitude so I for one will be careful not to tease this example.

I note that I know of no other model T33 employing tip weights and not all T33s behave badly in knife edge, My FW T33 behave impeccably in knife edge for as long as I can hold it

"Some old iron comes free with every HSD T33" Nice rhyme dont you think :-)

asked HSD China several times "no answer" I then saw the same question on HSD Owners of FB a few weeks ago, that remained unanswered, very strange, what are they hideing?

So in an effort to get to the bottom of it I asked HSD Jets USA on there FB page the same question again myself just a day or so ago.

One guy that works at HSD Jets USA told be it was to help with CG? and also to stop the wing from fluttering!!

This is not unheard of in full size aviation but model aircraft are usually inherently "stiffer" than full size aircraft, try doing what we do with model aircraft on a full size version and see how long it lasts!!

Well the CG angel is a non starter, The 6oz of ballast in the tip tanks is a mere 3.1/2" in front of the CG, the nose on the other hand is 3 feet in front of the CG so about a 1/4-1/2oz would do that same job :-)

Add to that this EDF version carries over 3lbs of battery in the nose so forget even the 1/4oz of ballast and simply move the battery forward a fraction of an inch?

As for stopping "WING FLUTTER" that is another matter! The wing on the HSD T33 has two carbon spars molded inon its wings in an "A" configuration.

This is OK for the up-down stress on the wing but poor for the torsional forces the wing endures for when at speed the center of pressure moves fore and aft during different speeds and angels of attack.

That center of pressure induces a twisting effect on a wing add to that the wing shedding vortices along its length can start to flutter, if that wing is soft it could be quite bad

This HSD T33 being a Foamy is probably pushing the limit of size for a Foamy, its skin is not that stiff unlike say an epoxy molded construction or full balsa sheet wing, so this one will flex.

I would rather have seen and aerodynamic or structural solution but we have what we have and a heavy dynamic damper is HSDs answer like it or not so "Dont take the iron out"!!

I think HSD should have be more candid as to why it has ballast in its tip tanks, they obviously know with out it there could be a big problem or it would not be there in the first place.

Add to that the wings have a proper formed tip, its inviting for us to remove the tip tanks and fly just like some full size T33 fly without them but I now would not advise that!

There is of course a huge down side to having ballast right out on the wing tips, in the event of a spin or a tip-stall those inertia dampeners do the opposite and maintain the spin. oh dear

There are plenty of videos online of this and other T33 air frames flicking out of knife edge and sometimes just a show pass attitude so I for one will be careful not to tease this example.

I note that I know of no other model T33 employing tip weights and not all T33s behave badly in knife edge, My FW T33 behave impeccably in knife edge for as long as I can hold it

"Some old iron comes free with every HSD T33" Nice rhyme dont you think :-)

Last edited by Mark Vandervelden; 08-09-2020 at 03:29 AM. Reason: spelling corection

