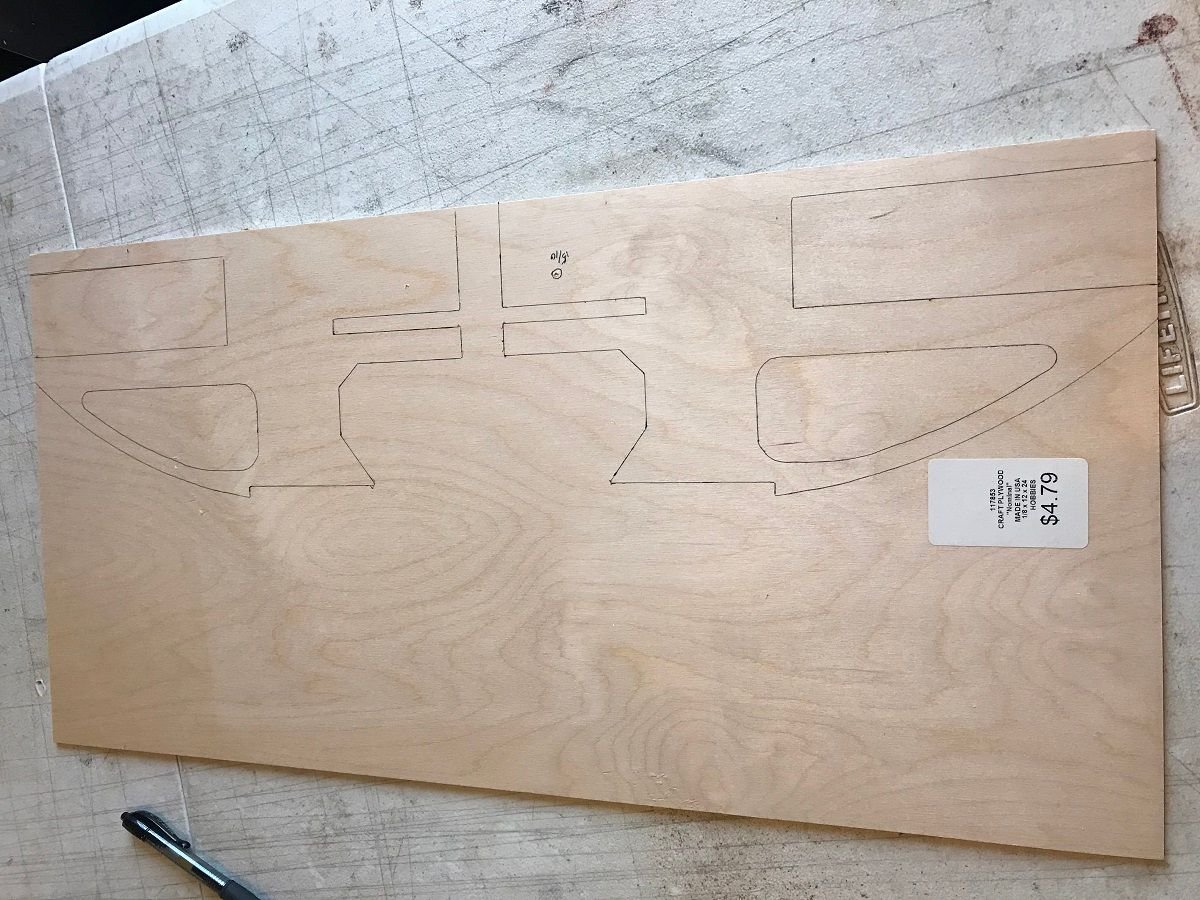

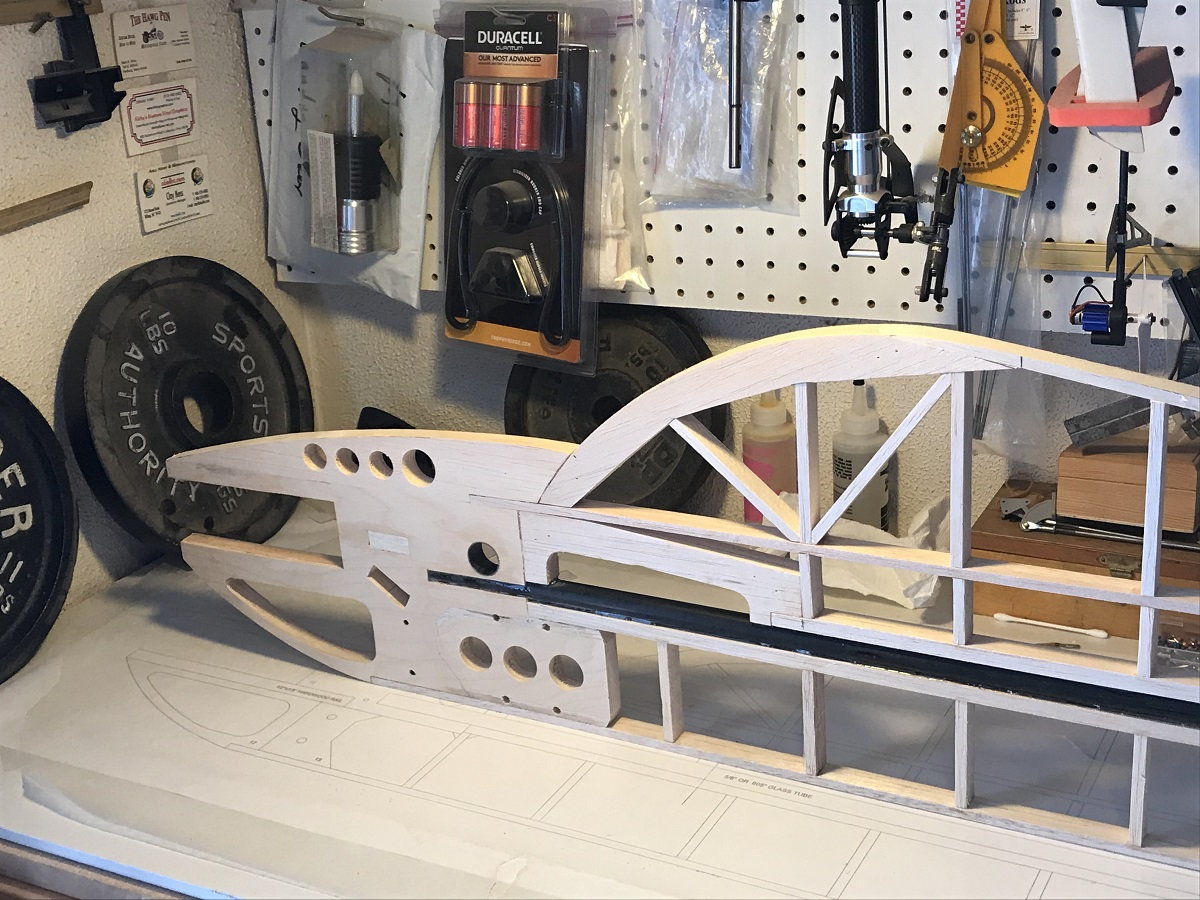

20cc Profile Edge 540 Build

#6

My Feedback: (9)

