KJ66 Shaft Bearings

#1

Thread Starter

Join Date: Jan 2007

Location: Olathe, KS

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

What is the correct way to install Bearings on the Shaft?

I have a KJ66 engine with rear pre-load and using the 608 GRW Ceramic Bearings.

The inner race of the Bearing has a larger dia. on one side and smaller dia. on the other end, do you place the Bearings on the shaft

with the smaller dia. of the race facing inwards on the shaft on both Bearings or is this iincorrect.?

Thanks,

Steve

I have a KJ66 engine with rear pre-load and using the 608 GRW Ceramic Bearings.

The inner race of the Bearing has a larger dia. on one side and smaller dia. on the other end, do you place the Bearings on the shaft

with the smaller dia. of the race facing inwards on the shaft on both Bearings or is this iincorrect.?

Thanks,

Steve

#2

Thread Starter

Join Date: Jan 2007

Location: Olathe, KS

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

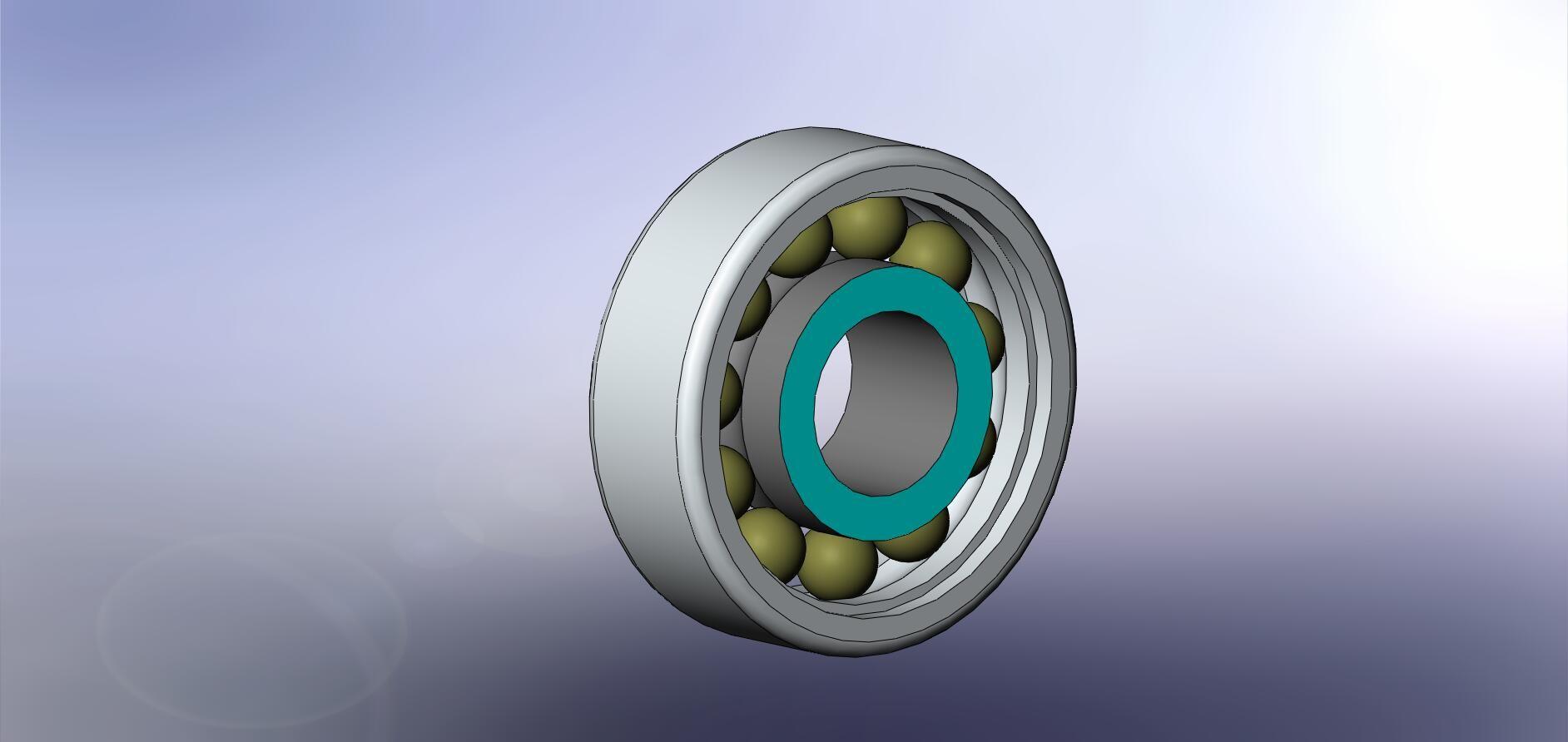

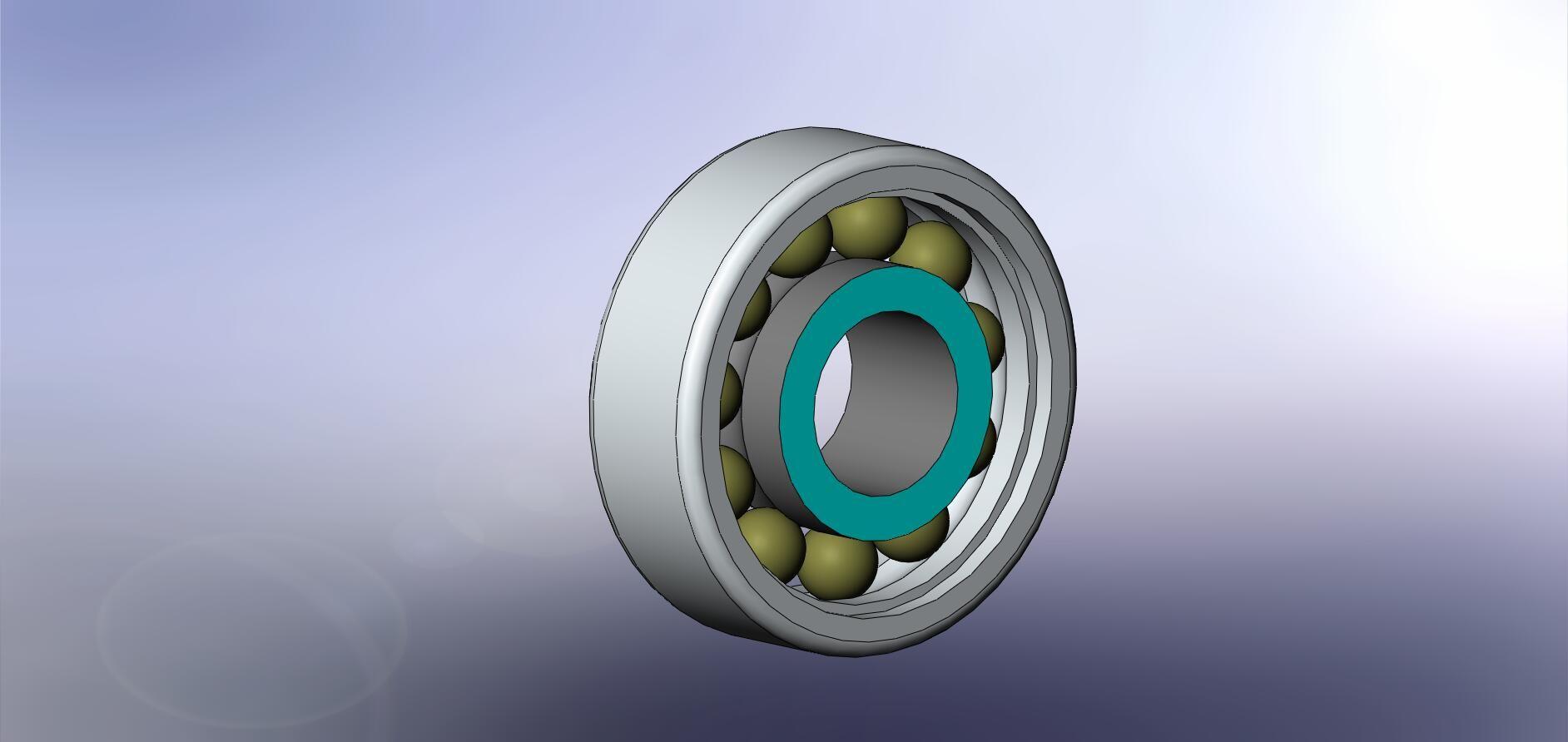

I have attached some pictures that may help explain my question on the correct way to install bearings on the Shaft.

the #1 picture is what I reference as the larger diameter of the inner race.

the #2 picture is what I reference as the smaller diameter of the inner race.

Thanks,

Steve

#2

#1

the #1 picture is what I reference as the larger diameter of the inner race.

the #2 picture is what I reference as the smaller diameter of the inner race.

Thanks,

Steve

#2

#1

#3

GRW 608 bearings have a distinct arrow on the outer race which needs to point out to the outer surface of the engine. Also on the 608 GRW, the inner race is tapered. The wider end of the inner race points out from the center.

What is the correct way to install Bearings on the Shaft?

I have a KJ66 engine with rear pre-load and using the 608 GRW Ceramic Bearings.

