JetCat Titan nozzle glowing red at bottom

#1

Below is my vintage JetCat Titan. I removed it from my Eurosport when I did a turbine upgrade. As you will see in the video, it is flaming during spool up, but more scary is that the bottom of the nozzle is getting red hot at idle (both at start and end of video). Don’t remember that ever happening.

Any thoughts why that is happening?

Thanks

Nick

JetCat Turbine-data

---------- INFO Menu ----------

Rest Fuel : 3104

Fuelflow ml/min : 0

BattCnd : -- OK --

LAST RunTime : 106

LAST FuelCount : 229

LAST-OFF PmpVolt : 1.35

LAST-OFF RPM : 53200

LAST-OFF TEMP : 521

LAST-OffCond : Auto-Off

Last MaxTemp : 648

Last MinTemp : 434

Last AvgTemp : 516

Last MaxR AvgTmp : 0

Last StartTemp : 516

Last MaxRPM : 91800

Last MinRPM : 29400

Last AvgRPM : 43700

Last MaxPump : 2.45

Last MinPump : 0.75

Last AvgPump : 1.2

Last FailSafeCnt : 0

Last FailSafeTim : 0

Last MaxAirSpd : 0

Last AvgAirSpd : 0

Last Distance : 0

Last MaxProp : 0

Last MinProp : 0

-------- MIN/MAX Menu -------

MaxPump : 2.45

MaxTemp : 648

AvgPump : 1.2

MaxRpm : 91800

AvgRpm : 19600

MaxProp : 0

-------- STATISTICS Menu -------

Total Run-Time : 166168

Runs OK : 343

Runs aborted : 7

Ignitions OK : 347

Ignitions FAILED : 5

Starts FAILED : 7

Total fuel count : 179378

LoBatt Cut-Outs : 0

-------- LIMITS Menu -------

Minimum RPM : 32000

Maximum RPM : 122000

MaxRPM0 : 48500

MaxRPM1 : 48500

MaxRPM2 : 48500

ShaftHiR0 : 48500

ShaftHiR1 : 48500

ShaftHiR2 : 48500

LowIdle RPM : 32000

PitchServo Revrs : DISABLED

Pitch negative : 0

Pitch zero : 18420

Pitch max : 12343

Pitch sail : 17217

Pitch Reg-Kp : 0

Pitch Reg-Ki : 21474833.49

Pitch LimTemp : 0

Ignition-Mode : KEROSENE

Battery Type : NiCd

LowBatt. Warning : DISABLED

Fueltank size : 4000

LowFuel Limit : 400

LowFuel Warning : DISABLED

GlowPlug Power : 2.34

Gas flow % : 80

AUX-channel func : ON; TrbCtrl ON

FailSafe delay : 0.1

FailSafeTimeOut : 2

FailSafeRPM : 50000

Drain Gastank : DISABLED

SpoolUp Time : 4

AUX-ch SmokeCtrl : DISABLED

Smoker WarnFunct : DISABLED

IdleThrResponse : Fast

FullThrResponse : Fast

GPS-Receiver : DISABLED

AirSpeed units : mph

StartUp Mode : SEQUENCE

Time Rpm SetRpm Temp Pump State THR AUX Batt AirSpd SetSpd

517 3400 0 223 0.00 8 100 0 9.79 0 0

599 1270 3000 86 0.32 16 100 50 9.22 0 0

601 1890 3000 85 0.32 16 100 50 9.15 0 0

602 2320 3000 84 0.32 16 100 50 9.11 0 0

602 2650 3000 84 0.32 2 100 50 9.07 0 0

604 2940 3000 82 0.32 2 100 50 9.01 0 0

604 3110 3000 81 0.32 2 100 50 8.97 0 0

606 3290 3000 82 0.32 2 100 50 8.93 0 0

607 3430 3000 84 0.32 2 100 50 8.90 0 0

608 3540 3000 88 0.32 2 100 50 8.87 0 0

609 3670 3000 96 0.32 17 100 50 8.85 0 0

610 3820 4110 106 0.39 19 100 50 8.82 0 0

611 4090 4750 115 0.40 19 100 50 8.78 0 0

612 4460 5400 127 0.41 19 100 50 8.75 0 0

613 4880 6050 138 0.41 19 100 50 8.72 0 0

614 5360 6690 150 0.42 19 100 50 8.71 0 0

615 6070 7340 163 0.43 19 100 50 8.82 0 0

616 6660 7990 178 0.44 19 100 50 8.93 0 0

617 7170 8630 191 0.45 19 100 50 9.01 0 0