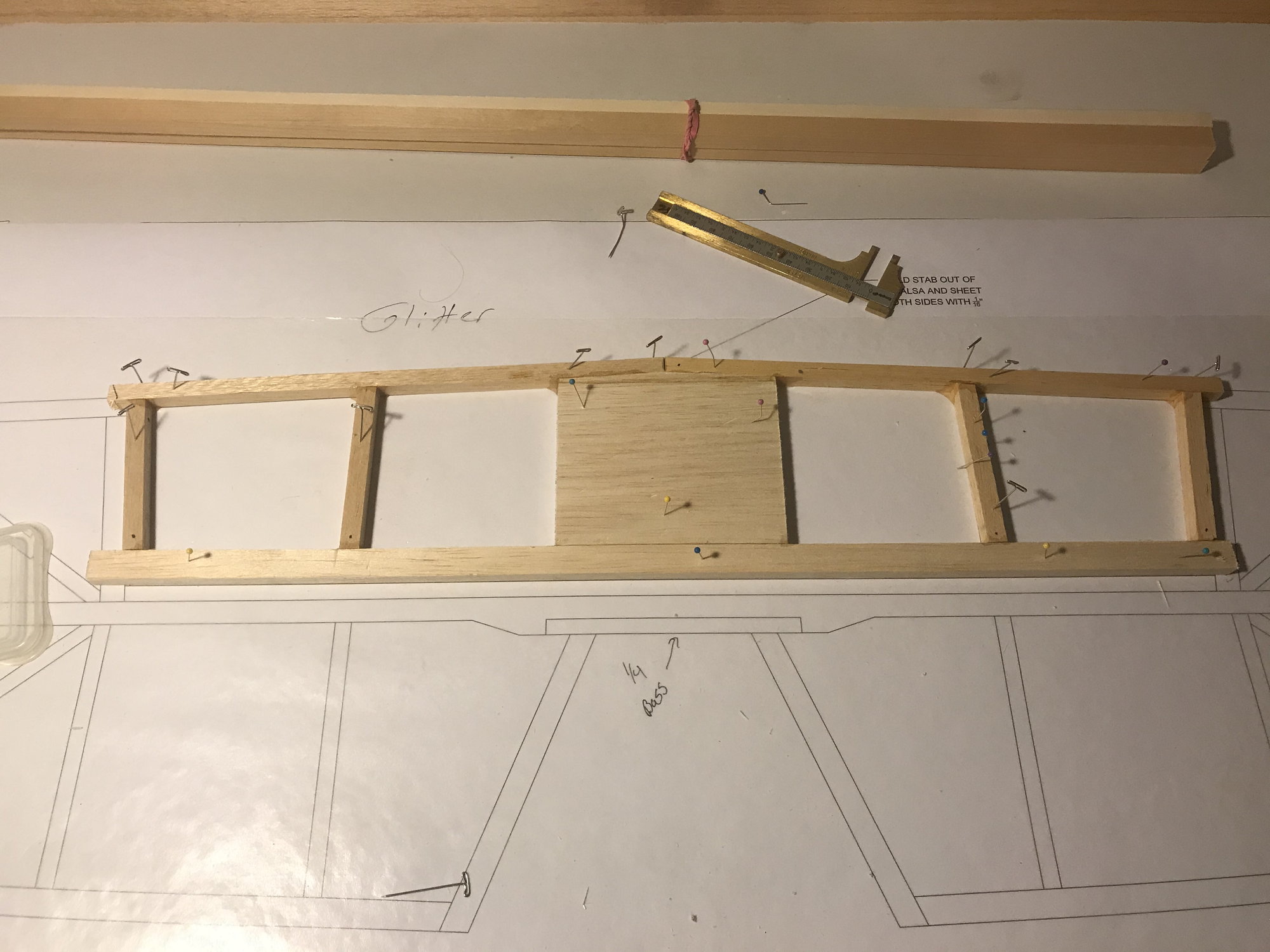

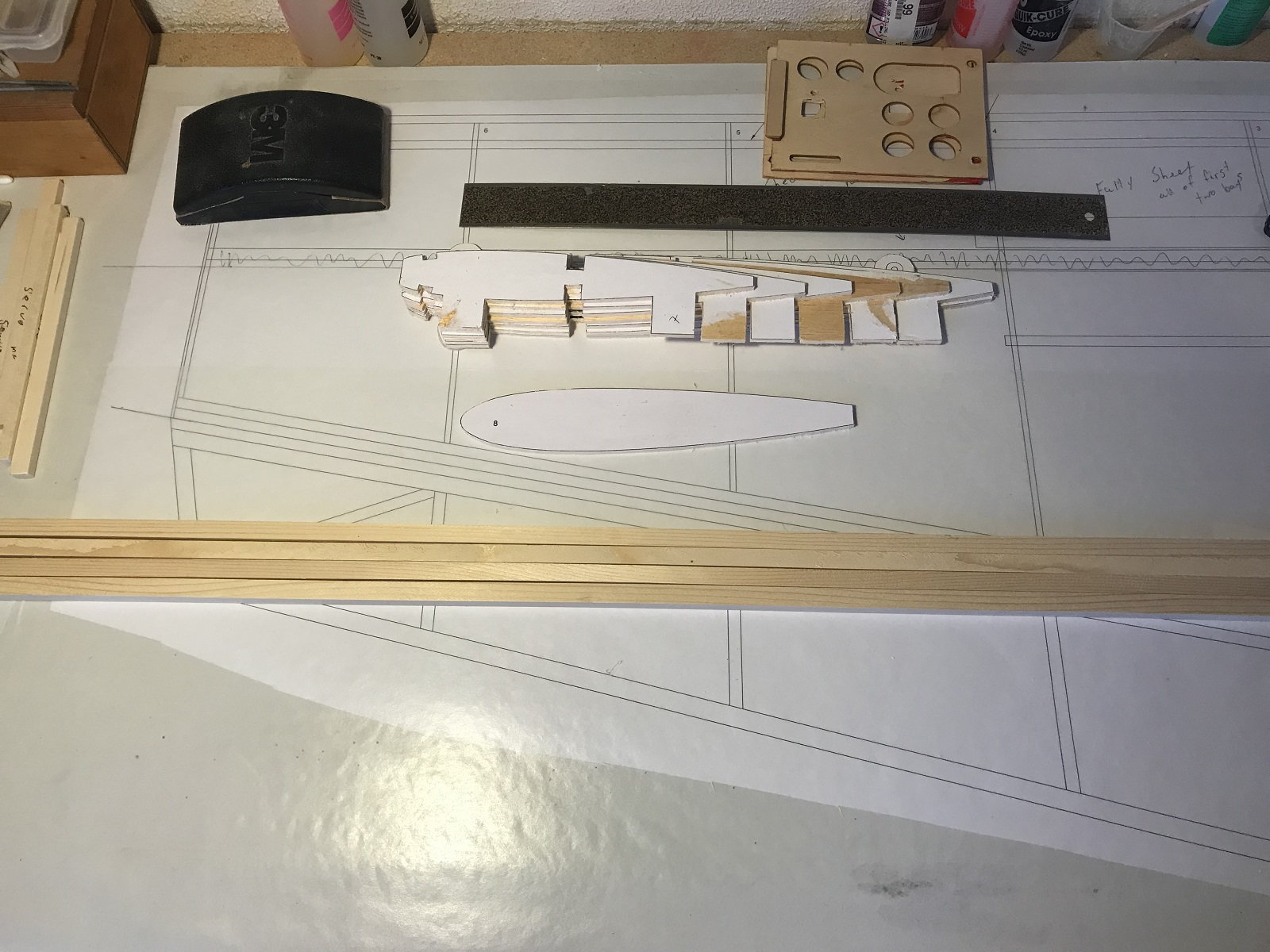

You do good work. If i may make a small suggestion without offending. On flat control surfaces I like to make a tiny holy in the hinge line to let the gasses out when you cover. That can be done later with a T pin, but putting a pin hole through your cross braces now will allow the gas to escape when shrinking the covering with only one exit hole in the hinge line.

David

David

#7

You do good work. If i may make a small suggestion without offending. On flat control surfaces I like to make a tiny holy in the hinge line to let the gasses out when you cover. That can be done later with a T pin, but putting a pin hole through your cross braces now will allow the gas to escape when shrinking the covering with only one exit hole in the hinge line.

David

David

#13

My Feedback: (9)

