UMS Gas Radial Engine Enthusiasts Rabbit Hole

#301

Well I finally think the bugs are worked out on the 7-50 and it's ready to be mounted on my 30cc Ultra Stick.

Hopefully this link works , this was recorded today.

https://youtu.be/QBet_BA9ffc

Hopefully this link works , this was recorded today.

https://youtu.be/QBet_BA9ffc

Aaron-

#302

Nice Jason. I like it. Never heard of that material before. Yeah I don't think you'll ever get above 260° LOL. The factory mount on the UMS engines is sort of clunky compared to our Moki mount. But it is solid nonetheless. The Waco ARF I have mine bolted to is a really nice fit.. I think you are on track for the Mamba placement. Do you intend to cant on the thrust line?

Last edited by Hyjinx; 04-16-2024 at 07:34 AM.

#303

Member

My Feedback: (1)

I bought my 50cc to put in a Phoenix 20cc Corsair. I plan on putting a single cylinder engine of equal power or slightly less than the 7-50 for the maiden and first couple of flights. I don't want to take any chances on crashing with such an expensive engine on an untested airframe.

#304

I bought my 50cc to put in a Phoenix 20cc Corsair. I plan on putting a single cylinder engine of equal power or slightly less than the 7-50 for the maiden and first couple of flights. I don't want to take any chances on crashing with such an expensive engine on an untested airframe.

#305

so, i have a ums 5-55 installed in a maxford an-2. broke it in according to the plan, flew about 10? flights so far. 102"WS, approx 20lb FW.

.

there is a quirk, i've noticed recently, that causes the engine to run poorly, quit, and/or be hard to start - STICKY EXHAUST VALVES.

the problem became apparent when i forgot to add seafoam to the new gas mix (40:1 gas il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.

il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.

it affected the top 3 cylinders - the bottom 2 had no issues, but the plugs were wet.

symptom: 1st flight saw engine fade after about 7minutes in the air. engine quit when throttling down for landing. cooled down before 2nd flight, but wouldn't start. #1 cylinder exhaust pushrod fell out. i felt the valve action, by hand, and noticed the valve extremely slow.

i may still have some engine tuning to do (top plug is black and bottom 2 are wet), not sure if this will cure the sticky valves. this just happened on one of my recent flights (with new, non-seafoam gas), but i wasn't aware to check for any stickiness on the previous flights, so not sure about persistence yet.

i also added some baffles, so not sure if there is any contribution to the problem from that. my telemetry says the cylinders are at about 150-160degress (IIRC), but that's all a factor of sensor placement and accuracy, so FWIW.

.

my purpose, with this post, is to let everyone know to check for this when/if you start experiencing rough running or quitting. i know other things could be the cause, but this seems easy to overlook.

.

yeah, i know tom already knows this. ;>/

.

.

there is a quirk, i've noticed recently, that causes the engine to run poorly, quit, and/or be hard to start - STICKY EXHAUST VALVES.

the problem became apparent when i forgot to add seafoam to the new gas mix (40:1 gas

il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.

il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.it affected the top 3 cylinders - the bottom 2 had no issues, but the plugs were wet.

symptom: 1st flight saw engine fade after about 7minutes in the air. engine quit when throttling down for landing. cooled down before 2nd flight, but wouldn't start. #1 cylinder exhaust pushrod fell out. i felt the valve action, by hand, and noticed the valve extremely slow.

i may still have some engine tuning to do (top plug is black and bottom 2 are wet), not sure if this will cure the sticky valves. this just happened on one of my recent flights (with new, non-seafoam gas), but i wasn't aware to check for any stickiness on the previous flights, so not sure about persistence yet.

i also added some baffles, so not sure if there is any contribution to the problem from that. my telemetry says the cylinders are at about 150-160degress (IIRC), but that's all a factor of sensor placement and accuracy, so FWIW.

.

my purpose, with this post, is to let everyone know to check for this when/if you start experiencing rough running or quitting. i know other things could be the cause, but this seems easy to overlook.

.

yeah, i know tom already knows this. ;>/

.

The following users liked this post:

JRSmith (05-21-2024)

#307

My Feedback: (47)

so, i have a ums 5-55 installed in a maxford an-2. broke it in according to the plan, flew about 10? flights so far. 102"WS, approx 20lb FW.

.

there is a quirk, i've noticed recently, that causes the engine to run poorly, quit, and/or be hard to start - STICKY EXHAUST VALVES.

the problem became apparent when i forgot to add seafoam to the new gas mix (40:1 gas il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.

il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.

it affected the top 3 cylinders - the bottom 2 had no issues, but the plugs were wet.

symptom: 1st flight saw engine fade after about 7minutes in the air. engine quit when throttling down for landing. cooled down before 2nd flight, but wouldn't start. #1 cylinder exhaust pushrod fell out. i felt the valve action, by hand, and noticed the valve extremely slow.

i may still have some engine tuning to do (top plug is black and bottom 2 are wet), not sure if this will cure the sticky valves. this just happened on one of my recent flights (with new, non-seafoam gas), but i wasn't aware to check for any stickiness on the previous flights, so not sure about persistence yet.

i also added some baffles, so not sure if there is any contribution to the problem from that. my telemetry says the cylinders are at about 150-160degress (IIRC), but that's all a factor of sensor placement and accuracy, so FWIW.

.

my purpose, with this post, is to let everyone know to check for this when/if you start experiencing rough running or quitting. i know other things could be the cause, but this seems easy to overlook.

.

yeah, i know tom already knows this. ;>/

.

.

there is a quirk, i've noticed recently, that causes the engine to run poorly, quit, and/or be hard to start - STICKY EXHAUST VALVES.

the problem became apparent when i forgot to add seafoam to the new gas mix (40:1 gas

il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.

il). i added a couple oz of seafoam/gallon, and the problem went away -mostly.it affected the top 3 cylinders - the bottom 2 had no issues, but the plugs were wet.

symptom: 1st flight saw engine fade after about 7minutes in the air. engine quit when throttling down for landing. cooled down before 2nd flight, but wouldn't start. #1 cylinder exhaust pushrod fell out. i felt the valve action, by hand, and noticed the valve extremely slow.

i may still have some engine tuning to do (top plug is black and bottom 2 are wet), not sure if this will cure the sticky valves. this just happened on one of my recent flights (with new, non-seafoam gas), but i wasn't aware to check for any stickiness on the previous flights, so not sure about persistence yet.

i also added some baffles, so not sure if there is any contribution to the problem from that. my telemetry says the cylinders are at about 150-160degress (IIRC), but that's all a factor of sensor placement and accuracy, so FWIW.

