Saito FG-60R3

#2801

My Feedback: (7)

The radio quit and I crashed my Waco a while back. Amazingly enough it went in upside down in tall brush and aside from the wings it wasn't damaged. Here's the thing: it didn't even break the prop! I was able to get new wings and get it back in the air.

But even though the prop wasn't broken I've notice the engine seems to run differently now. It still starts as good as ever and runs well but the first flight of the day it almost always quits in flight. I adjust the mixture every time on the first flight of the day but apparently I never get it rich enough and it seems to die lean. After a dead stick landing I richen it up a little and it flies great the rest of the day.

The mixture also seems more "vague" now. The carb setup on these Saito radials has always been weird (with the high needle not doing much of anything and the low needle doing pretty much everything) but now the low needle adjustment can move more than half a turn without affecting much of a change. It was always a little vague but not this much.

I also has started doing something I had to get used to on my big gasser (DLE) airplanes: it does a "deep rpm dive" coming off of full throttle to idle. It did not do this before the crash. This is where it dies in flight - it dives too deep and quits. The idle is set plenty high but it dives on the way down.

Weird. Otherwise, after the first flight (and dead stick) of the day it runs fantastic!

But even though the prop wasn't broken I've notice the engine seems to run differently now. It still starts as good as ever and runs well but the first flight of the day it almost always quits in flight. I adjust the mixture every time on the first flight of the day but apparently I never get it rich enough and it seems to die lean. After a dead stick landing I richen it up a little and it flies great the rest of the day.

The mixture also seems more "vague" now. The carb setup on these Saito radials has always been weird (with the high needle not doing much of anything and the low needle doing pretty much everything) but now the low needle adjustment can move more than half a turn without affecting much of a change. It was always a little vague but not this much.

I also has started doing something I had to get used to on my big gasser (DLE) airplanes: it does a "deep rpm dive" coming off of full throttle to idle. It did not do this before the crash. This is where it dies in flight - it dives too deep and quits. The idle is set plenty high but it dives on the way down.

Weird. Otherwise, after the first flight (and dead stick) of the day it runs fantastic!

Last edited by mitchilito; 10-13-2023 at 02:56 AM.

#2804

Member

The FG60R3 carburetor does not have an internal filter (unlike the Walbros). And if small debris or dust enters with the gasoline, it is almost impossible to clean it properly. These impurities then block the internal conduits and prevent correct adjustment of the carburetor.

Only one solution: a lot of patience to clean the carburetor.

JM

Only one solution: a lot of patience to clean the carburetor.

JM

#2805

My Feedback: (7)

The FG60R3 carburetor does not have an internal filter (unlike the Walbros). And if small debris or dust enters with the gasoline, it is almost impossible to clean it properly. These impurities then block the internal conduits and prevent correct adjustment of the carburetor.

Only one solution: a lot of patience to clean the carburetor.

JM

Only one solution: a lot of patience to clean the carburetor.

JM

It's running well enough at the moment but some day (

) I'll clean this crazy carb and install a filter also.

) I'll clean this crazy carb and install a filter also.

#2806

My Feedback: (3)

I was running a felt clunk on my FG-21 and fibers from the clunk got into the carb and it was causing all sorts of problems like unable to get a consistant tune, lean runs, etc. The FG-60R3 is the same type of carb. Maybe order a rebuild kit from Horizon and open it up and clean it out.

#2807

I was running a felt clunk on my FG-21 and fibers from the clunk got into the carb and it was causing all sorts of problems like unable to get a consistant tune, lean runs, etc. The FG-60R3 is the same type of carb. Maybe order a rebuild kit from Horizon and open it up and clean it out.

I have never had any issues with what you mention despite now at least 10 different of these set-ups with the feltclunks I use.

I have experienced problems with feltclunks as sold by HobbyKing and comparable outlets, I use exclusively these: https://i0.wp.com/www.justengines.co...24%2C324&ssl=1 and yet have to have the first issue with them.

#2808

Member

Hi guys.

A video made a few days ago with an FG60R3 from 2014, therefore an engine from the 1st production series. This engine has over 60 hours of operation. Modifications made to this engine:

- compression rate reduced by increasing the thickness of the cylinder base gasket

- passage of gases through the bottom of the engine (crankshaft)

- modification of the ignition sequence (MMM ring)

Enjoy the purr of this engine running at 5000 rpm on this Stinson Reliant from Phoenix Model

JM

A video made a few days ago with an FG60R3 from 2014, therefore an engine from the 1st production series. This engine has over 60 hours of operation. Modifications made to this engine:

- compression rate reduced by increasing the thickness of the cylinder base gasket

- passage of gases through the bottom of the engine (crankshaft)

- modification of the ignition sequence (MMM ring)