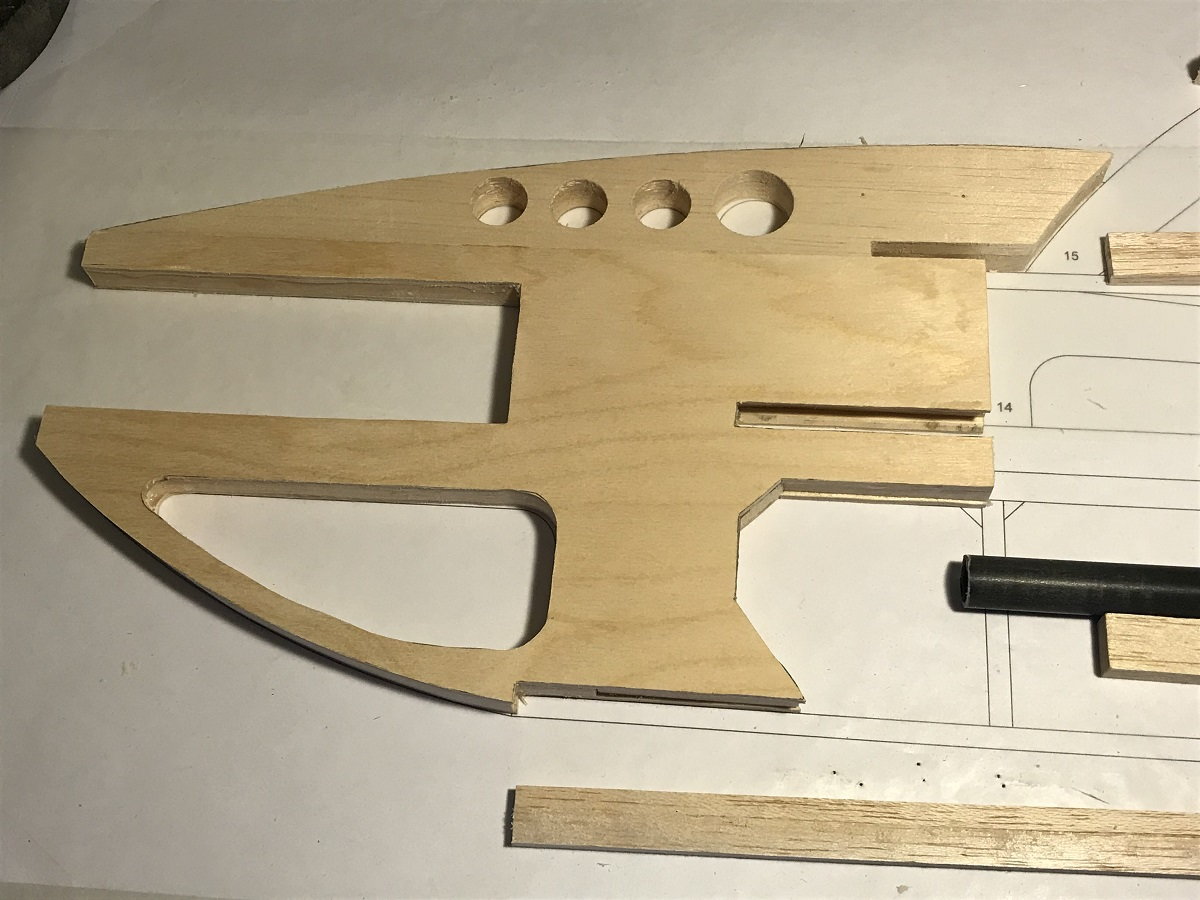

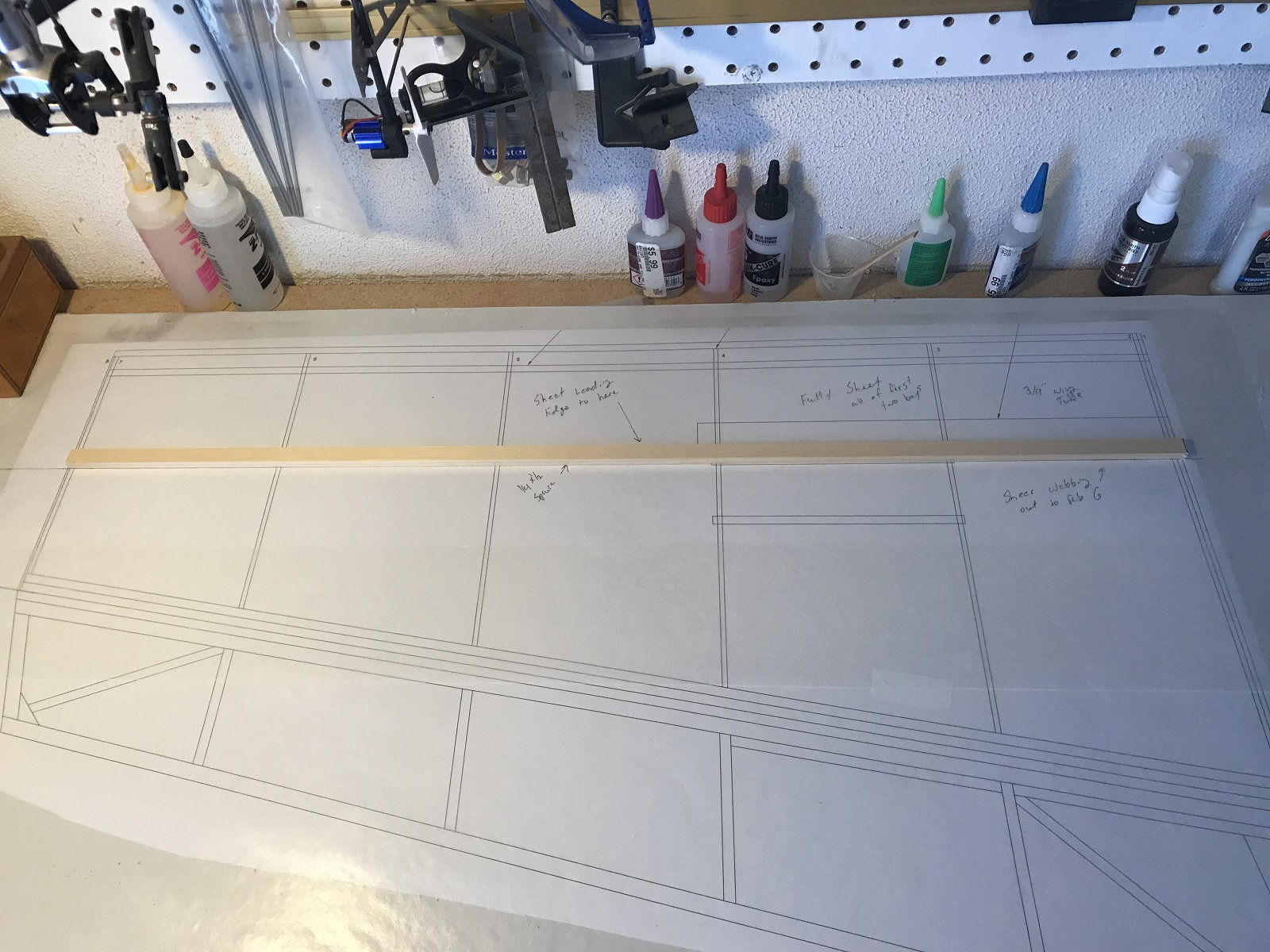

If you have not sheeted the other part of the wing. I would box in the servo opening and not just have the rails running parallel to the spars. This will make it stronger and make it easier to cover. I might even suggest moving the servo closer to one of the ribs for strength. Larger models were lost to flutter from not doing it that way.

david

david

#14

If you have not sheeted the other part of the wing. I would box in the servo opening and not just have the rails running parallel to the spars. This will make it stronger and make it easier to cover. I might even suggest moving the servo closer to one of the ribs for strength. Larger models were lost to flutter from not doing it that way.

david

david

#15

My Feedback: (9)