.

my purpose, with this post, is to let everyone know to check for this when/if you start experiencing rough running or quitting. i know other things could be the cause, but this seems easy to overlook.

.

yeah, i know tom already knows this. ;>/

.

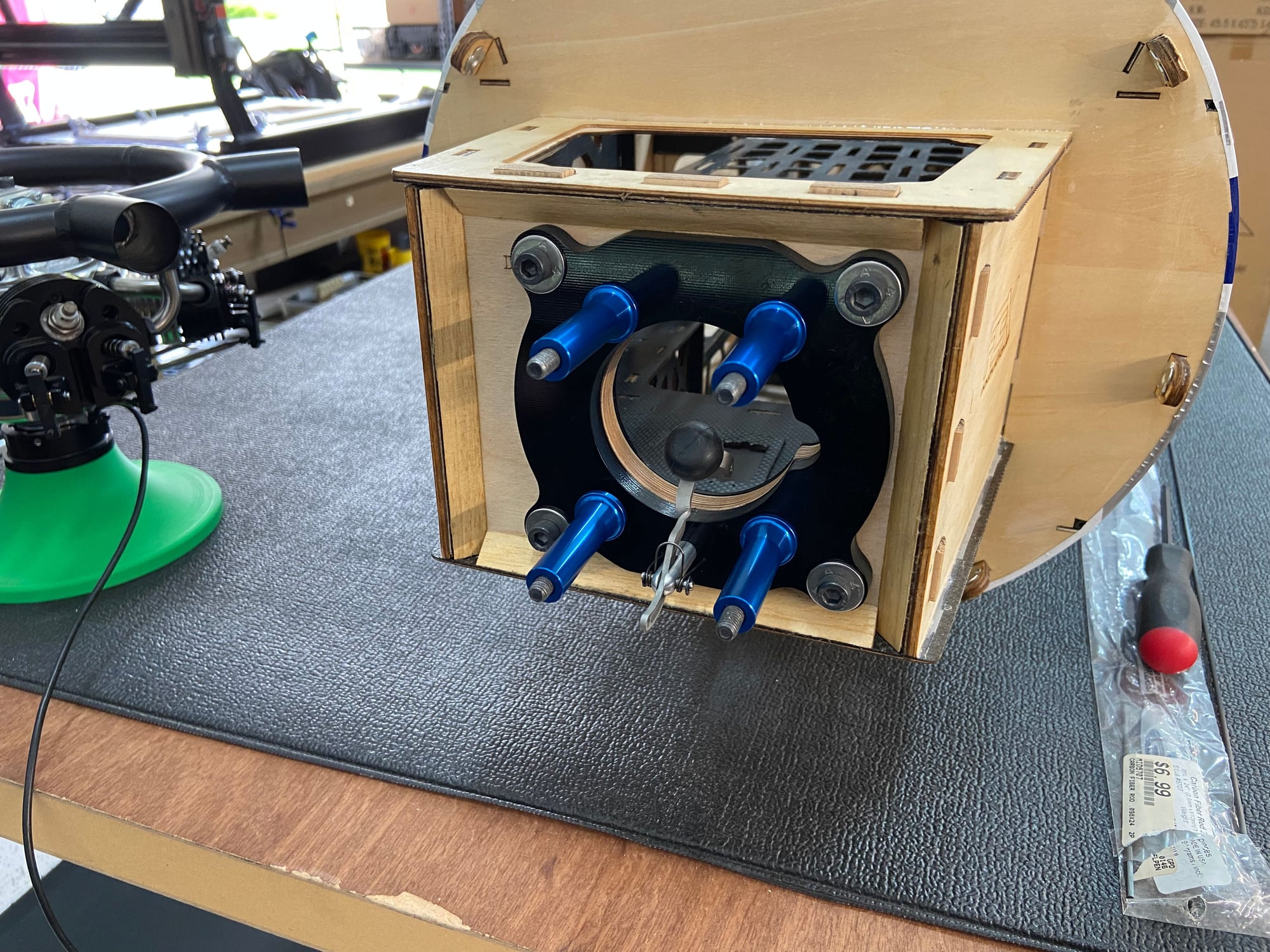

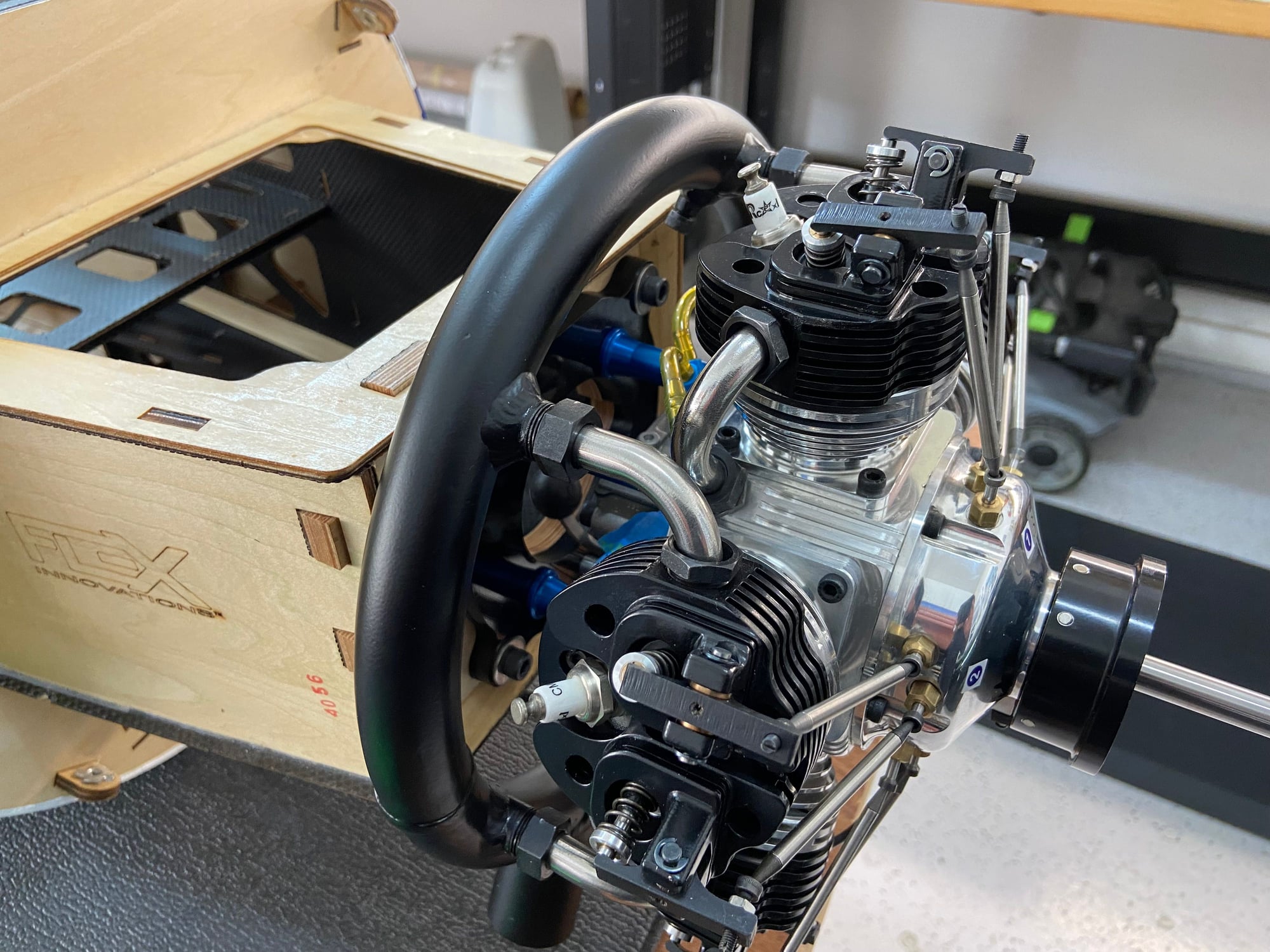

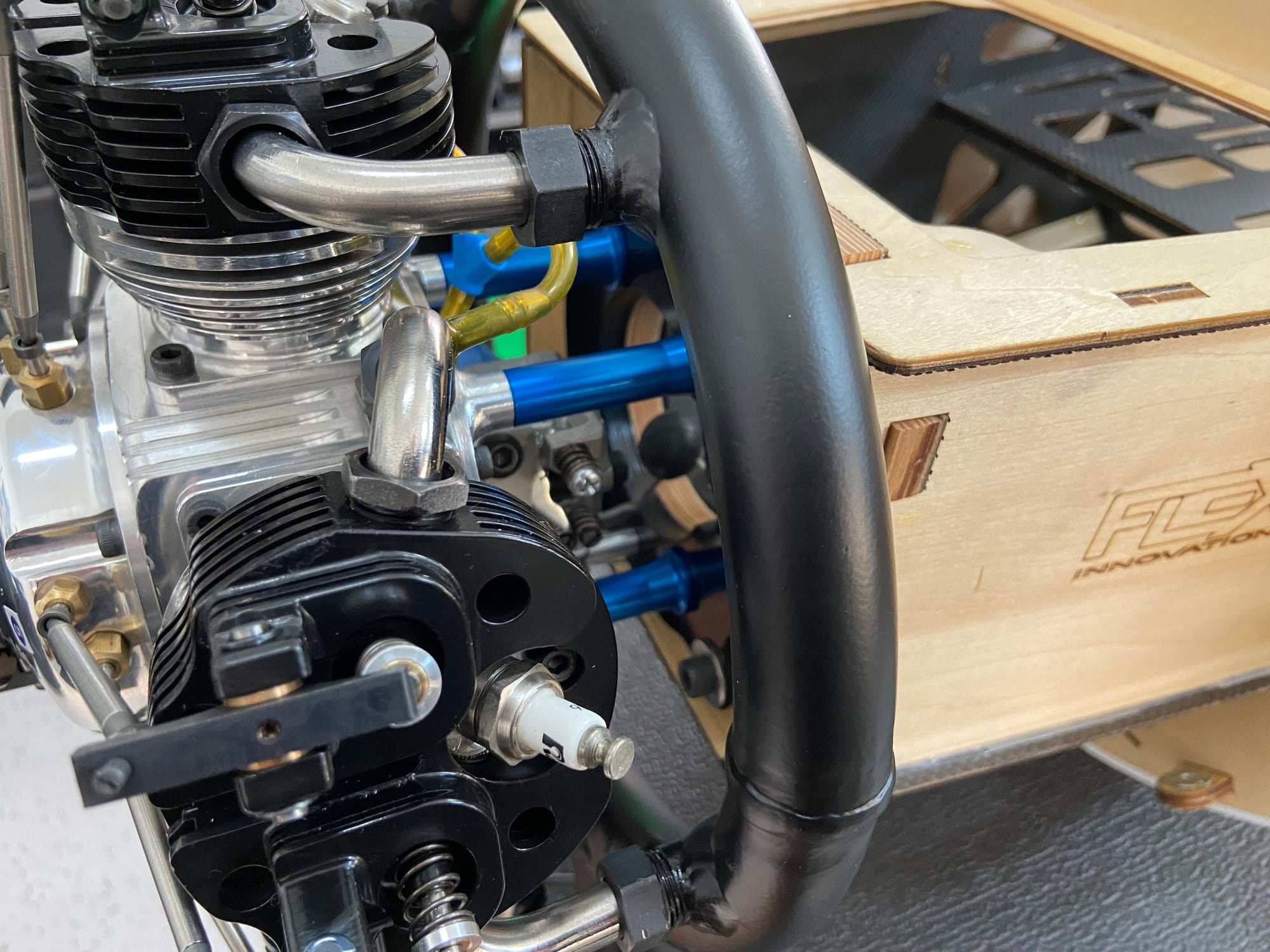

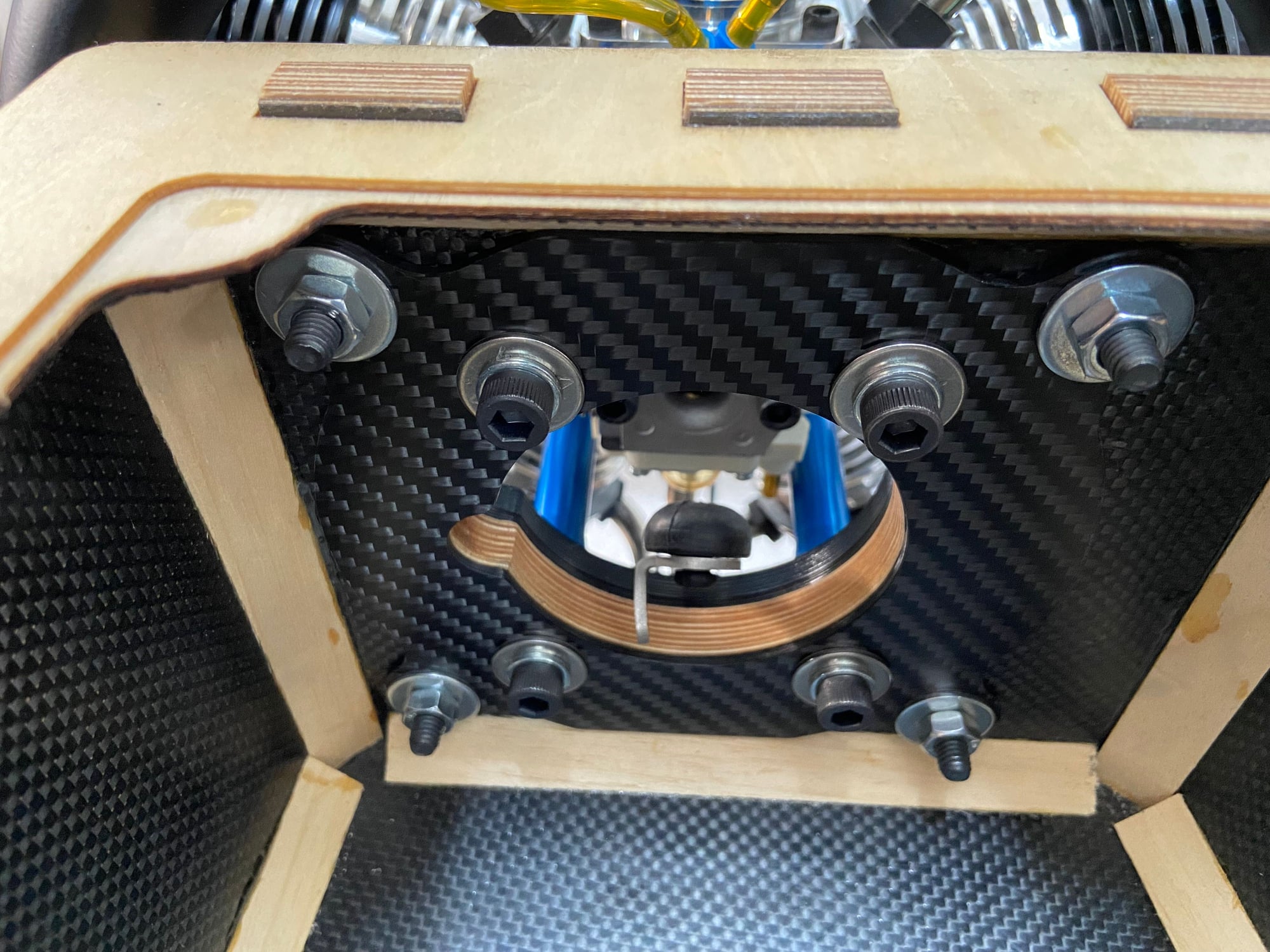

We have been busy with 12U travel baseball, so not a lot done on the UMS 150 in the Mamba 120. But I have milled all the parts and dry fitted the motor again and it looks like it's going to be a great fit and the Mamba 120 and UMS 150 is a good combo with no modifications to the firewall. I also used Seacraft Standoffs to