#10

Thread Starter

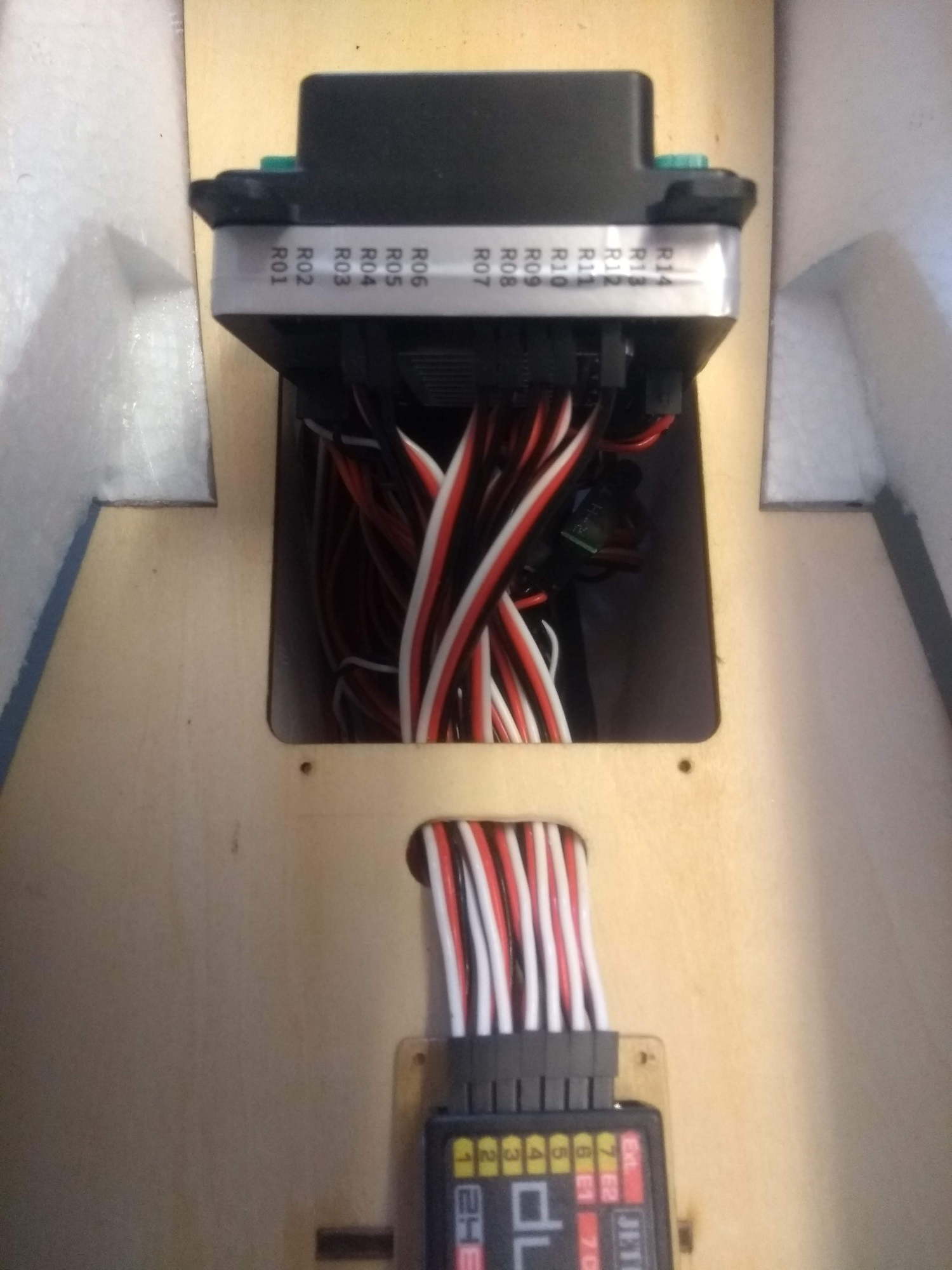

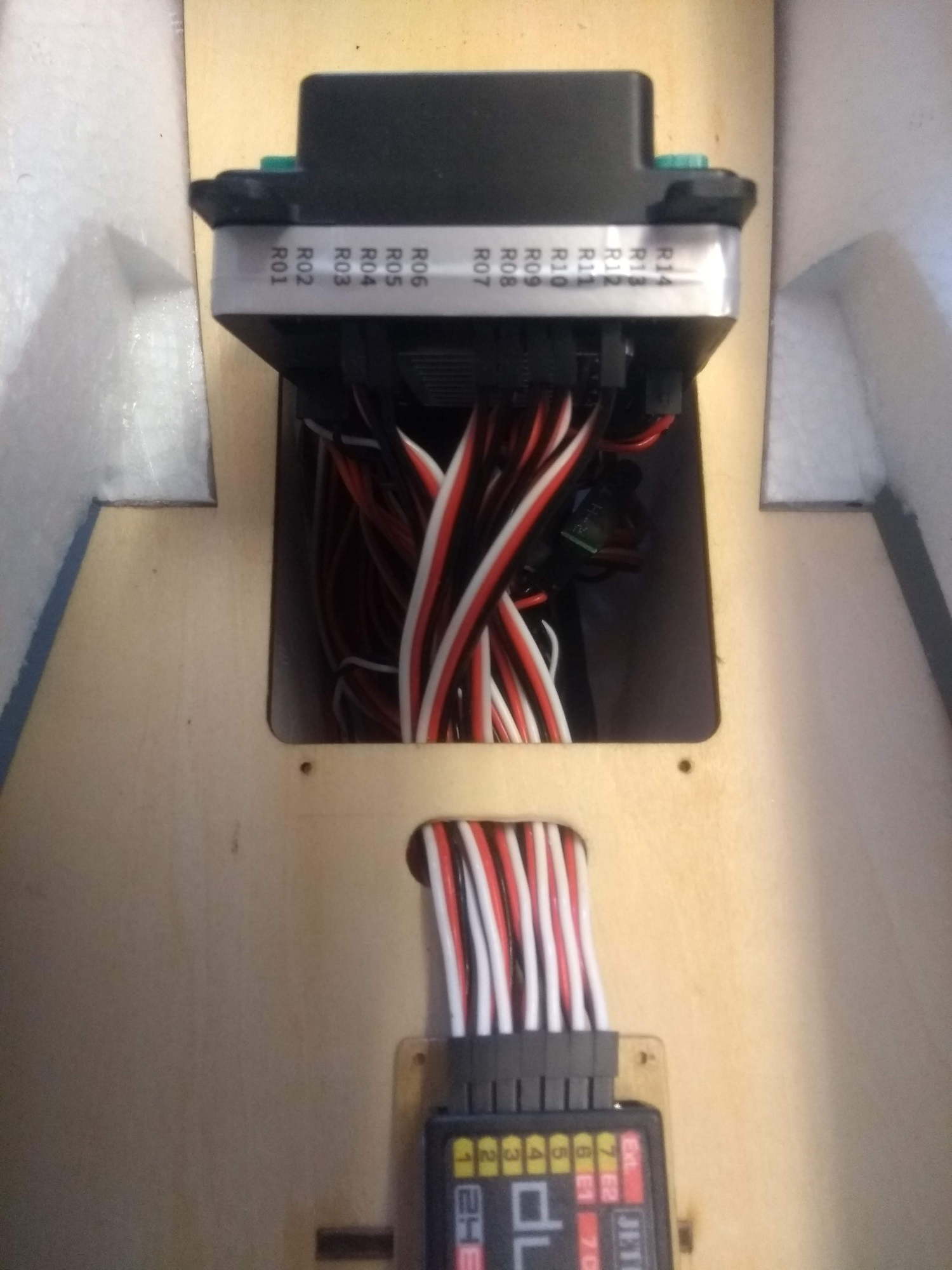

Lead layout from the Rx for the fly leads into the control box for your reference as the manual is a bit confusing.

Control Box socket R03-Gear, R04-Brakes, R07-Aile, R08-Elev, R09-Rud, R10-Flap and R12-Throttle..

The fly leads plug into the control box have there signal wire (White) to the center of the box.

7ch are required, pairing of Ailerons, Elevator, Flaps, Rudder with Nose wheel steering is taken care of in the control box.

As far as I can tell the control box also has servo slow for flaps, switches off the nose wheel steering when the gear is retracted.

Sub trim, servo revers and travel adjust is also all dealt with in the Control Box it self the Tx is recommended to be set to 100% travel.

Im not sure about if it has Flap to Elevator mix compensation, watch this space, if it has I will dile it out and use my TXs modes to set the trims in any case

This picture is looking from the rear of the air frame forward as I have turned the control box 180 deg from stock install., HSD actually expect you to have the Rx at the front up on top of the power and flight battery in the nose!!

Control Box socket R03-Gear, R04-Brakes, R07-Aile, R08-Elev, R09-Rud, R10-Flap and R12-Throttle..

The fly leads plug into the control box have there signal wire (White) to the center of the box.

7ch are required, pairing of Ailerons, Elevator, Flaps, Rudder with Nose wheel steering is taken care of in the control box.

As far as I can tell the control box also has servo slow for flaps, switches off the nose wheel steering when the gear is retracted.

Sub trim, servo revers and travel adjust is also all dealt with in the Control Box it self the Tx is recommended to be set to 100% travel.

Im not sure about if it has Flap to Elevator mix compensation, watch this space, if it has I will dile it out and use my TXs modes to set the trims in any case

This picture is looking from the rear of the air frame forward as I have turned the control box 180 deg from stock install., HSD actually expect you to have the Rx at the front up on top of the power and flight battery in the nose!!