618 7620 9280 203 0.46 19 100 50 9.08 0 0

619 8030 9930 213 0.47 19 100 50 9.14 0 0

620 8450 10830 225 0.47 19 100 50 9.18 0 0

621 9010 32500 236 0.48 3 100 50 9.20 0 0

622 9970 32500 247 0.50 3 100 50 9.18 0 0

623 10840 32500 258 0.52 3 100 50 9.15 0 0

624 11660 32500 268 0.54 3 100 50 9.12 0 0

624 12270 32500 277 0.54 3 100 50 9.10 0 0

625 13170 32500 288 0.57 3 100 50 9.08 0 0

627 13930 32500 299 0.60 3 100 50 9.07 0 0

628 14620 32500 311 0.62 3 100 50 9.06 0 0

629 15500 32500 323 0.65 3 100 50 9.04 0 0

630 16440 32500 334 0.68 3 100 50 9.03 0 0

631 17230 32500 345 0.71 3 100 50 9.02 0 0

632 18200 32500 359 0.74 3 100 50 9.01 0 0

633 19350 32500 373 0.74 3 100 50 8.99 0 0

634 20390 32500 383 0.74 3 100 50 8.99 0 0

634 21290 32500 392 0.76 3 100 50 8.98 0 0

636 22310 32500 400 0.79 3 100 50 8.97 0 0

637 23160 32500 406 0.83 3 100 50 8.96 0 0

638 24030 32500 409 0.86 3 100 50 8.95 0 0

639 24840 32500 415 0.89 3 100 50 8.95 0 0

640 25650 32500 422 0.91 3 100 50 8.94 0 0

641 26120 32500 427 0.95 3 100 50 9.01 0 0

642 26120 32500 433 0.98 3 100 50 9.12 0 0

643 26370 32500 442 1.02 3 100 50 9.22 0 0

643 26670 32500 450 1.04 3 100 50 9.30 0 0

645 27220 32500 458 1.09 3 100 50 9.37 0 0

646 27700 32500 467 1.13 3 100 50 9.43 0 0

647 28360 32500 477 1.17 3 100 50 9.48 0 0

648 29290 32500 485 1.17 3 100 50 9.52 0 0

649 30030 32500 487 1.17 3 100 50 9.55 0 0

650 31070 32500 490 1.17 3 100 50 9.58 0 0

651 32250 32500 493 1.17 3 100 50 9.61 0 0

652 35080 52000 495 1.30 4 100 50 9.63 0 0

653 39300 52000 503 1.41 4 100 50 9.65 0 0

654 46560 52000 513 1.48 4 100 50 9.67 0 0

655 56630 52000 519 1.42 4 100 50 9.68 0 0

656 55520 52000 503 1.34 4 100 50 9.69 0 0

657 50020 50000 484 1.35 6 100 50 9.70 0 0

658 48410 40000 477 1.25 6 100 50 9.71 0 0

658 46960 32000 476 1.09 6 100 50 9.72 0 0

660 41910 32000 469 0.97 6 100 50 9.73 0 0

661 37740 32000 460 0.93 6 100 50 9.74 0 0

662 34640 32000 458 0.91 6 100 50 9.74 0 0

663 32820 32000 460 0.91 6 100 50 9.75 0 0

664 31790 32000 464 0.91 6 100 50 9.76 0 0

665 30850 32000 469 0.92 6 100 50 9.76 0 0

666 30190 32000 475 0.92 6 100 50 9.77 0 0

667 30190 32000 483 0.93 6 100 50 9.77 0 0

668 30510 32000 492 0.94 6 100 50 9.77 0 0

669 30670 32000 497 0.95 6 100 50 9.78 0 0

670 30980 32000 502 0.95 6 100 50 9.78 0 0

671 31330 32000 506 0.96 6 100 50 9.79 0 0

672 31610 32000 509 0.96 6 100 50 9.79 0 0

673 31790 32000 513 0.96 6 100 50 9.79 0 0

674 32130 32000 515 0.96 6 100 50 9.79 0 0

675 32500 32000 516 0.96 6 100 50 9.79 0 0

676 32800 32000 517 0.95 6 100 50 9.79 0 0

677 33140 32000 517 0.95 6 100 50 9.80 0 0

678 33310 32000 517 0.94 6 100 50 9.80 0 0

679 33190 32000 512 0.93 6 100 50 9.80 0 0

680 33050 32000 510 0.93 6 100 50 9.80 0 0

681 32920 31990 515 0.92 11 20 50 9.81 0 0

682 32720 31990 515 0.92 11 20 50 9.80 0 0

683 32760 31990 519 0.91 11 20 50 9.81 0 0

684 31790 31990 514 0.91 11 20 50 9.81 0 0

685 30170 31990 504 0.92 11 20 50 9.81 0 0

686 29040 31990 501 0.93 11 20 50 9.81 0 0

687 28090 72270 501 1.03 11 44 50 9.81 0 0

688 27690 72270 504 1.20 11 44 50 9.81 0 0

