UMS Gas Radial Engine Enthusiasts Rabbit Hole

#402

My Feedback: (62)

Report on my 5-100..................

I have installed the 5-100 in the 1/4 scale Phoenix Waco after the break in process. During the bench running the engine showed great promise. The Emcotech fuel pump was used at 5.5 volts. The ideal prop was a Xoar 25×12 at a bit over 4000 rpm. Idle was as low as 800 but over 1000 is most reliable. All cylinders are firing at all throttle settings. There is a slight lean zone at mid throttle. Richening the idle screw solves this. This is a true 5 hp engine and flies the big Waco with authority. Most flying is at less than 1/2 power. Full throttle on this plane is silly and grossly non scale. Huge loops are possible at 3/4 throttle. The engine is properly baffled. Using 1/32 Amsoil Dominator and 2oz/ gallon Seafoam. The engine is easy to start and so far after 15 flights, no dead stick. I would buy another 5-100.

Review left on CH-ignitions..........Tom

I have installed the 5-100 in the 1/4 scale Phoenix Waco after the break in process. During the bench running the engine showed great promise. The Emcotech fuel pump was used at 5.5 volts. The ideal prop was a Xoar 25×12 at a bit over 4000 rpm. Idle was as low as 800 but over 1000 is most reliable. All cylinders are firing at all throttle settings. There is a slight lean zone at mid throttle. Richening the idle screw solves this. This is a true 5 hp engine and flies the big Waco with authority. Most flying is at less than 1/2 power. Full throttle on this plane is silly and grossly non scale. Huge loops are possible at 3/4 throttle. The engine is properly baffled. Using 1/32 Amsoil Dominator and 2oz/ gallon Seafoam. The engine is easy to start and so far after 15 flights, no dead stick. I would buy another 5-100.

Review left on CH-ignitions..........Tom

#403

My Feedback: (2)

Thanks, Maxam.

I thought I would post my pump settings on my UMS 150 so others can chime in or benefit.

I mixed another channel to throttle for the pump. The mix range is -110% to 35% on my iX-20. At zero throttle stick, the pump is off. Any throttle increase turns the pump on. I am running the pump off a 2 S LiPo - my ignition battery.

The engine still needs to be choked. After about ten flips, the engine burped, turned off choke, moved throttle stick up a bit to engage pump, engine started after five flips. It ran quite smoothly throughout the throttle range. Idle rpm is about 1,000. Full throttle, 26X16, 3-bladed prop, 4500 rpm. Number 1 cylinder max temp 240.

Hi needle 1 3/4

Lo needle 1 5/8

I plan to fly her this week.

Comments welcome, I am still new to radials.

I thought I would post my pump settings on my UMS 150 so others can chime in or benefit.

I mixed another channel to throttle for the pump. The mix range is -110% to 35% on my iX-20. At zero throttle stick, the pump is off. Any throttle increase turns the pump on. I am running the pump off a 2 S LiPo - my ignition battery.

The engine still needs to be choked. After about ten flips, the engine burped, turned off choke, moved throttle stick up a bit to engage pump, engine started after five flips. It ran quite smoothly throughout the throttle range. Idle rpm is about 1,000. Full throttle, 26X16, 3-bladed prop, 4500 rpm. Number 1 cylinder max temp 240.

Hi needle 1 3/4

Lo needle 1 5/8

I plan to fly her this week.

Comments welcome, I am still new to radials.

Last edited by sharam; 08-19-2024 at 08:50 PM.

#404

My Feedback: (62)

Sharam, Definitely have the pump on at low idle!!!! Much easier to start AND avoid dead sticks when throttling down quickly. As the crankcase heats up internally the mixture is leaned out to a degree. That is why on a gas radial you want the idle mixture a bit on the rich side. On the bench at idle, when leaning out the idle screw you will see the engine speed up,,, lean a bit more and it slows down.........go back to the engine speeding up and richen to where it just begins to slow down, just. -Tom

#405

My Feedback: (2)

Tom, good advice, thanks. I reprogrammed the pump to come on at idle throttle trim and low throttle.