#12

Hi Mark,

Great review you have on this T33. I too bought a HSD but unfortunately crashed it while doing the 3rd flight ( 2 flights by my friend who is an experience flyer ) I flew the 3rd flight and plane crash. Could be a rudder problem when plane is banking too much close to knife edge. Managed to salvage most of the electronics thou the fan is gone. I ordered a new kit but now seems hesitant as what i read from your thread, most servos are glued rather than screwed on. This means I have to dig out every servos from my crashed plane to have it glue to the new one. Also I’m at a loss as to hide those bulk of wires. Will need to see the kit first when it arrives.

regards

Great review you have on this T33. I too bought a HSD but unfortunately crashed it while doing the 3rd flight ( 2 flights by my friend who is an experience flyer ) I flew the 3rd flight and plane crash. Could be a rudder problem when plane is banking too much close to knife edge. Managed to salvage most of the electronics thou the fan is gone. I ordered a new kit but now seems hesitant as what i read from your thread, most servos are glued rather than screwed on. This means I have to dig out every servos from my crashed plane to have it glue to the new one. Also I’m at a loss as to hide those bulk of wires. Will need to see the kit first when it arrives.

regards

#13

Join Date: Sep 2009

Location: ST. CLAIR, AUSTRALIA

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Hi Mark,

I bought one of these JETS recently and yes mine has the same amount of weight in the wing tanks. I could not find anything about your test flight so I wonder how you end flying the model. Is it still EDF or you wen turbine?

Did you do any reinforcement for the wings?

I'm curious what were your conslusions.

Best regards from Australia,

EUGEN IOV

I bought one of these JETS recently and yes mine has the same amount of weight in the wing tanks. I could not find anything about your test flight so I wonder how you end flying the model. Is it still EDF or you wen turbine?

Did you do any reinforcement for the wings?

I'm curious what were your conslusions.

Best regards from Australia,

EUGEN IOV