689 28280 72270 513 1.44 11 44 50 9.81 0 0

690 29280 72270 533 1.65 11 44 50 9.80 0 0

691 30260 72270 552 1.72 11 44 50 9.80 0 0

692 32090 72270 576 1.74 11 44 50 9.80 0 0

693 38040 72270 633 1.83 11 44 50 9.79 0 0

694 50350 72270 674 2.03 11 44 50 9.79 0 0

695 75620 72790 699 2.09 11 45 50 9.79 0 0

696 73930 91460 641 2.33 11 62 50 9.78 0 0

697 89730 117420 598 3.12 11 93 50 9.77 0 0

698 109200 122000 599 3.90 11 100 50 9.75 0 0

699 120400 122000 598 4.19 11 100 50 9.73 0 0

700 123930 122000 621 4.06 11 100 50 9.70 0 0

701 123700 122000 634 3.93 11 100 50 9.69 0 0

702 123020 122000 630 3.83 11 100 50 9.67 0 0

703 122880 122000 621 3.76 11 100 50 9.66 0 0

705 122160 122000 613 3.74 11 100 50 9.65 0 0

706 98200 31990 579 1.27 11 20 50 9.66 0 0

707 65250 31990 505 0.86 11 20 50 9.68 0 0

708 49460 31990 472 0.72 11 20 50 9.70 0 0

709 40160 31990 464 0.69 11 20 50 9.72 0 0

710 35240 31990 466 0.71 11 20 50 9.73 0 0

711 33270 31990 473 0.71 11 20 50 9.75 0 0

712 31800 31990 480 0.71 11 20 50 9.76 0 0

713 30910 31990 486 0.71 11 20 50 9.77 0 0

714 30240 31990 491 0.72 11 20 50 9.77 0 0

715 29790 31990 496 0.73 11 20 50 9.78 0 0

716 29620 31990 500 0.74 11 20 50 9.79 0 0

717 29950 31990 504 0.75 11 20 50 9.79 0 0

718 30020 31990 505 0.76 11 20 50 9.80 0 0

719 30040 31990 505 0.77 11 20 50 9.80 0 0

720 30320 31990 508 0.78 11 20 50 9.80 0 0

721 30380 31990 508 0.79 11 20 50 9.80 0 0

722 30450 31990 508 0.80 11 20 50 9.81 0 0

723 30630 31990 510 0.80 11 20 50 9.81 0 0

724 30450 31990 512 0.81 11 20 50 9.81 0 0

725 30340 31990 511 0.82 11 20 50 9.81 0 0

726 30320 31990 511 0.82 11 20 50 9.81 0 0

727 30570 31990 511 0.83 11 20 50 9.81 0 0

728 30740 31990 512 0.84 11 20 50 9.81 0 0

729 30900 31990 513 0.84 11 20 50 9.81 0 0

730 30850 31990 513 0.85 11 20 50 9.82 0 0

731 30850 31990 514 0.85 11 20 50 9.82 0 0

732 30870 31990 516 0.86 11 20 50 9.82 0 0

733 30970 31990 519 0.87 11 20 50 9.82 0 0

734 31050 31990 523 0.87 11 20 50 9.82 0 0

735 31170 31990 525 0.87 11 20 50 9.82 0 0

736 31170 31990 525 0.88 11 20 50 9.82 0 0

737 31170 31990 525 0.88 11 20 50 9.82 0 0

738 31320 31990 528 0.89 11 20 50 9.82 0 0

739 31440 31990 530 0.89 11 20 50 9.82 0 0

740 31930 31990 538 0.89 11 20 50 9.82 0 0

741 32170 31990 543 0.89 11 20 50 9.82 0 0

742 32170 31990 546 0.89 11 20 50 9.82 0 0

743 32190 31990 548 0.89 11 20 50 9.82 0 0

744 32150 31990 547 0.89 11 20 50 9.82 0 0

745 32150 31990 548 0.89 11 20 50 9.82 0 0

746 31770 52000 550 0.89 10 20 100 9.82 0 0

747 31730 52000 552 0.95 10 20 100 9.82 0 0

748 31750 52000 557 1.08 10 20 100 9.82 0 0

749 32330 52000 556 1.35 10 20 100 9.82 0 0

750 34720 52000 564 1.35 10 20 100 9.82 0 0

751 38610 52000 569 1.35 10 20 100 9.82 0 0

752 44640 52000 564 1.35 10 20 100 9.81 0 0

753 51200 52000 562 1.35 10 20 100 9.81 0 0

754 55560 52000 564 1.35 10 20 100 9.81 0 0

755 54700 0 555 0.00 8 20 100 9.81 0 0

756 26190 0 473 0.00 8 20 0 9.82 0 0

757 16970 0 405 0.00 8 20 0 9.83 0 0

758 12120 0 373 0.00 8 20 0 9.84 0 0

Any thoughts why that is happening?