Enjoy the purr of this engine running at 5000 rpm on this Stinson Reliant from Phoenix Model

JM

The following users liked this post:

Hyjinx (05-07-2024)

#2809

My Feedback: (7)

Well, folks, I've been operating this engine for several seasons and I'm finally throwing in the towel! Yes, it can be made to run adequately, for the most part. But you know from the start that setting the carb mixture on this engine is a compromise when you only have ONE mixture needle to work with! Lately, for some reason that I cannot identify or fix, it has been almost impossible to keep running at low idle. (And, no, I don't need troubleshooting help here :-)

The gist of all this is that I"m finally going to do what I always wanted to do and that is install a Walbro carburetor on it so I have complete control of the mixture range - which you most assuredly do NOT have with the stock carb. The down side is that I will have to run an electric fuel pump to supply fuel to the carb. However, C&H (and Morris Mini Motors) both sell a nice, small, and relatively inexpensive fuel pump that runs directly off of the receiver.

Morris also sells a conversion package of these components but I am going to machine my own Walbro mount adaptor and insulator block (to prevent vapor lock - which I think is part of my problem now). I'm installing a Walbro off of the Stinger 15cc 2-cycle engine (google it if interested) of which I've used several in my past conversion projects and they run GREAT. I'll post pictures here as I go along.

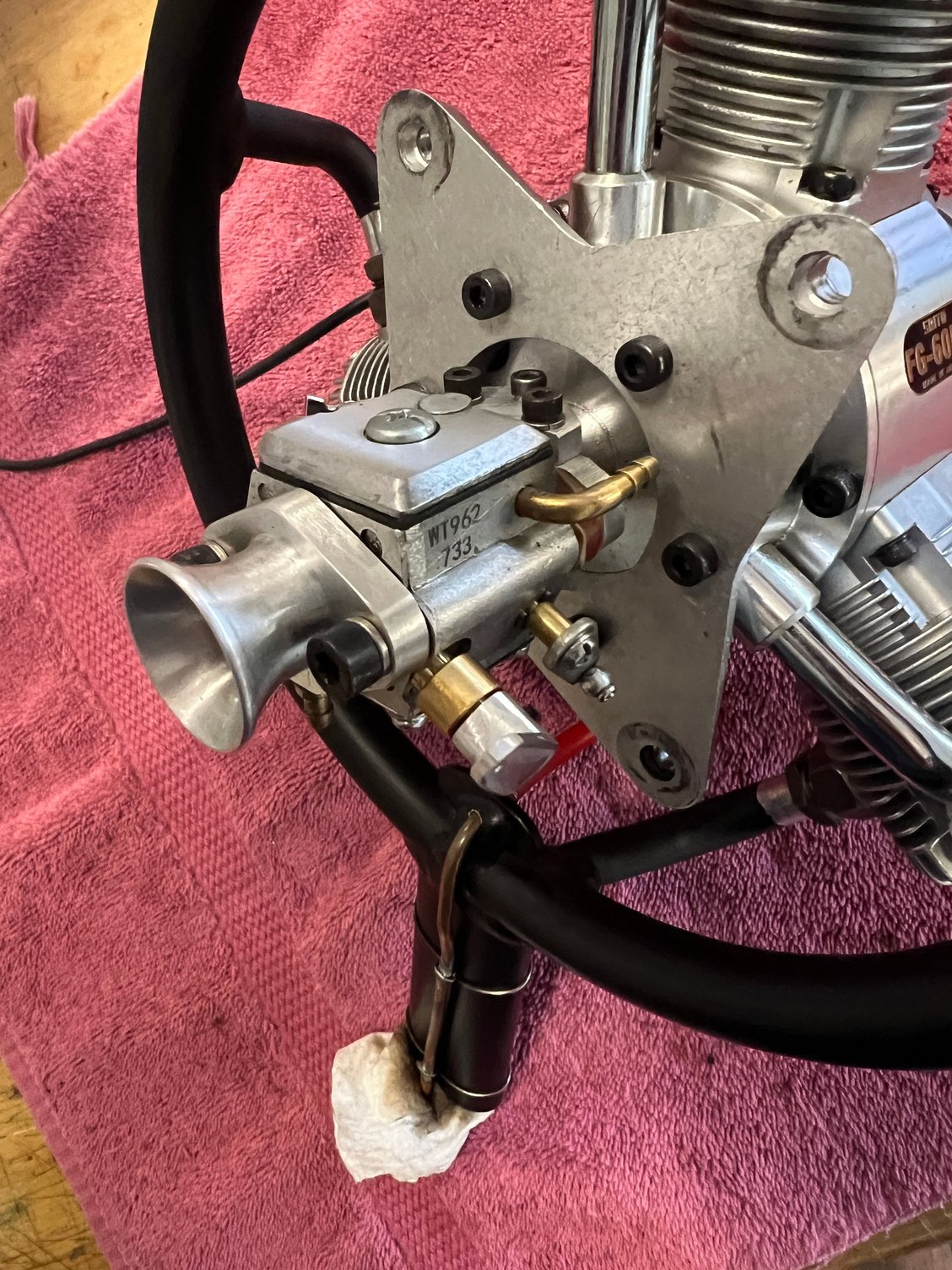

Here's the heart of the problem. Can't wait to see it go!