So, low throttle, least throttle trim, everything is off.

Low throttle, idle throttle trim, pump comes on.

Full pump action throughout throttle range now.

Modified my mix range to achieve these settings.

Also good thoughts on the idle mixture setting.

Thx again,

Second flight tomorrow.

So, low throttle, least throttle trim, everything is off.

Low throttle, idle throttle trim, pump comes on.

Full pump action throughout throttle range now.

Modified my mix range to achieve these settings.

Also good thoughts on the idle mixture setting.

Thx again,

Second flight tomorrow.

#406

Gents,

I have a UMS 180, 5 cylinder radial and about to set up telemetry parameters.

Does anyone know what max cylinder head temperature should be for alarm purposes?

Also for max RPM alarm I am assuming it would be 5500 RPM, would that be correct?

thanks

cheers

P

I have a UMS 180, 5 cylinder radial and about to set up telemetry parameters.

Does anyone know what max cylinder head temperature should be for alarm purposes?

Also for max RPM alarm I am assuming it would be 5500 RPM, would that be correct?

thanks

cheers

P

#407

I am just gussing here, but I think a head temperature of 135 deg C would be a good starting point, then carefully test what the engine will accept.

My way of determining is to start low and carefully examine the condition of the engine at each alarm, and raise the limit by a few degrees if everything (piston top appearance, sparkplug clour, exhaust valve appearance) turns out to be OK

What IMHO is more important: see if you can figure out a way in your TX to set up a deviation alarm, which is way more useful, because it will inform you on failing sparkplugs, or dropping cylinders due to issues with mixture distribution.

In my TX I have set up telemetry to return an average value, and a differentual alarm whenever a cylinder deviates 15 degrees above avg or 20 deg below.

RPM is a bit harder to tell (not familiar with UMS) but I'd say 5500 sounds about right for that size of engine. I take it, the manual states a max?

My way of determining is to start low and carefully examine the condition of the engine at each alarm, and raise the limit by a few degrees if everything (piston top appearance, sparkplug clour, exhaust valve appearance) turns out to be OK

What IMHO is more important: see if you can figure out a way in your TX to set up a deviation alarm, which is way more useful, because it will inform you on failing sparkplugs, or dropping cylinders due to issues with mixture distribution.

In my TX I have set up telemetry to return an average value, and a differentual alarm whenever a cylinder deviates 15 degrees above avg or 20 deg below.

RPM is a bit harder to tell (not familiar with UMS) but I'd say 5500 sounds about right for that size of engine. I take it, the manual states a max?

#408

thanks, manual states 1000 - 5500 RPM, I am thinking to lower the alarm down to say 5000 to keep it well under max. I was just advised of one of these UMS 180 5 cylinder engines failing in flight leading to loss of the model.

Temps I have no idea really will will start at 135C and run it, see what it does on the ground cowl off, then cowl on with baffles.

In the air I would expect it to run cooler perhaps.

cheers

P

Temps I have no idea really will will start at 135C and run it, see what it does on the ground cowl off, then cowl on with baffles.

In the air I would expect it to run cooler perhaps.

cheers

P

#410

I have sent him an email, will adjust pitch on the vario for max of 4500 RPM on the ground and set alarm perhaps 4800 RPM.

#412

My Feedback: (2)

I would check temps with telemetry if possible. See how hot you are running full throttle in the air and if temps are not excessive, there is probably room for higher RPM by leaning the hi needle a bit.

I like to run my engines a little richer and below their max rpm so hopefully they will last longer.

I like to run my engines a little richer and below their max rpm so hopefully they will last longer.

#413

I would check temps with telemetry if possible. See how hot you are running full throttle in the air and if temps are not excessive, there is probably room for higher RPM by leaning the hi needle a bit.

I like to run my engines a little richer and below their max rpm so hopefully they will last longer.

I like to run my engines a little richer and below their max rpm so hopefully they will last longer.