Thanks

Nick

JetCat Turbine-data

---------- INFO Menu ----------

Rest Fuel : 3104

Fuelflow ml/min : 0

BattCnd : -- OK --

LAST RunTime : 106

LAST FuelCount : 229

LAST-OFF PmpVolt : 1.35

LAST-OFF RPM : 53200

LAST-OFF TEMP : 521

LAST-OffCond : Auto-Off

Last MaxTemp : 648

Last MinTemp : 434

Last AvgTemp : 516

Last MaxR AvgTmp : 0

Last StartTemp : 516

Last MaxRPM : 91800

Last MinRPM : 29400

Last AvgRPM : 43700

Last MaxPump : 2.45

Last MinPump : 0.75

Last AvgPump : 1.2

Last FailSafeCnt : 0

Last FailSafeTim : 0

Last MaxAirSpd : 0

Last AvgAirSpd : 0

Last Distance : 0

Last MaxProp : 0

Last MinProp : 0

-------- MIN/MAX Menu -------

MaxPump : 2.45

MaxTemp : 648

AvgPump : 1.2

MaxRpm : 91800

AvgRpm : 19600

MaxProp : 0

-------- STATISTICS Menu -------

Total Run-Time : 166168

Runs OK : 343

Runs aborted : 7

Ignitions OK : 347

Ignitions FAILED : 5

Starts FAILED : 7

Total fuel count : 179378

LoBatt Cut-Outs : 0

-------- LIMITS Menu -------

Minimum RPM : 32000

Maximum RPM : 122000

MaxRPM0 : 48500

MaxRPM1 : 48500

MaxRPM2 : 48500

ShaftHiR0 : 48500

ShaftHiR1 : 48500

ShaftHiR2 : 48500

LowIdle RPM : 32000

PitchServo Revrs : DISABLED

Pitch negative : 0

Pitch zero : 18420

Pitch max : 12343

Pitch sail : 17217

Pitch Reg-Kp : 0

Pitch Reg-Ki : 21474833.49

Pitch LimTemp : 0

Ignition-Mode : KEROSENE

Battery Type : NiCd

LowBatt. Warning : DISABLED

Fueltank size : 4000

LowFuel Limit : 400

LowFuel Warning : DISABLED

GlowPlug Power : 2.34

Gas flow % : 80

AUX-channel func : ON; TrbCtrl ON

FailSafe delay : 0.1

FailSafeTimeOut : 2

FailSafeRPM : 50000

Drain Gastank : DISABLED

SpoolUp Time : 4

AUX-ch SmokeCtrl : DISABLED

Smoker WarnFunct : DISABLED

IdleThrResponse : Fast

FullThrResponse : Fast

GPS-Receiver : DISABLED

AirSpeed units : mph

StartUp Mode : SEQUENCE

Time Rpm SetRpm Temp Pump State THR AUX Batt AirSpd SetSpd

517 3400 0 223 0.00 8 100 0 9.79 0 0

599 1270 3000 86 0.32 16 100 50 9.22 0 0

601 1890 3000 85 0.32 16 100 50 9.15 0 0

602 2320 3000 84 0.32 16 100 50 9.11 0 0

602 2650 3000 84 0.32 2 100 50 9.07 0 0

604 2940 3000 82 0.32 2 100 50 9.01 0 0

604 3110 3000 81 0.32 2 100 50 8.97 0 0

606 3290 3000 82 0.32 2 100 50 8.93 0 0

607 3430 3000 84 0.32 2 100 50 8.90 0 0

608 3540 3000 88 0.32 2 100 50 8.87 0 0

609 3670 3000 96 0.32 17 100 50 8.85 0 0

610 3820 4110 106 0.39 19 100 50 8.82 0 0

611 4090 4750 115 0.40 19 100 50 8.78 0 0

612 4460 5400 127 0.41 19 100 50 8.75 0 0

613 4880 6050 138 0.41 19 100 50 8.72 0 0

614 5360 6690 150 0.42 19 100 50 8.71 0 0

615 6070 7340 163 0.43 19 100 50 8.82 0 0

616 6660 7990 178 0.44 19 100 50 8.93 0 0

617 7170 8630 191 0.45 19 100 50 9.01 0 0

618 7620 9280 203 0.46 19 100 50 9.08 0 0

619 8030 9930 213 0.47 19 100 50 9.14 0 0

620 8450 10830 225 0.47 19 100 50 9.18 0 0

621 9010 32500 236 0.48 3 100 50 9.20 0 0

622 9970 32500 247 0.50 3 100 50 9.18 0 0

623 10840 32500 258 0.52 3 100 50 9.15 0 0

624 11660 32500 268 0.54 3 100 50 9.12 0 0