The gist of all this is that I"m finally going to do what I always wanted to do and that is install a Walbro carburetor on it so I have complete control of the mixture range - which you most assuredly do NOT have with the stock carb. The down side is that I will have to run an electric fuel pump to supply fuel to the carb. However, C&H (and Morris Mini Motors) both sell a nice, small, and relatively inexpensive fuel pump that runs directly off of the receiver.

Morris also sells a conversion package of these components but I am going to machine my own Walbro mount adaptor and insulator block (to prevent vapor lock - which I think is part of my problem now). I'm installing a Walbro off of the Stinger 15cc 2-cycle engine (google it if interested) of which I've used several in my past conversion projects and they run GREAT. I'll post pictures here as I go along.

Here's the heart of the problem. Can't wait to see it go!

Last edited by mitchilito; 05-28-2024 at 04:53 AM.

#2811

Well, folks, I've been operating this engine for several seasons and I'm finally throwing in the towel! Yes, it can be made to run adequately, for the most part. But you know from the start that setting the carb mixture on this engine is a compromise when you only have ONE mixture needle to work with! Lately, for some reason that I cannot identify or fix, it has been almost impossible to keep running at low idle. (And, no, I don't need troubleshooting help here :-)

The gist of all this is that I"m finally going to do what I always wanted to do and that is install a Walbro carburetor on it so I have complete control of the mixture range - which you most assuredly do NOT have with the stock carb. The down side is that I will have to run an electric fuel pump to supply fuel to the carb. However, C&H (and Morris Mini Motors) both sell a nice, small, and relatively inexpensive fuel pump that runs directly off of the receiver.

Morris also sells a conversion package of these components but I am going to machine my own Walbro mount adaptor and insulator block (to prevent vapor lock - which I think is part of my problem now). I'm installing a Walbro off of the Stinger 15cc 2-cycle engine (google it if interested) of which I've used several in my past conversion projects and they run GREAT. I'll post pictures here as I go along.

Here's the heart of the problem. Can't wait to see it go!

The gist of all this is that I"m finally going to do what I always wanted to do and that is install a Walbro carburetor on it so I have complete control of the mixture range - which you most assuredly do NOT have with the stock carb. The down side is that I will have to run an electric fuel pump to supply fuel to the carb. However, C&H (and Morris Mini Motors) both sell a nice, small, and relatively inexpensive fuel pump that runs directly off of the receiver.

Morris also sells a conversion package of these components but I am going to machine my own Walbro mount adaptor and insulator block (to prevent vapor lock - which I think is part of my problem now). I'm installing a Walbro off of the Stinger 15cc 2-cycle engine (google it if interested) of which I've used several in my past conversion projects and they run GREAT. I'll post pictures here as I go along.

Here's the heart of the problem. Can't wait to see it go!

Aaron

#2812

My Feedback: (7)

Hi Mitch. Please post your results. Been some complaining recently here about the walbros being flat in transition between the high and low circuits without an intermediate circuit on the larger radials. Interested to see if that shows up with this application. i don't seem to be experiencing it with my UMS 125. But i think the walbro on it is larger. Being a radial, i don't really "hot rod" the radials so fast transitions aren't really my bag, but i would still like to get your take on this. Hope your spring/summer is going well.

Aaron

Aaron

Gemini 300 conversion if you haven't already seen it:

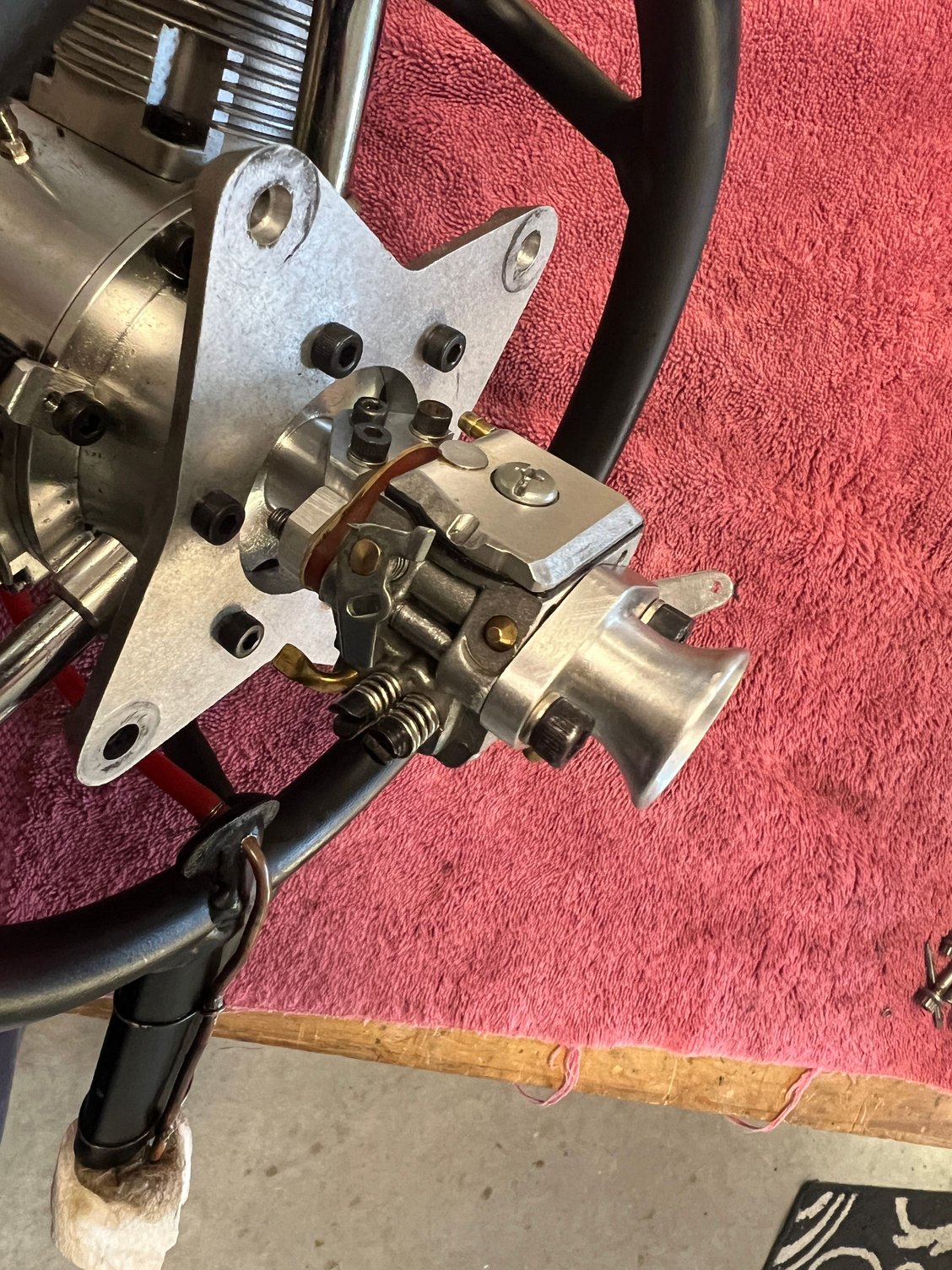

The pump on top of the carb now has no function whatsoever in this installation. And I'll have to redirect the in fuel inlet which is easy - it's just a taper fit into the carb.

Last edited by mitchilito; 05-30-2024 at 02:16 AM.

#2813

The smaller carb definitely makes sense. Can you get away with no external pump on a lower vacuum radial crankcase and smaller venturi? I wonder if the triple may have greater vaccum with the less volumetric crankcase.

#2814

My Feedback: (7)