The inner race of the Bearing has a larger dia. on one side and smaller dia. on the other end, do you place the Bearings on the shaft

with the smaller dia. of the race facing inwards on the shaft on both Bearings or is this iincorrect.?

Thanks,

Steve

I have a KJ66 engine with rear pre-load and using the 608 GRW Ceramic Bearings.

The inner race of the Bearing has a larger dia. on one side and smaller dia. on the other end, do you place the Bearings on the shaft

with the smaller dia. of the race facing inwards on the shaft on both Bearings or is this iincorrect.?

Thanks,

Steve

#4

Thread Starter

Join Date: Jan 2007

Location: Olathe, KS

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Thank You So much for your Reply!!

Looks like I had it right with facing the Wider End of the Race facing outwards on both ends of the shaft..

The 608 GRW Bearings I have do not have the arrow you are showing in your pictures, so I am thinking I do not have original 608 GRW Bearings but maybe a knockoff from china or something.

I am pretty sure I bought these from Boca Bearings and said they were 608 GRW bearings (8 to 10 years ago).

I have only ran this engine a couple of times but wanted to get it up and running again.

Where would you recommend buying GRW 608 Bearings?

Also I need the Shaft Assy Balanced , could I send it to your factory for a Balance?

Thanks again!

Steve Briar

Looks like I had it right with facing the Wider End of the Race facing outwards on both ends of the shaft..

The 608 GRW Bearings I have do not have the arrow you are showing in your pictures, so I am thinking I do not have original 608 GRW Bearings but maybe a knockoff from china or something.

I am pretty sure I bought these from Boca Bearings and said they were 608 GRW bearings (8 to 10 years ago).

I have only ran this engine a couple of times but wanted to get it up and running again.

Where would you recommend buying GRW 608 Bearings?

Also I need the Shaft Assy Balanced , could I send it to your factory for a Balance?

Thanks again!

Steve Briar

#5

GRW bearings absolutely have the arrow. There are a lot of others out there. Some are different. Some have a tapered inner race while others have a tapered outer race. GRW 6000 series are different from 608 but all GRW bearings have the telltale arrow. Other brands are not necessarily inferior but the designs can differ.

If you need your finished armature balanced call us 716.946.7493 and please don't run the turbine before balancing it.

Andy Fioretti

CRX Turbines

If you need your finished armature balanced call us 716.946.7493 and please don't run the turbine before balancing it.

Andy Fioretti

CRX Turbines

Thank You So much for your Reply!!

Looks like I had it right with facing the Wider End of the Race facing outwards on both ends of the shaft..

The 608 GRW Bearings I have do not have the arrow you are showing in your pictures, so I am thinking I do not have original 608 GRW Bearings but maybe a knockoff from china or something.

I am pretty sure I bought these from Boca Bearings and said they were 608 GRW bearings (8 to 10 years ago).

I have only ran this engine a couple of times but wanted to get it up and running again.

https://www.youtube.com/watch?v=bWgQBU7PAb0

Where would you recommend buying GRW 608 Bearings?

Also I need the Shaft Assy Balanced , could I send it to your factory for a Balance?

Thanks again!

Steve Briar

Looks like I had it right with facing the Wider End of the Race facing outwards on both ends of the shaft..

The 608 GRW Bearings I have do not have the arrow you are showing in your pictures, so I am thinking I do not have original 608 GRW Bearings but maybe a knockoff from china or something.

I am pretty sure I bought these from Boca Bearings and said they were 608 GRW bearings (8 to 10 years ago).

I have only ran this engine a couple of times but wanted to get it up and running again.

https://www.youtube.com/watch?v=bWgQBU7PAb0

Where would you recommend buying GRW 608 Bearings?

Also I need the Shaft Assy Balanced , could I send it to your factory for a Balance?

Thanks again!

Steve Briar

#6

Junior Member

Join Date: Mar 2019

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

Hi all,

I would like to reuse this thread, hope it is OK.

I have KJ-66 short time after bearings exchange and rebalancing. I’ve run it on a test stand for about 4..5 minutes with two 10..20s runs on full throttle (120 000rpm). It run quite well with the exception of high EGT (about 780 C). After the stop and cool down I’ve noticed the shaft is not fully free but it loosened completely after some moves with fingers. Today I continued with tests and I noticed that yesterday I’ve probably swapped the propane and kero inputs so I fed it though propane input. I am not fully sure about that because I disconnected both tubes between while however, I remember I had stuck gas valve on the begin yesterday so I was rewiring some stuff and here most probably swapping of the inputs happened. Quite stupid mistake I know. Today with 100% correct plumbing also the EGT was OK about 500..600 C.