624 12270 32500 277 0.54 3 100 50 9.10 0 0

625 13170 32500 288 0.57 3 100 50 9.08 0 0

627 13930 32500 299 0.60 3 100 50 9.07 0 0

628 14620 32500 311 0.62 3 100 50 9.06 0 0

629 15500 32500 323 0.65 3 100 50 9.04 0 0

630 16440 32500 334 0.68 3 100 50 9.03 0 0

631 17230 32500 345 0.71 3 100 50 9.02 0 0

632 18200 32500 359 0.74 3 100 50 9.01 0 0

633 19350 32500 373 0.74 3 100 50 8.99 0 0

634 20390 32500 383 0.74 3 100 50 8.99 0 0

634 21290 32500 392 0.76 3 100 50 8.98 0 0

636 22310 32500 400 0.79 3 100 50 8.97 0 0

637 23160 32500 406 0.83 3 100 50 8.96 0 0

638 24030 32500 409 0.86 3 100 50 8.95 0 0

639 24840 32500 415 0.89 3 100 50 8.95 0 0

640 25650 32500 422 0.91 3 100 50 8.94 0 0

641 26120 32500 427 0.95 3 100 50 9.01 0 0

642 26120 32500 433 0.98 3 100 50 9.12 0 0

643 26370 32500 442 1.02 3 100 50 9.22 0 0

643 26670 32500 450 1.04 3 100 50 9.30 0 0

645 27220 32500 458 1.09 3 100 50 9.37 0 0

646 27700 32500 467 1.13 3 100 50 9.43 0 0

647 28360 32500 477 1.17 3 100 50 9.48 0 0

648 29290 32500 485 1.17 3 100 50 9.52 0 0

649 30030 32500 487 1.17 3 100 50 9.55 0 0

650 31070 32500 490 1.17 3 100 50 9.58 0 0

651 32250 32500 493 1.17 3 100 50 9.61 0 0

652 35080 52000 495 1.30 4 100 50 9.63 0 0

653 39300 52000 503 1.41 4 100 50 9.65 0 0

654 46560 52000 513 1.48 4 100 50 9.67 0 0

655 56630 52000 519 1.42 4 100 50 9.68 0 0

656 55520 52000 503 1.34 4 100 50 9.69 0 0

657 50020 50000 484 1.35 6 100 50 9.70 0 0

658 48410 40000 477 1.25 6 100 50 9.71 0 0

658 46960 32000 476 1.09 6 100 50 9.72 0 0

660 41910 32000 469 0.97 6 100 50 9.73 0 0

661 37740 32000 460 0.93 6 100 50 9.74 0 0

662 34640 32000 458 0.91 6 100 50 9.74 0 0

663 32820 32000 460 0.91 6 100 50 9.75 0 0

664 31790 32000 464 0.91 6 100 50 9.76 0 0

665 30850 32000 469 0.92 6 100 50 9.76 0 0

666 30190 32000 475 0.92 6 100 50 9.77 0 0

667 30190 32000 483 0.93 6 100 50 9.77 0 0

668 30510 32000 492 0.94 6 100 50 9.77 0 0

669 30670 32000 497 0.95 6 100 50 9.78 0 0

670 30980 32000 502 0.95 6 100 50 9.78 0 0

671 31330 32000 506 0.96 6 100 50 9.79 0 0

672 31610 32000 509 0.96 6 100 50 9.79 0 0

673 31790 32000 513 0.96 6 100 50 9.79 0 0

674 32130 32000 515 0.96 6 100 50 9.79 0 0

675 32500 32000 516 0.96 6 100 50 9.79 0 0

676 32800 32000 517 0.95 6 100 50 9.79 0 0

677 33140 32000 517 0.95 6 100 50 9.80 0 0

678 33310 32000 517 0.94 6 100 50 9.80 0 0

679 33190 32000 512 0.93 6 100 50 9.80 0 0

680 33050 32000 510 0.93 6 100 50 9.80 0 0

681 32920 31990 515 0.92 11 20 50 9.81 0 0

682 32720 31990 515 0.92 11 20 50 9.80 0 0

683 32760 31990 519 0.91 11 20 50 9.81 0 0

684 31790 31990 514 0.91 11 20 50 9.81 0 0

685 30170 31990 504 0.92 11 20 50 9.81 0 0

686 29040 31990 501 0.93 11 20 50 9.81 0 0

687 28090 72270 501 1.03 11 44 50 9.81 0 0

688 27690 72270 504 1.20 11 44 50 9.81 0 0

689 28280 72270 513 1.44 11 44 50 9.81 0 0

690 29280 72270 533 1.65 11 44 50 9.80 0 0

691 30260 72270 552 1.72 11 44 50 9.80 0 0