I am in the midst of a series of real world heat testing. #1 and 4 are the hottest with my motor running amsoil. 240 is the highest I've seen, with several baffle and non baffled tests.

I'm fine with that. Cowl off cowl on baffled and not. Not much difference.

For me the scale engines are run similar to the full scale. I'm not here for a screaming two stroke pulling a warbird around annoying the neighbors lol.

Aaron-

#414

I would check temps with telemetry if possible. See how hot you are running full throttle in the air and if temps are not excessive, there is probably room for higher RPM by leaning the hi needle a bit.

I like to run my engines a little richer and below their max rpm so hopefully they will last longer.

I like to run my engines a little richer and below their max rpm so hopefully they will last longer.

#415

I follow that same mentality Sharam. For the same reasons. My 125 rarely sees over half throttle with the exception of climb out.

I am in the midst of a series of real world heat testing. #1 and 4 are the hottest with my motor running amsoil. 240 is the highest I've seen, with several baffle and non baffled tests.

I'm fine with that. Cowl off cowl on baffled and not. Not much difference.

For me the scale engines are run similar to the full scale. I'm not here for a screaming two stroke pulling a warbird around annoying the neighbors lol.

Aaron-

I am in the midst of a series of real world heat testing. #1 and 4 are the hottest with my motor running amsoil. 240 is the highest I've seen, with several baffle and non baffled tests.

I'm fine with that. Cowl off cowl on baffled and not. Not much difference.

For me the scale engines are run similar to the full scale. I'm not here for a screaming two stroke pulling a warbird around annoying the neighbors lol.