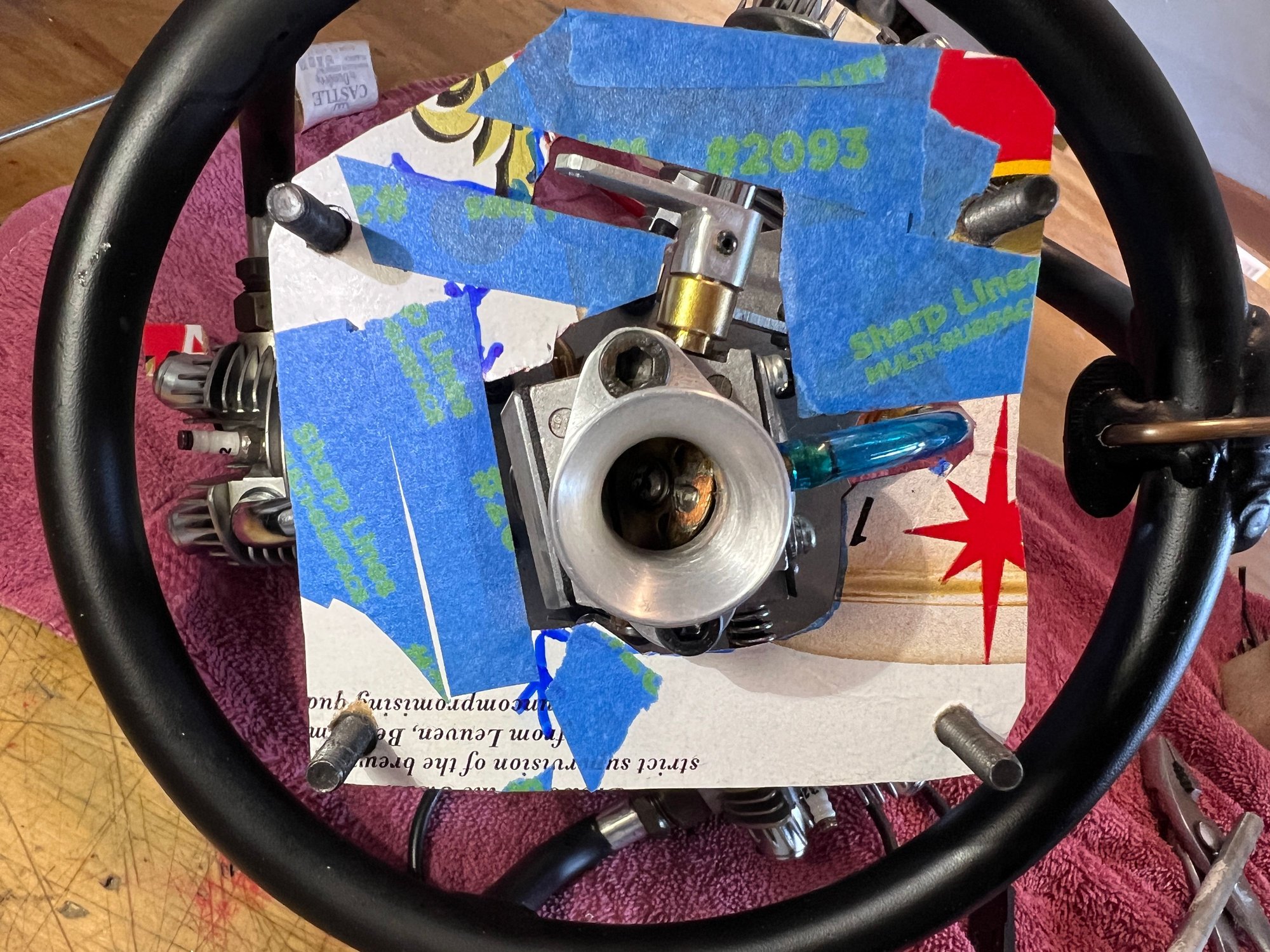

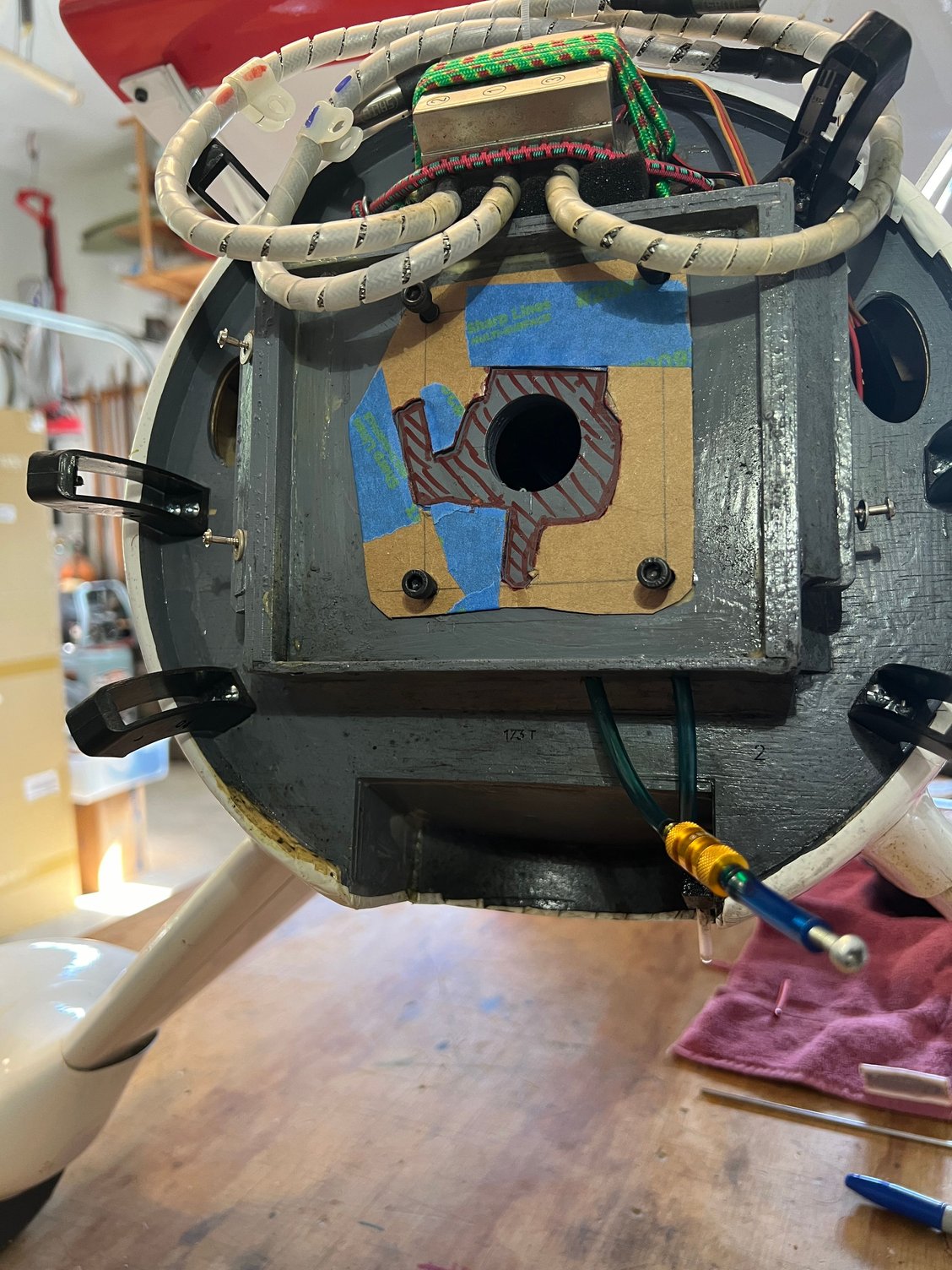

One downside of the RG60R3 conversion it the carb protrudes farther back toward the firewall. I had to do some serious firewall trimming!

Made a template. Here's a good pic of my crankcase rebreather too.

Blue tape refines the edges

Transferred to firewall

Last edited by mitchilito; 05-31-2024 at 02:10 AM.

#2816

My Feedback: (7)

Well here's the final report: this carb conversion is ASTOUNDING. It started second flip off the bench and runs like a watch. Honestly, I have never had a walbro equipped engine run this well. This has to be a result of the super steady fuel supply the pump provides. Honestly, it almost seems like an electric motor - but sounds like a gnarly radial! I LOVE it. Plus, I can now choke it from the front of the airplane (I put the choke knob to come through the engine baffles) so you don't have to take off the canopy hatch to hand choke it.

The pump setup is a very simple and neat install that connects directly to a receiver channel and I put I on a switch so I can turn it off at will - which I do right after shutdown. The pump also has a speed (volume) adjustment on the back and while running the engine at full power I turned it down as much as possible until effected the mixture. Well, turns out it uses ALL the flow available from this pump. I will say this: I have a fairly restrictive T-fitting in the line which MIGHT be effecting this. But it's no big deal cuz, like I said, it runs amazing.

This carb came directly off my Gemini 300 gas conversion with no changes. I think the gemini runs great but if you let her idle for any length of time and then jam on the throttle she will load up with fuel and then sputter a little to get cleared out. No big deal, but this electric pump set up displays NONE of that behavior. Even after extended idling it will instantly go to full power without missing a beat. FANTASTIC!!