692 32090 72270 576 1.74 11 44 50 9.80 0 0

693 38040 72270 633 1.83 11 44 50 9.79 0 0

694 50350 72270 674 2.03 11 44 50 9.79 0 0

695 75620 72790 699 2.09 11 45 50 9.79 0 0

696 73930 91460 641 2.33 11 62 50 9.78 0 0

697 89730 117420 598 3.12 11 93 50 9.77 0 0

698 109200 122000 599 3.90 11 100 50 9.75 0 0

699 120400 122000 598 4.19 11 100 50 9.73 0 0

700 123930 122000 621 4.06 11 100 50 9.70 0 0

701 123700 122000 634 3.93 11 100 50 9.69 0 0

702 123020 122000 630 3.83 11 100 50 9.67 0 0

703 122880 122000 621 3.76 11 100 50 9.66 0 0

705 122160 122000 613 3.74 11 100 50 9.65 0 0

706 98200 31990 579 1.27 11 20 50 9.66 0 0

707 65250 31990 505 0.86 11 20 50 9.68 0 0

708 49460 31990 472 0.72 11 20 50 9.70 0 0

709 40160 31990 464 0.69 11 20 50 9.72 0 0

710 35240 31990 466 0.71 11 20 50 9.73 0 0

711 33270 31990 473 0.71 11 20 50 9.75 0 0

712 31800 31990 480 0.71 11 20 50 9.76 0 0

713 30910 31990 486 0.71 11 20 50 9.77 0 0

714 30240 31990 491 0.72 11 20 50 9.77 0 0

715 29790 31990 496 0.73 11 20 50 9.78 0 0

716 29620 31990 500 0.74 11 20 50 9.79 0 0

717 29950 31990 504 0.75 11 20 50 9.79 0 0

718 30020 31990 505 0.76 11 20 50 9.80 0 0

719 30040 31990 505 0.77 11 20 50 9.80 0 0

720 30320 31990 508 0.78 11 20 50 9.80 0 0

721 30380 31990 508 0.79 11 20 50 9.80 0 0

722 30450 31990 508 0.80 11 20 50 9.81 0 0

723 30630 31990 510 0.80 11 20 50 9.81 0 0

724 30450 31990 512 0.81 11 20 50 9.81 0 0

725 30340 31990 511 0.82 11 20 50 9.81 0 0

726 30320 31990 511 0.82 11 20 50 9.81 0 0

727 30570 31990 511 0.83 11 20 50 9.81 0 0

728 30740 31990 512 0.84 11 20 50 9.81 0 0

729 30900 31990 513 0.84 11 20 50 9.81 0 0

730 30850 31990 513 0.85 11 20 50 9.82 0 0

731 30850 31990 514 0.85 11 20 50 9.82 0 0

732 30870 31990 516 0.86 11 20 50 9.82 0 0

733 30970 31990 519 0.87 11 20 50 9.82 0 0

734 31050 31990 523 0.87 11 20 50 9.82 0 0

735 31170 31990 525 0.87 11 20 50 9.82 0 0

736 31170 31990 525 0.88 11 20 50 9.82 0 0

737 31170 31990 525 0.88 11 20 50 9.82 0 0

738 31320 31990 528 0.89 11 20 50 9.82 0 0

739 31440 31990 530 0.89 11 20 50 9.82 0 0

740 31930 31990 538 0.89 11 20 50 9.82 0 0

741 32170 31990 543 0.89 11 20 50 9.82 0 0

742 32170 31990 546 0.89 11 20 50 9.82 0 0

743 32190 31990 548 0.89 11 20 50 9.82 0 0

744 32150 31990 547 0.89 11 20 50 9.82 0 0

745 32150 31990 548 0.89 11 20 50 9.82 0 0

746 31770 52000 550 0.89 10 20 100 9.82 0 0

747 31730 52000 552 0.95 10 20 100 9.82 0 0

748 31750 52000 557 1.08 10 20 100 9.82 0 0

749 32330 52000 556 1.35 10 20 100 9.82 0 0

750 34720 52000 564 1.35 10 20 100 9.82 0 0

751 38610 52000 569 1.35 10 20 100 9.82 0 0

752 44640 52000 564 1.35 10 20 100 9.81 0 0

753 51200 52000 562 1.35 10 20 100 9.81 0 0

754 55560 52000 564 1.35 10 20 100 9.81 0 0

755 54700 0 555 0.00 8 20 100 9.81 0 0

756 26190 0 473 0.00 8 20 0 9.82 0 0

757 16970 0 405 0.00 8 20 0 9.83 0 0

758 12120 0 373 0.00 8 20 0 9.84 0 0

#2

My Feedback: (10)

Just a guess Nick, uneven fuel atomization. Maybe a broken needle.