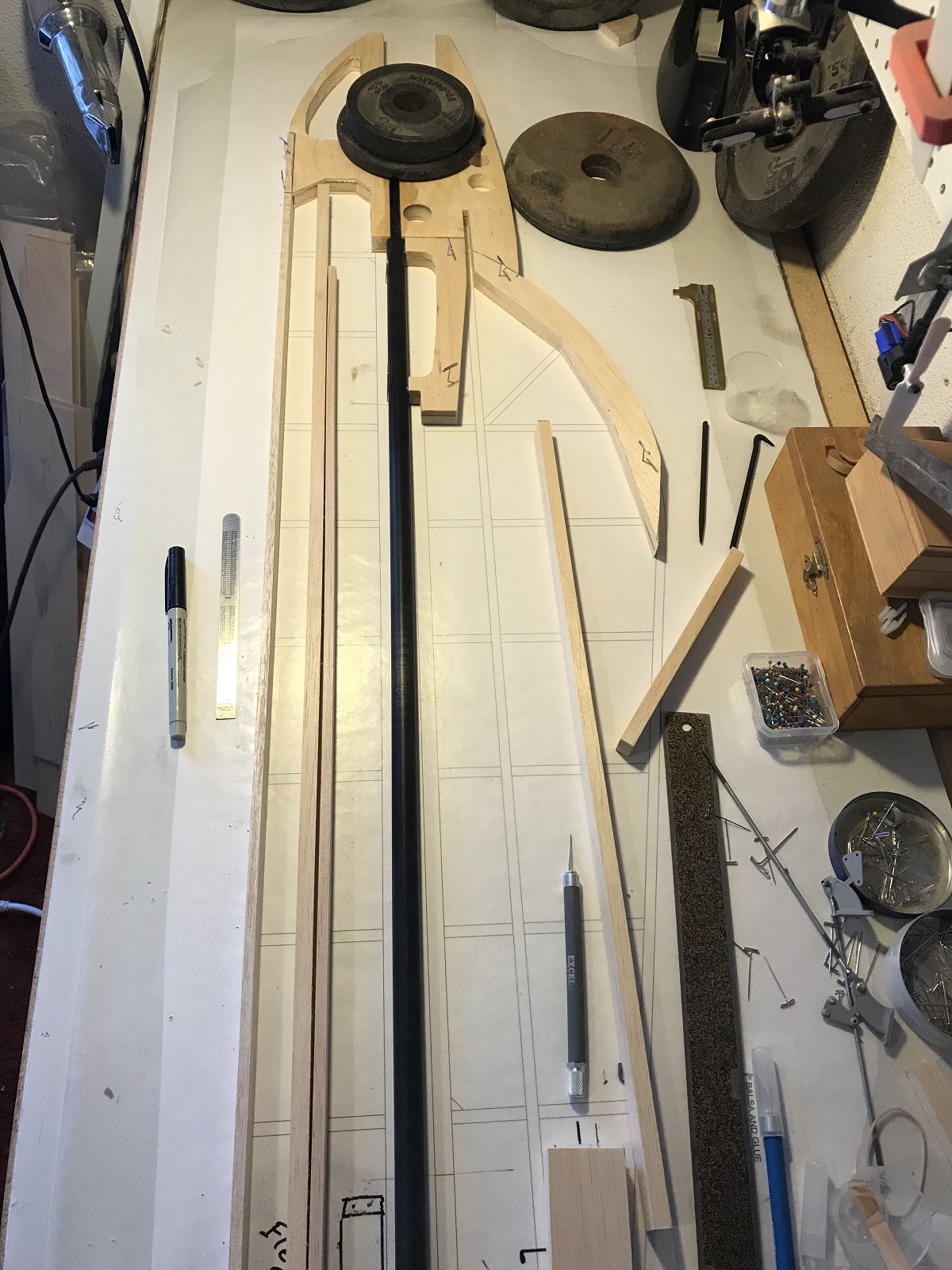

I am anxious to hear your flight report on it. My current profile is a 72" OMP Fusion. It's under powered with the DLE 20cc. The previous one I had was the 67" OMP Fusion. The 72" is a sturdier airframe but it's a lot heavier. It's going to need a 26cc from Valley view RC and then I'll "need" a airframe for the 20cc.

Keep up the good work, David

Keep up the good work, David

#16

I am anxious to hear your flight report on it. My current profile is a 72" OMP Fusion. It's under powered with the DLE 20cc. The previous one I had was the 67" OMP Fusion. The 72" is a sturdier airframe but it's a lot heavier. It's going to need a 26cc from Valley view RC and then I'll "need" a airframe for the 20cc.

Keep up the good work, David

Keep up the good work, David

The following users liked this post:

daveopam (06-13-2020)

#18

Join Date: Jan 2006

Location: Bartlesville,

OK

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

You do good work. If i may make a small suggestion without offending. On flat control surfaces I like to make a tiny holy in the hinge line to let the gasses out when you cover. That can be done later with a T pin, but putting a pin hole through your cross braces now will allow the gas to escape when shrinking the covering with only one exit hole in the hinge line.

David

David