Aaron-

#416

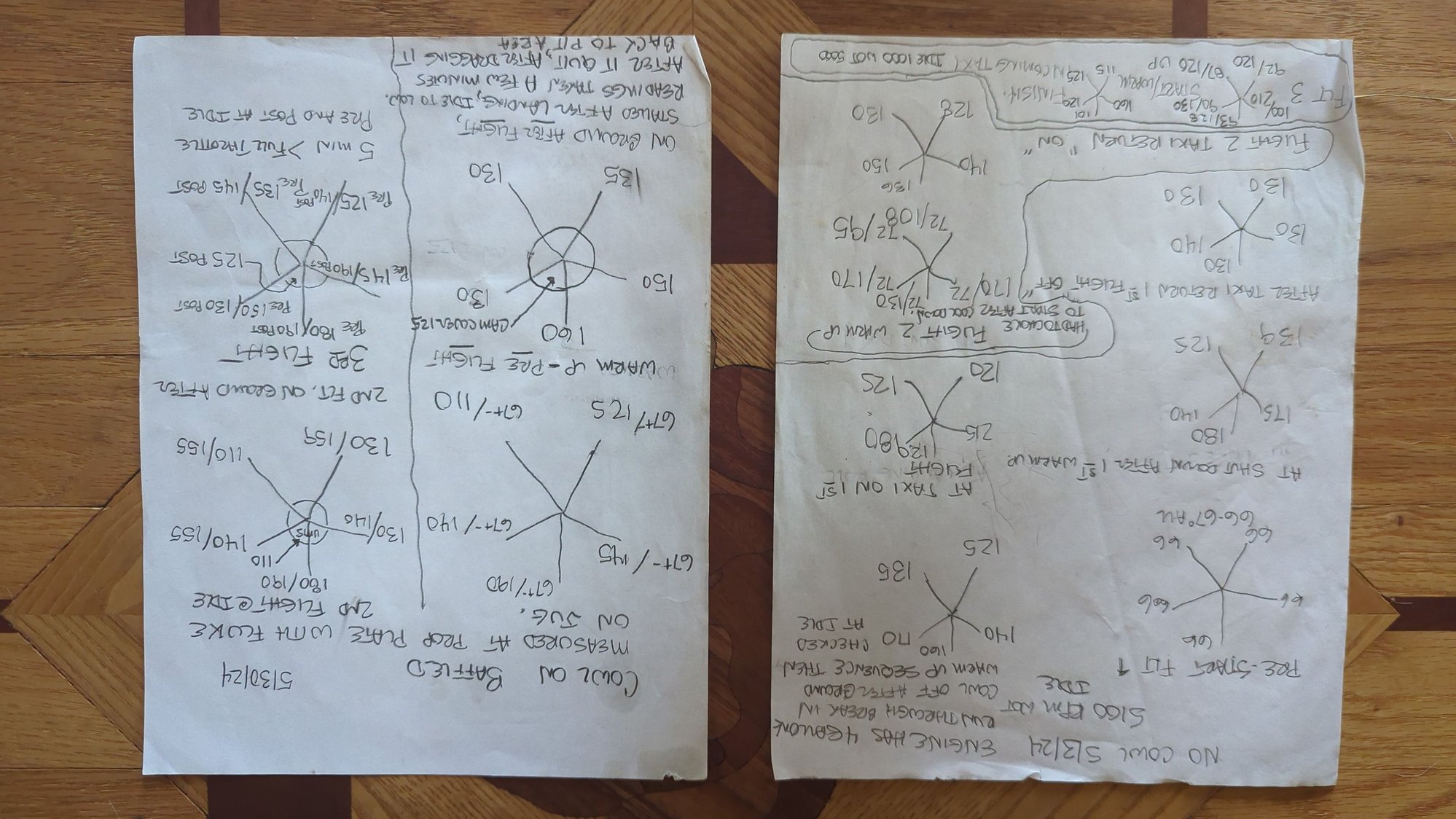

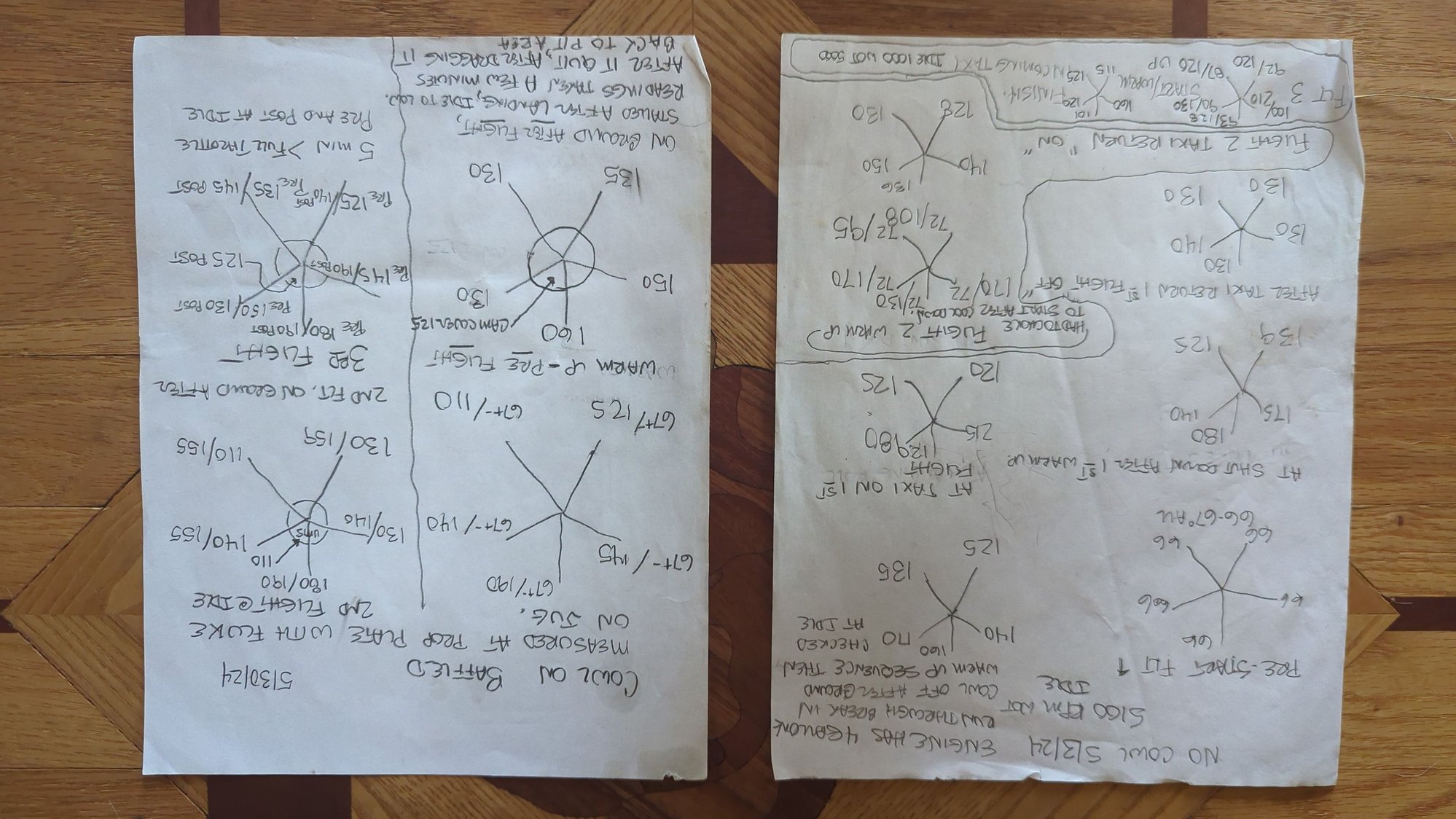

Goofed up on typing lol. 204 Fahrenheit is the highest I've seen with my 125 on these recent tests. Attached is the raw field data compiled this summer. Checks were cowl off un-baffled., and cowl on baffled. The #1 is typically highest. The spectrum radio this plane is on has poor telemetry options for multi cylinder applications. I haven't set up telemetry due to that. Going forward, monitoring #1 is probably ok as the highest representative temps. Please excuse crude data sheets, was just compiling for

myself.

I consider my engine in excellent condition. Properly broken in. Has 5 gallons thru it over two seasons.

FWIW

Aaron-

Aaron-

myself.

I consider my engine in excellent condition. Properly broken in. Has 5 gallons thru it over two seasons.

FWIW

Aaron-

Aaron-

#419

My Feedback: (2)

Tom, good advice, thanks. I reprogrammed the pump to come on at idle throttle trim and low throttle.

So, low throttle, least throttle trim, everything is off.

Low throttle, idle throttle trim, pump comes on.

Full pump action throughout throttle range now.

Modified my mix range to achieve these settings.

Also good thoughts on the idle mixture setting.

Thx again,

Second flight tomorrow.

So, low throttle, least throttle trim, everything is off.

Low throttle, idle throttle trim, pump comes on.

Full pump action throughout throttle range now.

Modified my mix range to achieve these settings.

Also good thoughts on the idle mixture setting.

Thx again,

Second flight tomorrow.

Max temp was 214 F on #1. I suspect temp was higher since my probe was a bit off from the base of the spark plug. Max rpm on the ground was 4480.

I have the following settings to run the pump:

a. lowest throttle trim, low throttle, pump is off.

b. idle throttle trim setting pump comes on - I flip start the engine in the usual way, choke first.

c. pump runs thereafter until I reduce throttle trim to lowest level or I engage throttle cut

d. mix range for pump channel is set at 2% at the lowest and 55% at the highest.

Engine ran reliably and sounded great. Hopefully the engine will now deliver years of service.

I really appreciate the info contained in this thread and thank all who take the time to post or reply.

#422

If somebody could do me a favor and just draw the outline on a piece of paper and send that to me or post it here. That'll also help.

Carlo, thank you, I sent you a private message the other day. Did you get it?

Carlo, thank you, I sent you a private message the other day. Did you get it?

Last edited by rexmexx; 09-16-2024 at 10:03 PM.