If a lot of liquid state fuel gets into the turbine during operation, the swirl seems to kick the "liquid fuel" hotspot up to maybe 4-5 o'clock position, looking at the rear. I have rarely seen the bottom (true 6 o'clock) of the nozzle get that hot. My money is broken needle or some sort of leak in the fuel manifold.

If a lot of liquid state fuel gets into the turbine during operation, the swirl seems to kick the "liquid fuel" hotspot up to maybe 4-5 o'clock position, looking at the rear. I have rarely seen the bottom (true 6 o'clock) of the nozzle get that hot. My money is broken needle or some sort of leak in the fuel manifold.

#3

My Feedback: (18)

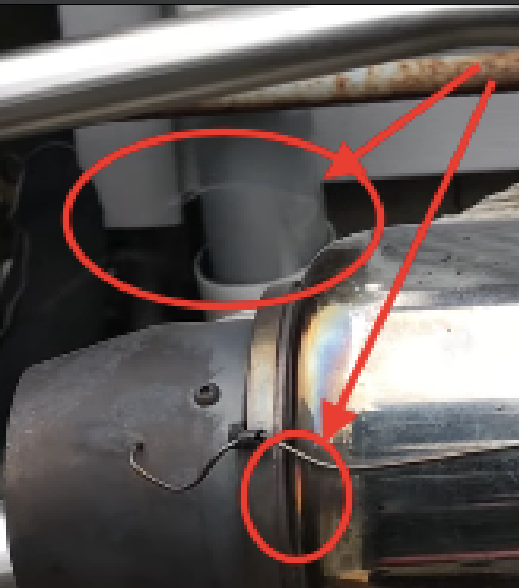

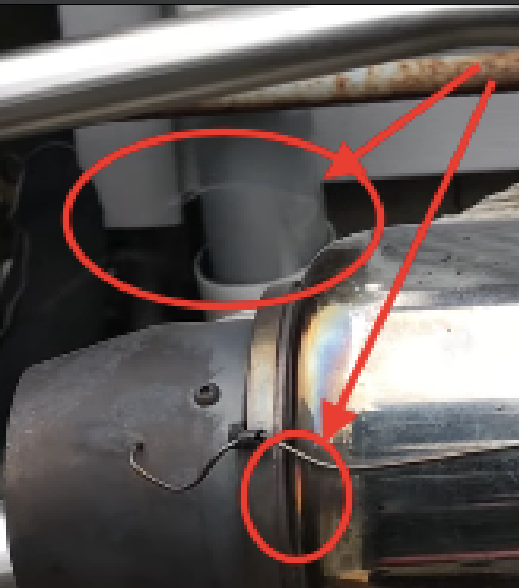

This is a total guess, but It looks like gases are escaping/leaking from between the can and the cone, kind of like an exhaust leak on a header. The base of the can looks like it's getting pretty hot where there are gases leaking. In fact, you can see flames shooting past a gap between the two components. That can't be right. I don't think there is a gasket, have you checked the torque on the cone fasteners?

Last edited by skunkwurk; 12-09-2020 at 01:37 PM.

#4

Just a guess Nick, uneven fuel atomization. Maybe a broken needle.

If a lot of liquid state fuel gets into the turbine during operation, the swirl seems to kick the "liquid fuel" hotspot up to maybe 4-5 o'clock position, looking at the rear. I have rarely seen the bottom (true 6 o'clock) of the nozzle get that hot. My money is broken needle or some sort of leak in the fuel manifold.

If a lot of liquid state fuel gets into the turbine during operation, the swirl seems to kick the "liquid fuel" hotspot up to maybe 4-5 o'clock position, looking at the rear. I have rarely seen the bottom (true 6 o'clock) of the nozzle get that hot. My money is broken needle or some sort of leak in the fuel manifold.

I appreciate your feedback. Makes sense about a broken needle or some sort of leak in the fuel ring to get a hot spot like that. I had just never saw that on any turbine over the many years.

Probably time to retire it! This was the turbine Bob gave me to replace my new P-160 when it "came apart" at Winamac in 2005.... NGV / turbine wheel clearance issues with the new P-160's back then...

Thanks

Nick

#5

This is a total guess, but It looks like gases are escaping/leaking from between the can and the cone, kind of like an exhaust leak on a header. The base of the can looks like it's getting pretty hot where there are gases leaking. In fact, you can see flames shooting past a gap between the two components. That can't be right. I don't think there is a gasket, have you checked the torque on the cone fasteners?