BIG hole in the firewall! Brass tubes on the right guide the mixture adjust screwdriver.

Pump to the left of the tank. Simple and effective.

Choke lever (on right of carb) rod exits through engine baffles. So convenient!

The pump setup is a very simple and neat install that connects directly to a receiver channel and I put I on a switch so I can turn it off at will - which I do right after shutdown. The pump also has a speed (volume) adjustment on the back and while running the engine at full power I turned it down as much as possible until effected the mixture. Well, turns out it uses ALL the flow available from this pump. I will say this: I have a fairly restrictive T-fitting in the line which MIGHT be effecting this. But it's no big deal cuz, like I said, it runs amazing.

This carb came directly off my Gemini 300 gas conversion with no changes. I think the gemini runs great but if you let her idle for any length of time and then jam on the throttle she will load up with fuel and then sputter a little to get cleared out. No big deal, but this electric pump set up displays NONE of that behavior. Even after extended idling it will instantly go to full power without missing a beat. FANTASTIC!!

BIG hole in the firewall! Brass tubes on the right guide the mixture adjust screwdriver.

Pump to the left of the tank. Simple and effective.

Choke lever (on right of carb) rod exits through engine baffles. So convenient!

Last edited by mitchilito; 06-04-2024 at 02:36 AM.

The following users liked this post:

JieM (06-05-2024)

#2817

My Feedback: (7)

Let's call this the month and a half update - and there were some interesting developments!