Here my question: because of yesterday’s run completely without lubrication: should I let rebuild the turbine with new bearings? The feeling of the bearings subjectively looks be smooth just as before yesterday’s run without lubrication of bearings.

Thanks much for your advices.

I would like to reuse this thread, hope it is OK.

I have KJ-66 short time after bearings exchange and rebalancing. I’ve run it on a test stand for about 4..5 minutes with two 10..20s runs on full throttle (120 000rpm). It run quite well with the exception of high EGT (about 780 C). After the stop and cool down I’ve noticed the shaft is not fully free but it loosened completely after some moves with fingers. Today I continued with tests and I noticed that yesterday I’ve probably swapped the propane and kero inputs so I fed it though propane input. I am not fully sure about that because I disconnected both tubes between while however, I remember I had stuck gas valve on the begin yesterday so I was rewiring some stuff and here most probably swapping of the inputs happened. Quite stupid mistake I know. Today with 100% correct plumbing also the EGT was OK about 500..600 C.

Here my question: because of yesterday’s run completely without lubrication: should I let rebuild the turbine with new bearings? The feeling of the bearings subjectively looks be smooth just as before yesterday’s run without lubrication of bearings.

Thanks much for your advices.

#7

If the run was short then you will more than likely be ok. 780 is not the end of the world. What is the temp at idle? You know that this temp reading is altogether based on how far the temp probe is into the tail cone so if too high pull the probe out a small amount. The temp of the bearings is far lower being at the center and with some air riding along the back of the compressor and down the shaft.

I would try running it and if the problem persists or gets worse then change the bearings but it sounds like you will be ok, If you did by chance do anything wrong, the tail bearing woudl be the one to suffer, not so much the front.

Andy

I would try running it and if the problem persists or gets worse then change the bearings but it sounds like you will be ok, If you did by chance do anything wrong, the tail bearing woudl be the one to suffer, not so much the front.

Andy

Hi all,

I would like to reuse this thread, hope it is OK.

I have KJ-66 short time after bearings exchange and rebalancing. I’ve run it on a test stand for about 4..5 minutes with two 10..20s runs on full throttle (120 000rpm). It run quite well with the exception of high EGT (about 780 C). After the stop and cool down I’ve noticed the shaft is not fully free but it loosened completely after some moves with fingers. Today I continued with tests and I noticed that yesterday I’ve probably swapped the propane and kero inputs so I fed it though propane input. I am not fully sure about that because I disconnected both tubes between while however, I remember I had stuck gas valve on the begin yesterday so I was rewiring some stuff and here most probably swapping of the inputs happened. Quite stupid mistake I know. Today with 100% correct plumbing also the EGT was OK about 500..600 C.

Here my question: because of yesterday’s run completely without lubrication: should I let rebuild the turbine with new bearings? The feeling of the bearings subjectively looks be smooth just as before yesterday’s run without lubrication of bearings.

Thanks much for your advices.

I would like to reuse this thread, hope it is OK.

I have KJ-66 short time after bearings exchange and rebalancing. I’ve run it on a test stand for about 4..5 minutes with two 10..20s runs on full throttle (120 000rpm). It run quite well with the exception of high EGT (about 780 C). After the stop and cool down I’ve noticed the shaft is not fully free but it loosened completely after some moves with fingers. Today I continued with tests and I noticed that yesterday I’ve probably swapped the propane and kero inputs so I fed it though propane input. I am not fully sure about that because I disconnected both tubes between while however, I remember I had stuck gas valve on the begin yesterday so I was rewiring some stuff and here most probably swapping of the inputs happened. Quite stupid mistake I know. Today with 100% correct plumbing also the EGT was OK about 500..600 C.

Here my question: because of yesterday’s run completely without lubrication: should I let rebuild the turbine with new bearings? The feeling of the bearings subjectively looks be smooth just as before yesterday’s run without lubrication of bearings.

Thanks much for your advices.

Last edited by CRX Turbines; 08-28-2023 at 06:55 AM.

#8

Junior Member

Join Date: Mar 2019

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

If the run was short then you will more than likely be ok. 780 is not the end of the world. What is the temp at idle? You know that this temp reading is altogether based on how far the temp probe is into the tail cone so if too high pull the probe out a small amount. The temp of the bearings is far lower being at the center and with some air riding along the back of the compressor and down the shaft.

I would try running it and if the problem persists or gets worse then change the bearings but it sounds like you will be ok, If you did by chance do anything wrong, the tail bearing woudl be the one to suffer, not so much the front.

Andy

I would try running it and if the problem persists or gets worse then change the bearings but it sounds like you will be ok, If you did by chance do anything wrong, the tail bearing woudl be the one to suffer, not so much the front.

Andy