Thanks

Nick

#7

This is a total guess, but It looks like gases are escaping/leaking from between the can and the cone, kind of like an exhaust leak on a header. The base of the can looks like it's getting pretty hot where there are gases leaking. In fact, you can see flames shooting past a gap between the two components. That can't be right. I don't think there is a gasket, have you checked the torque on the cone fasteners?

#8

Any gas turbine engine, large or small, P20 to GE 90, which is not behaving correctly needs to be thoroughly examined by a professional, manufacturer or authorised service agent, not the “experts” on RCU.

That extremely high tailpipe temp. might have led to turbine “creep” which could, in turn, lead to turbine failure.

The consequences of a malfunctioning engine could be dangerous or even catastrophic. Ask GE , P &W or RR, they've all had their serious failures.

That engine is not in good health, even sounds rough after start.

That extremely high tailpipe temp. might have led to turbine “creep” which could, in turn, lead to turbine failure.

The consequences of a malfunctioning engine could be dangerous or even catastrophic. Ask GE , P &W or RR, they've all had their serious failures.

That engine is not in good health, even sounds rough after start.

Last edited by David Gladwin; 12-11-2020 at 02:14 AM.

#9

My Feedback: (18)

Not sure who David is referring to, I don't remember anyone claiming to be an "expert", I too would heed to George's suggestions if I owned this turbine. That said, I was merely pointing out an observation. I don't personally own this turbine (this could be normal, I suppose), but what I can say is that none of my turbines puff smoke like this or can you visibly see flames in a gap between the can and the cone. Gases appear to be escaping, which could pose a danger if installed in a model. That obviously goes without saying. Re-play it back slowly, you'll see what I mean.

Last edited by skunkwurk; 12-11-2020 at 09:34 AM.

#10

George:

You were correct in your assumption; the kero plug startup valve solenoid was partially or fully stuck open after startup and was feeding excess fuel into the turbine. Once started and in Stabilize mode, I turned off the manual valve in the kero startup line and the hot spot on the nozzle never showed up (see short video). Restarted multiple times with same procedure and no hot spot. Also compared data from runs from 10 years ago to this latest run and had very similar numbers (except my fuel pump and / or filter may need attention / replacement).

Before you “fixed” it George, I was going to drop the Titan off to you when we went to visit my wife’s relatives in VA Beach for Christmas. But the COVID thing is keeping us in Ohio this year….

Thanks again, George. Hopefully I will see you at one of the jet rallies next year. Stay well……

David: I hear what you are saying and may still have George "service" it in the future....

Nick

Titan 2nd Run with manual shut-off valve in kero plug start fuel line.

You were correct in your assumption; the kero plug startup valve solenoid was partially or fully stuck open after startup and was feeding excess fuel into the turbine. Once started and in Stabilize mode, I turned off the manual valve in the kero startup line and the hot spot on the nozzle never showed up (see short video). Restarted multiple times with same procedure and no hot spot. Also compared data from runs from 10 years ago to this latest run and had very similar numbers (except my fuel pump and / or filter may need attention / replacement).

Before you “fixed” it George, I was going to drop the Titan off to you when we went to visit my wife’s relatives in VA Beach for Christmas. But the COVID thing is keeping us in Ohio this year….

Thanks again, George. Hopefully I will see you at one of the jet rallies next year. Stay well……

David: I hear what you are saying and may still have George "service" it in the future....

Nick

Titan 2nd Run with manual shut-off valve in kero plug start fuel line.

Last edited by Nick Yuhasz; 12-11-2020 at 03:43 PM.

#12

Glad you sorted it but after an extreme and repeated overtemp. personally I would have it checked. There may even be internal damage which can’t be seen by external inspection and which could lead to a severe failure.

The cause of the overtemp. Has been identified but the possible consequences are unknown.

To quote from Klaus Hunecke,s excellent book, “ Jet Engines“. Creep is that tendency of a material to undergo permanent deformation when subjected to extreme thermal and mechanical stress, finally ending in catastrophic failure. As I suggested was possible.

I have experienced a turbine disc failure, it wasn’t pretty !

I’ll leave it at that and get back to my morning coffee and leave Skunkworks laughing !

The cause of the overtemp. Has been identified but the possible consequences are unknown.

To quote from Klaus Hunecke,s excellent book, “ Jet Engines“. Creep is that tendency of a material to undergo permanent deformation when subjected to extreme thermal and mechanical stress, finally ending in catastrophic failure. As I suggested was possible.

I have experienced a turbine disc failure, it wasn’t pretty !

I’ll leave it at that and get back to my morning coffee and leave Skunkworks laughing !

Last edited by David Gladwin; 12-12-2020 at 02:14 AM.