As I said, this engine/carb conversion was running GREAT. And then the engine quit on me when the plane was low and upside down last week and caused a forced landing. The good news is, the plane wasn't damage too bad and is back good as new. The engine had given me some warnings by sputtering sometimes through the rolls but I just figured I needed to adjust the carb. But after I got the minor airframe damage fixed the engine clearly wasn't running right.

It would start and transition well but it would NOT peak out to full power. Long story short I checked every single thing that could be a cause including swapping walbro carbs but nothing made the slightest difference. I was FRUSTRATED. Then I thought of what Sherlock Holmes said, "when you've eliminated all the possible causes, look at the impossible ones!"

I run ASPEN (alkylate) fuel in all my model engines. It's not cheap but it doesn't' have all the horrible additives and water that regular pump gas has. The down side is it's expensive. But money's no object when it comes to our babies, right? Generally speaking I considered it impossible that the fuel could be bad but I mixed up a pint of regular pump gas and long story short - the engine was back to running like a TOP!! I thought back about that last batch of ASPEN and realized I just mixed it up. I have two cases (of quarts) so I dumped that fuel and mixed up another two quarts from the same box. I took it out yesterday and flew the living crap out of it and it is running so good I could cry!

After about a million flights of gasoline engines this is only the second time I've heard of the gasoline causing the problem.

OUCH

Good as new

As I said, this engine/carb conversion was running GREAT. And then the engine quit on me when the plane was low and upside down last week and caused a forced landing. The good news is, the plane wasn't damage too bad and is back good as new. The engine had given me some warnings by sputtering sometimes through the rolls but I just figured I needed to adjust the carb. But after I got the minor airframe damage fixed the engine clearly wasn't running right.

It would start and transition well but it would NOT peak out to full power. Long story short I checked every single thing that could be a cause including swapping walbro carbs but nothing made the slightest difference. I was FRUSTRATED. Then I thought of what Sherlock Holmes said, "when you've eliminated all the possible causes, look at the impossible ones!"

I run ASPEN (alkylate) fuel in all my model engines. It's not cheap but it doesn't' have all the horrible additives and water that regular pump gas has. The down side is it's expensive. But money's no object when it comes to our babies, right? Generally speaking I considered it impossible that the fuel could be bad but I mixed up a pint of regular pump gas and long story short - the engine was back to running like a TOP!! I thought back about that last batch of ASPEN and realized I just mixed it up. I have two cases (of quarts) so I dumped that fuel and mixed up another two quarts from the same box. I took it out yesterday and flew the living crap out of it and it is running so good I could cry!

After about a million flights of gasoline engines this is only the second time I've heard of the gasoline causing the problem.

OUCH

Good as new

#2818

Hey Mitch. That's quite the deduction. Well played Sir. Nice to see dual Waco's in one place. I the old days, we blamed the gas first, then replaced the points, condenser and cap with wires and plugs. Lol.

Hey, which walbro part number are u using on this R-3. I am doing some Sherlocking on a problem with a Saito R -5 converted to gas. Trying to balance the needle spring to prevent the pump from overpressureing the valve and flooding the three idle and transition holes. Making normal tuning impossible.

Aaron-

.

Hey, which walbro part number are u using on this R-3. I am doing some Sherlocking on a problem with a Saito R -5 converted to gas. Trying to balance the needle spring to prevent the pump from overpressureing the valve and flooding the three idle and transition holes. Making normal tuning impossible.

Aaron-

.

#2819

My Feedback: (7)

Hey Mitch. That's quite the deduction. Well played Sir. Nice to see dual Waco's in one place. I the old days, we blamed the gas first, then replaced the points, condenser and cap with wires and plugs. Lol.

Hey, which walbro part number are u using on this R-3. I am doing some Sherlocking on a problem with a Saito R -5 converted to gas. Trying to balance the needle spring to prevent the pump from overpressureing the valve and flooding the three idle and transition holes. Making normal tuning impossible.

Aaron-

.

Hey, which walbro part number are u using on this R-3. I am doing some Sherlocking on a problem with a Saito R -5 converted to gas. Trying to balance the needle spring to prevent the pump from overpressureing the valve and flooding the three idle and transition holes. Making normal tuning impossible.

Aaron-

.

What kind of pump are you using? I'm using the little jewel that C&H sells which is working great. As I may have mentioned I have it on a switch whch I turn off whenever the engine isn't running.

#2820

Hey Mitch

Adrian sent WA' s with two gas conversions. One on my Saito R5 and one on my Seidel 7-77. The 77 is proving out well with a TDS Micropumps. It was problematic tuning with the APS. The Saito is not happy with the emotech (APS). I bought the TDS and am impressed with it's simplicity and ultra low delivery capability.