spread the load on the mounting plate. Here are a couple pictures. I am currently working on the throttle and choke servo mounting, but we are on the road for the next three weeks for baseball tournaments so not sure how much is going to get done! Talk soon.

Last edited by JRSmith; 05-21-2024 at 02:44 PM.

The following users liked this post:

Hyjinx (05-22-2024)

#308

Yup! The "sticky" exhaust valves are a known glitch now. I have been adding SF straight on exposed stems before start up during pre run lubing and checks. Working it in and adding to mix of Amsoil and rec fuel. The other 125 at our field is experiencing the minor problem, he is using Jectron additive and lubing with wd 40 to no avail.

He just experienced a snapped cylinder base. Two ears broke off. (I am obtaining the damaged piston and jug for heat testing)

Can't wait to learn if these pistons are forged or cast. And what the clearance was on an incorrectly broke in engine

I have been testing temps on my 125. Open, baffled , non baffled, cowl on / off .

Very pleased with my motor. On my fifth gallon post 30:1.

He just experienced a snapped cylinder base. Two ears broke off. (I am obtaining the damaged piston and jug for heat testing)

Can't wait to learn if these pistons are forged or cast. And what the clearance was on an incorrectly broke in engine

I have been testing temps on my 125. Open, baffled , non baffled, cowl on / off .

Very pleased with my motor. On my fifth gallon post 30:1.