Trying to stay with the APS for the Saito as the airframe is set up with it . Problem is balancing the inlet needle and seat spring to the engines need (which is minor). The WA spring is just letting the pump overrun the circuity and flood in the low end.

I obtained several spring lengths and strengths from a local shop that had the OEM Walbro springs. The WT series has a stronger spring than the WA. I've been working with Walbro tech's on the issue. They have been helpful. And a little surprised this usage is working at all with these external pumps lol.

Now retired, I'm busier than ever. Progress is a slow as pissing these days.

Hope your summer has been well. Had a boo boo with my Waco. Yours is on the assembly bench!

Adrian sent WA' s with two gas conversions. One on my Saito R5 and one on my Seidel 7-77. The 77 is proving out well with a TDS Micropumps. It was problematic tuning with the APS. The Saito is not happy with the emotech (APS). I bought the TDS and am impressed with it's simplicity and ultra low delivery capability.

Trying to stay with the APS for the Saito as the airframe is set up with it . Problem is balancing the inlet needle and seat spring to the engines need (which is minor). The WA spring is just letting the pump overrun the circuity and flood in the low end.

I obtained several spring lengths and strengths from a local shop that had the OEM Walbro springs. The WT series has a stronger spring than the WA. I've been working with Walbro tech's on the issue. They have been helpful. And a little surprised this usage is working at all with these external pumps lol.

Now retired, I'm busier than ever. Progress is a slow as pissing these days.

Hope your summer has been well. Had a boo boo with my Waco. Yours is on the assembly bench!

#2821

My Feedback: (7)

Hey Mitch

Adrian sent WA' s with two gas conversions. One on my Saito R5 and one on my Seidel 7-77. The 77 is proving out well with a TDS Micropumps. It was problematic tuning with the APS. The Saito is not happy with the emotech (APS). I bought the TDS and am impressed with it's simplicity and ultra low delivery capability.

Trying to stay with the APS for the Saito as the airframe is set up with it . Problem is balancing the inlet needle and seat spring to the engines need (which is minor). The WA spring is just letting the pump overrun the circuity and flood in the low end.

I obtained several spring lengths and strengths from a local shop that had the OEM Walbro springs. The WT series has a stronger spring than the WA. I've been working with Walbro tech's on the issue. They have been helpful. And a little surprised this usage is working at all with these external pumps lol.

Now retired, I'm busier than ever. Progress is a slow as pissing these days.

Hope your summer has been well. Had a boo boo with my Waco. Yours is on the assembly bench!

Adrian sent WA' s with two gas conversions. One on my Saito R5 and one on my Seidel 7-77. The 77 is proving out well with a TDS Micropumps. It was problematic tuning with the APS. The Saito is not happy with the emotech (APS). I bought the TDS and am impressed with it's simplicity and ultra low delivery capability.

Trying to stay with the APS for the Saito as the airframe is set up with it . Problem is balancing the inlet needle and seat spring to the engines need (which is minor). The WA spring is just letting the pump overrun the circuity and flood in the low end.

I obtained several spring lengths and strengths from a local shop that had the OEM Walbro springs. The WT series has a stronger spring than the WA. I've been working with Walbro tech's on the issue. They have been helpful. And a little surprised this usage is working at all with these external pumps lol.

Now retired, I'm busier than ever. Progress is a slow as pissing these days.

Hope your summer has been well. Had a boo boo with my Waco. Yours is on the assembly bench!

I had the Waco out again yesterday and as I said it is running just fantastically. I tried turning down the pump volume to see where it would affect the saito mixture and this time I got it at full low delivery volume and it still delivered plenty of fuel. I'm not sure why I had different results the first time I tried this. But I flew it all day and can't say enough good things about the power/transitions etc. What a fantastic airframe/engine combination this is.

Last edited by mitchilito; 08-26-2024 at 03:05 AM.

#2825

My Feedback: (7)

Okay, this is some fantastic information. I, too, have APS pumps, one of them on my Moki 300, and haven't had the spring "overpressure" yet. I can't remember the series number of the pump on my Moki 300 . . . . .

I had the Waco out again yesterday and as I said it is running just fantastically. I tried turning down the pump volume to see where it would affect the saito mixture and this time I got it at full low delivery volume and it still delivered plenty of fuel. I'm not sure why I had different results the first time I tried this. But I flew it all day and can't say enough good things about the power/transitions etc. What a fantastic airframe/engine combination this is.

I had the Waco out again yesterday and as I said it is running just fantastically. I tried turning down the pump volume to see where it would affect the saito mixture and this time I got it at full low delivery volume and it still delivered plenty of fuel. I'm not sure why I had different results the first time I tried this. But I flew it all day and can't say enough good things about the power/transitions etc. What a fantastic airframe/engine combination this is.

Just thought I'd add that to this conversation.