#309

Yup! The "sticky" exhaust valves are a known glitch now. I have been adding SF straight on exposed stems before start up during pre run lubing and checks. Working it in and adding to mix of Amsoil and rec fuel. The other 125 at our field is experiencing the minor problem, he is using Jectron additive and lubing with wd 40 to no avail.

He just experienced a snapped cylinder base. Two ears broke off. (I am obtaining the damaged piston and jug for heat testing)

Can't wait to learn if these pistons are forged or cast. And what the clearance was on an incorrectly broke in engine

I have been testing temps on my 125. Open, baffled , non baffled, cowl on / off .

Very pleased with my motor. On my fifth gallon post 30:1.

He just experienced a snapped cylinder base. Two ears broke off. (I am obtaining the damaged piston and jug for heat testing)

Can't wait to learn if these pistons are forged or cast. And what the clearance was on an incorrectly broke in engine

I have been testing temps on my 125. Open, baffled , non baffled, cowl on / off .

Very pleased with my motor. On my fifth gallon post 30:1.

#310

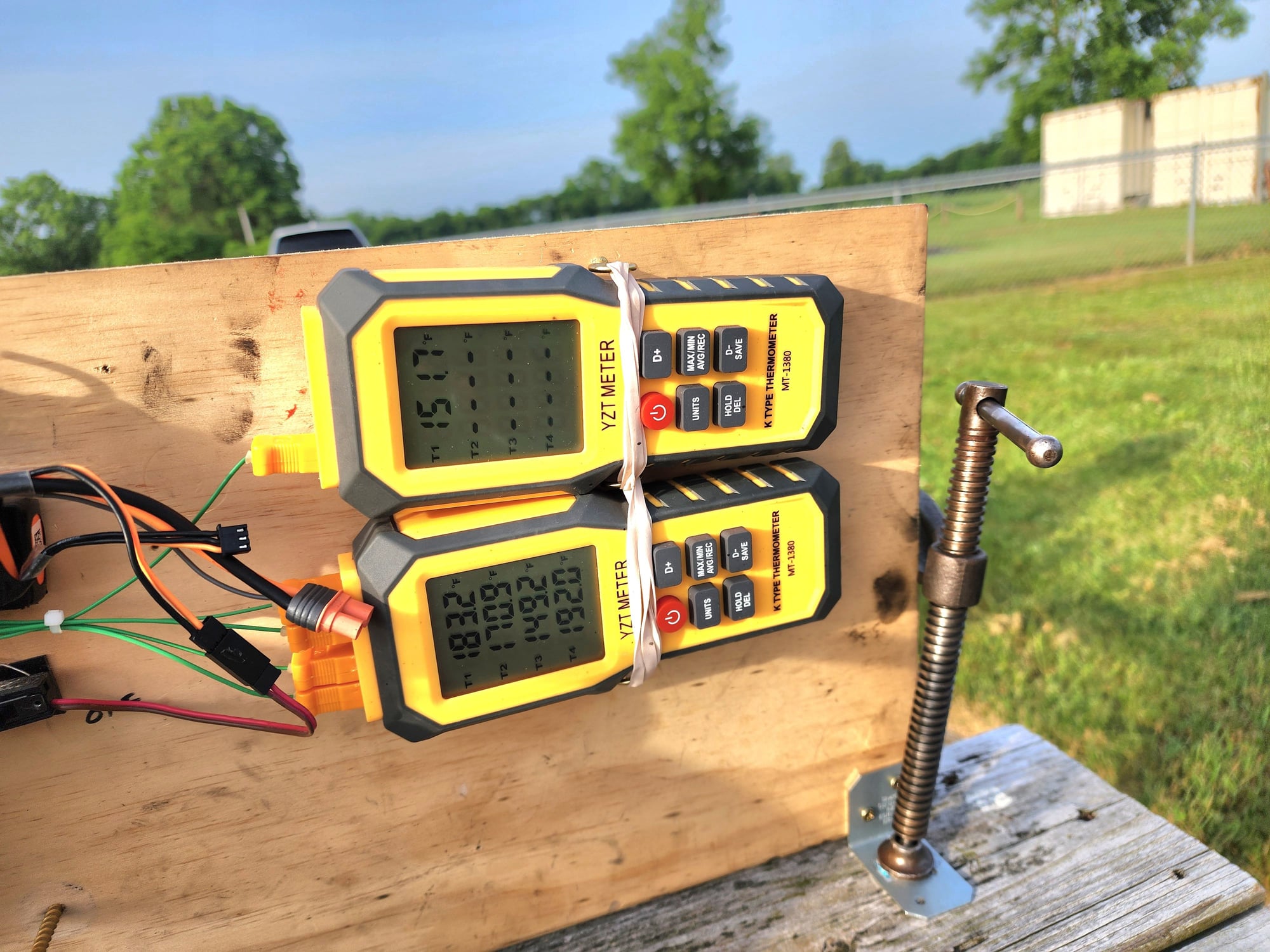

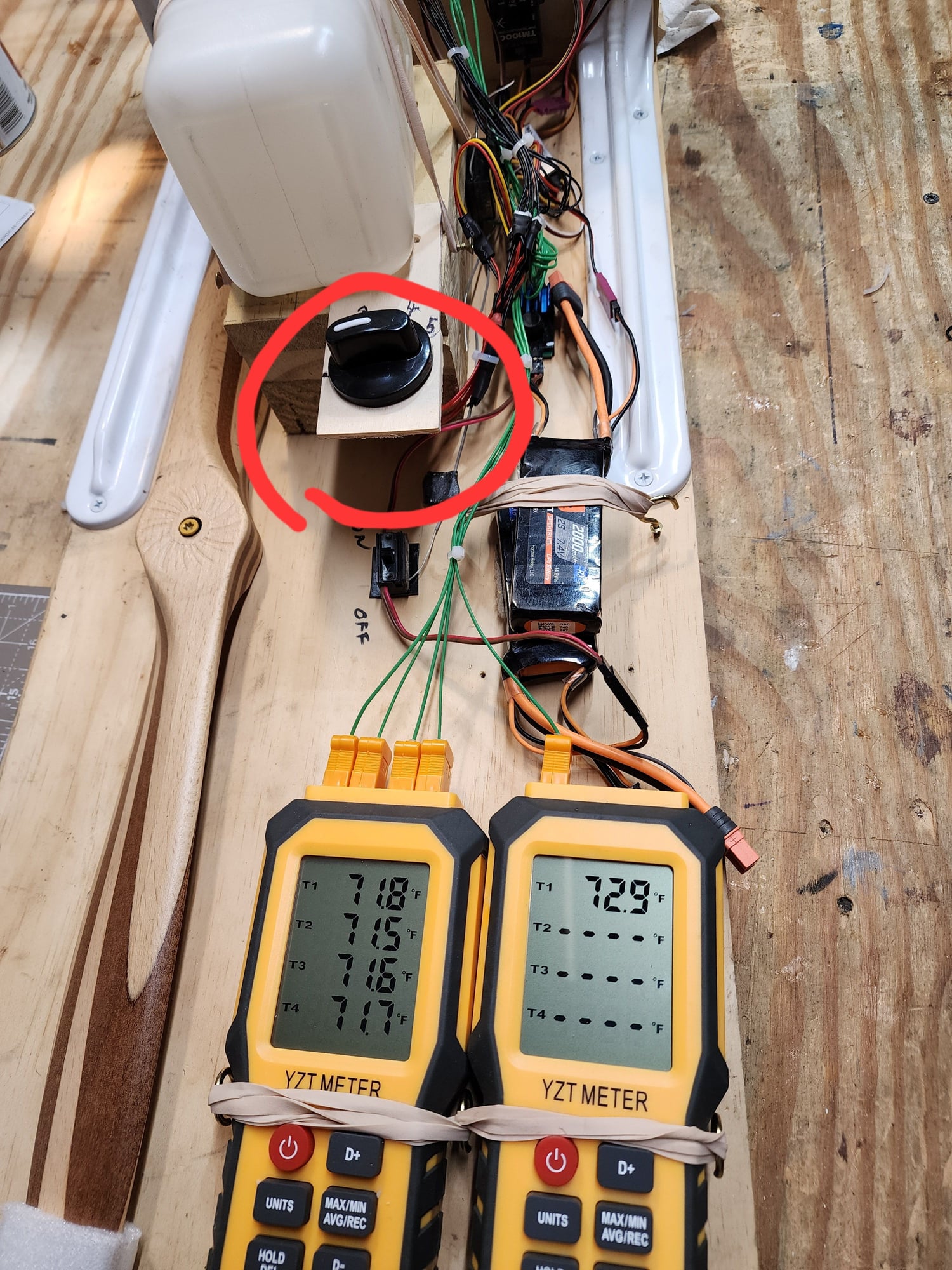

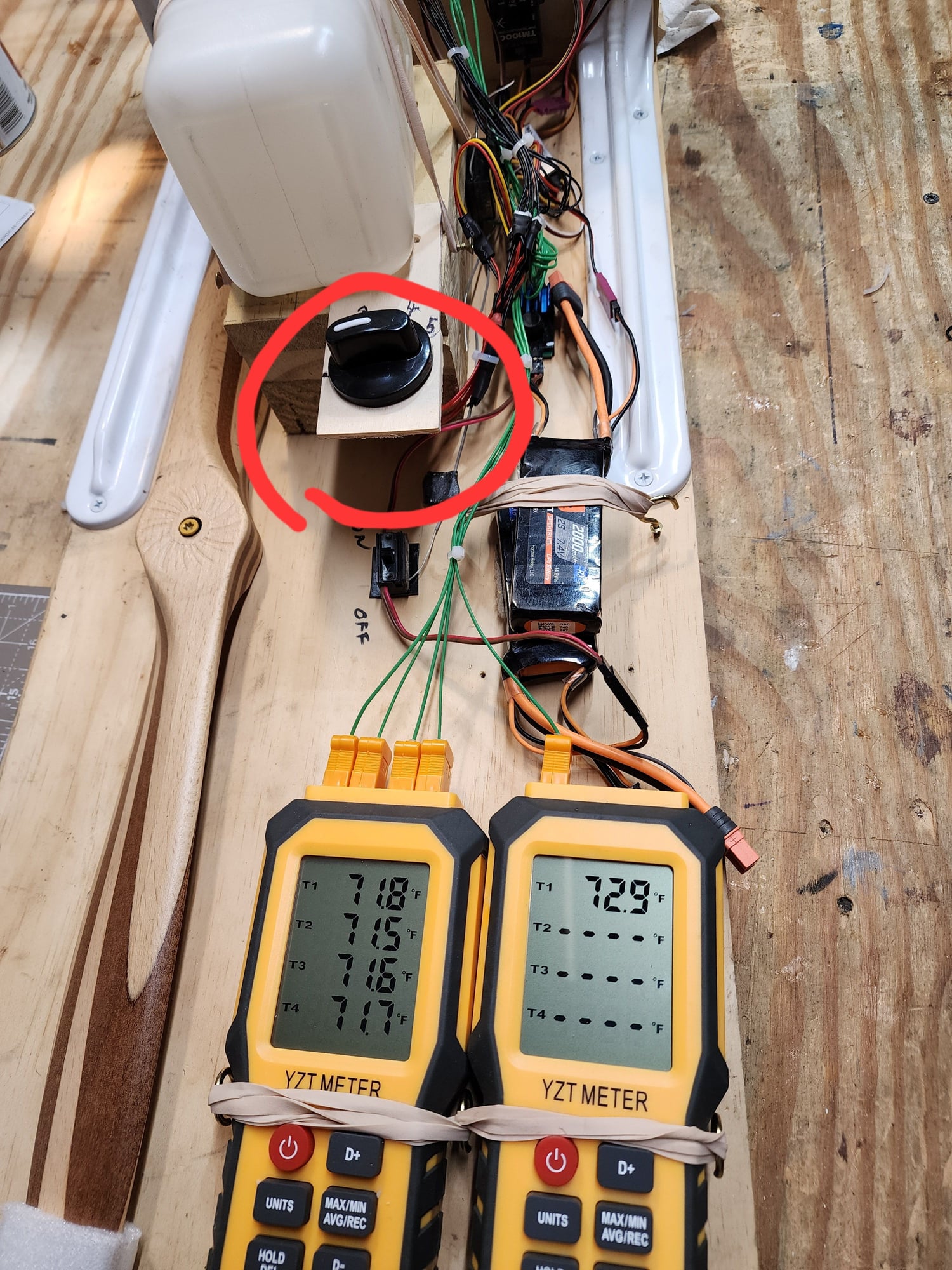

Here's my setup for checking temperatures on a bench run. K type sensor against spark plug held in place by the plug cap.

I also have a Spektrum temperature sensor on each cylinder agains5 the head fins.

An infrared thermal gun was almost usless.

I also have a Spektrum temperature sensor on each cylinder agains5 the head fins.

An infrared thermal gun was almost usless.

Last edited by Robert Dochterman; 05-23-2024 at 01:16 PM.

#311

Member

My Feedback: (1)

Yup! The "sticky" exhaust valves are a known glitch now. I have been adding SF straight on exposed stems before start up during pre run lubing and checks. Working it in and adding to mix of Amsoil and rec fuel. The other 125 at our field is experiencing the minor problem, he is using Jectron additive and lubing with wd 40 to no avail.

He just experienced a snapped cylinder base. Two ears broke off. (I am obtaining the damaged piston and jug for heat testing)

Can't wait to learn if these pistons are forged or cast. And what the clearance was on an incorrectly broke in engine

I have been testing temps on my 125. Open, baffled , non baffled, cowl on / off .

Very pleased with my motor. On my fifth gallon post 30:1.

He just experienced a snapped cylinder base. Two ears broke off. (I am obtaining the damaged piston and jug for heat testing)

Can't wait to learn if these pistons are forged or cast. And what the clearance was on an incorrectly broke in engine

I have been testing temps on my 125. Open, baffled , non baffled, cowl on / off .

Very pleased with my motor. On my fifth gallon post 30:1.

Chris

#312

I like your set up Robert. I am skeptical of low end big box infrared guns. Lots of guys at our field use them. Results all over the place.

I bought a fluke and it will be a better gage in hope. My first set of temps yielded between 180-220 after warm up and post 5 minute flights with no cowl no baffle and the Fluke close to the prop plate (approx) 6 inch. Resolution should be accurate measuring the cylinder between the bottom of the head and the top of the cyl base at that distance and repeatable. This is the area of greatest import to me personally. The heads probably more important to those researching the sticking valves. Remediation with SF has that a nothing burger to me. Until someone tears one of these down and checks clearances AND whether then guides are inserts or cast in the heads, the cylinder to piston fit and metallurgy with create the most heat and potential galling failures. I am most interested in longevity.

The engine with the failure at our field was incorrectly operated during its first uses. In my opinion, the "problems" with this engine were/are 100 % operator error, and not of value for consideration.

Currently out west sight seeing. So no data to add now.

Question to you. Which spectrum reciever will allow five inputs?

And did you break and resolder the wires to be able to get the sensor around the cylinders or remove the intake and exhaust tubes to install them?

Thank you for contributing to this thread Robert. Knowledge shared is wisdom gathered, and moves all forward.

Aaron- (Hyjinx) aka here.

I bought a fluke and it will be a better gage in hope. My first set of temps yielded between 180-220 after warm up and post 5 minute flights with no cowl no baffle and the Fluke close to the prop plate (approx) 6 inch. Resolution should be accurate measuring the cylinder between the bottom of the head and the top of the cyl base at that distance and repeatable. This is the area of greatest import to me personally. The heads probably more important to those researching the sticking valves. Remediation with SF has that a nothing burger to me. Until someone tears one of these down and checks clearances AND whether then guides are inserts or cast in the heads, the cylinder to piston fit and metallurgy with create the most heat and potential galling failures. I am most interested in longevity.

The engine with the failure at our field was incorrectly operated during its first uses. In my opinion, the "problems" with this engine were/are 100 % operator error, and not of value for consideration.

Currently out west sight seeing. So no data to add now.

Question to you. Which spectrum reciever will allow five inputs?

And did you break and resolder the wires to be able to get the sensor around the cylinders or remove the intake and exhaust tubes to install them?

Thank you for contributing to this thread Robert. Knowledge shared is wisdom gathered, and moves all forward.

Aaron- (Hyjinx) aka here.

#313

The green wire to the spark plug is for the yellow meters.I can read all 5 simultaneously.

The red wire is the Spektrum sensor, 1 of 5 cylinders which goes to a 5 position switch with one output to the telemetry port. I can read all five cylinders but only one at a time, on my tx. I install by lifting the tab on the connector and remove the wirewith pin

, wrap around the cylinder, then push the end back in to the connector.

i take engine heating seriously.😁

The red wire is the Spektrum sensor, 1 of 5 cylinders which goes to a 5 position switch with one output to the telemetry port. I can read all five cylinders but only one at a time, on my tx. I install by lifting the tab on the connector and remove the wirewith pin

, wrap around the cylinder, then push the end back in to the connector.

i take engine heating seriously.😁

The following users liked this post:

Hyjinx (05-24-2024)

#314

Another thing i notice while trying to get my engine to run cooler, turning the high speed needle out did not richen the mixture very much. Raising the fuel tank 12" gave me more head pressure which allowed me to richen it up enough to make the engine burbling rich. This engine will need a fuel pump.

#318

Hyjinx. Yes I like to share my observations to help the next guy out. Kinda of hard to find much info on these engines.

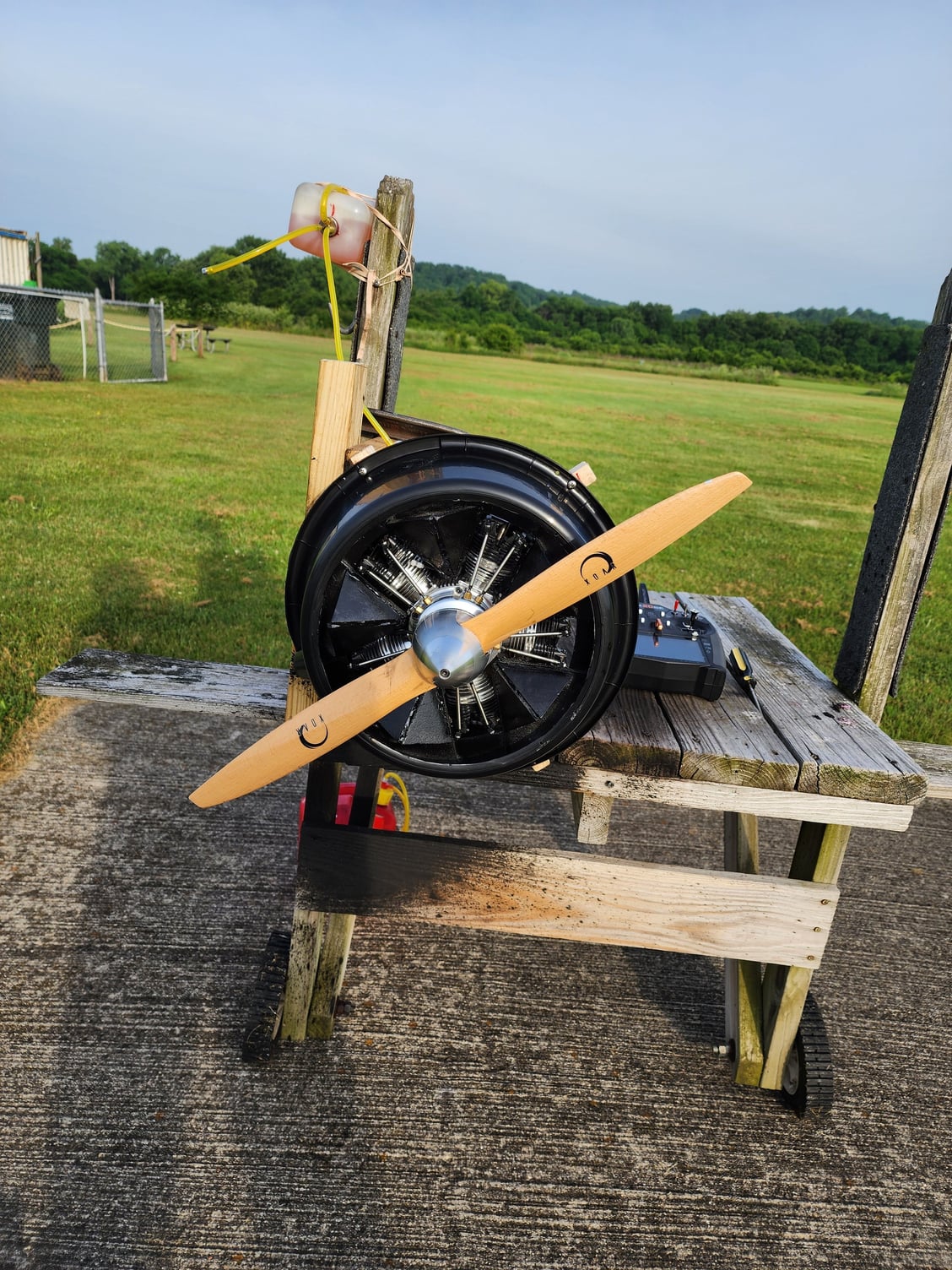

Here's another experiment of mine, using a leaf blower to simulate in flight airstream. This along with raising the fuel rank 12" for a rich mixture is the only way i can keep the temps under 225F degrees. Also a Xoar 24-10 prop put less load then the SEP 24-10 prop. About 300 rpm difference.

Here's another experiment of mine, using a leaf blower to simulate in flight airstream. This along with raising the fuel rank 12" for a rich mixture is the only way i can keep the temps under 225F degrees. Also a Xoar 24-10 prop put less load then the SEP 24-10 prop. About 300 rpm difference.

#320

Yes, 98 octane unleaded ethanol free at 32:1 Motorex oil from Sweden. Adrian said to try Amsoil Dominator.

Interesting about the prop. More pitch and diameter equals more load on the motor but at less rpm. Maybe the lower rpm is the solution? What brand prop?

Interesting about the prop. More pitch and diameter equals more load on the motor but at less rpm. Maybe the lower rpm is the solution? What brand prop?

The following users liked this post:

Robert Dochterman (05-24-2024)

#322

Today's experiment was for baffling. For a quick test I made it out of depron which doesn't deform until above 300F degrees. Instead of just blocking the airflow inbetween the cylinders, I added triangular pieces to deflect more and smoother airflow. This worked very well. Temperatures were stabilized for over 3 minutes with the top cylinder the hotest at 245F degrees.

Tomorrow I'll run it mounted 90 degrees rotated, on it's side. I want to see if the current top hotting running cylinder runs cooler in this orientation.

BTW, the cowling is a cut out oil drain pan from Walmart.

#325

[QUOTE=Robert Dochterman;12800851]Yes, 98 octane unleaded ethanol free at 32:1 Motorex oil from Sweden. Adrian said to try Amsoil Dominator.

Interesting about the prop. More pitch and diameter equals more load on the motor but at less rpm. Maybe the lower rpm is the solution? What brand prop?[/prope

Hi Robert. Interesting on the cooler temps on 90 degree orientation. Do you get the black thin exhaust residue with the Swedish oil mix? I run Amsoil Dominator (as recommended by Moki and UMS sellers here in the states.) It is certainly filthy, but if it reduces wear for longevity, I am ok cleaning it off after flights. Your take?

Interesting about the prop. More pitch and diameter equals more load on the motor but at less rpm. Maybe the lower rpm is the solution? What brand prop?[/prope

Hi Robert. Interesting on the cooler temps on 90 degree orientation. Do you get the black thin exhaust residue with the Swedish oil mix? I run Amsoil Dominator (as recommended by Moki and UMS sellers here in the states.) It is certainly filthy, but if it reduces wear for longevity, I am ok cleaning it off after flights. Your take?