brushed vs. brushless esc question

#1

Thread Starter

Join Date: Dec 2003

Location: Small Town,

VT

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

I know the esc's for brushed and brushless motors are different, but can someone explain why? What does the brushless esc do that the brushed esc does not? What is it that the brushless motors require that brushed motors do not? Excuse my ignorance. Thanks,

j

j

#2

Member

Join Date: Oct 2002

Location: lévis (quebec), QC

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

the bruhless motor have 3 wires and the esc control the motor by changing polarity on theses wires it dont change current intensity like brushed motor ecs but produce AC at the frequency you need to control rpm of the motor.

I not an expert thats just the way see that.

I not an expert thats just the way see that.

#3

Senior Member

Join Date: Jan 2004

Location: Earth, SINGAPORE

Posts: 565

Likes: 0

Received 0 Likes

on

0 Posts

Hi StrangeRanger

Brushed Motor and Brushless Motor is like Hub and Switch in Computer Network. Brushed Motor is just a normal motor where it work by direct current/voltage (We only focusing in DC area... NO AC Motor)

So to spin faster, u supply higher voltage.

In Brushless Motor (B/L for easy explaination), it work by propelling its magnet instead. I think i was derrive from Stepper motor technology. With that if you supply DC voltage, the motor will spin for 1 small step (or let say 120 degree) and just stop down there. To move further by another step, u need to energize another coil to push/pull the magnet. So for continuesly move the motor, it requires pulses of signal (just like stepper motor) Each of these pulse is lag by certain timing or phase. So to move faster, u shorten the timing or phase.

With that u will normally see at least 3 wires output for B/L motor (3 wires for 3 poles...therefore 120 degree movement per pole. It is also the minimum pole in order to work)

That is why Brushed Motor and Brushless Motor ESC is different.

I hope my explaination is correct or close to... it been very long time I study motor and stepper motor in my early education.

Super-Hornet

Brushed Motor and Brushless Motor is like Hub and Switch in Computer Network. Brushed Motor is just a normal motor where it work by direct current/voltage (We only focusing in DC area... NO AC Motor)

So to spin faster, u supply higher voltage.

In Brushless Motor (B/L for easy explaination), it work by propelling its magnet instead. I think i was derrive from Stepper motor technology. With that if you supply DC voltage, the motor will spin for 1 small step (or let say 120 degree) and just stop down there. To move further by another step, u need to energize another coil to push/pull the magnet. So for continuesly move the motor, it requires pulses of signal (just like stepper motor) Each of these pulse is lag by certain timing or phase. So to move faster, u shorten the timing or phase.

With that u will normally see at least 3 wires output for B/L motor (3 wires for 3 poles...therefore 120 degree movement per pole. It is also the minimum pole in order to work)

That is why Brushed Motor and Brushless Motor ESC is different.

I hope my explaination is correct or close to... it been very long time I study motor and stepper motor in my early education.

Super-Hornet

#4

Senior Member

Join Date: Jan 2003

Location: Raleigh, NC

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

Brushless motors are three phase motors. They require a ESC that can rotate 240 degrees, thus the three wires instead of two,as in a brushed ESC.

#5

Senior Member

Join Date: Oct 2003

Location: Mosinee,

WI

Posts: 1,185

Likes: 0

Received 0 Likes

on

0 Posts

A brushless DC motor is basically an AC 3 Phase induction motor. The only difference between the two is a brushless DC motor has a permanent magnet rotor and an AC induction motor has an armature made of laminated metal stampings. The principal is the same. The 3 stator windings (stationary windings on the inside of the can) are switched on and off in such a way that a rotating magnetic field is created which reacts with the armature to cause the armature to turn.

Because of these difference the ESC's are vastly different. An ESC for a brushed motor is basically a variable DC source. The brushless DC ESC has to create a variable frequency, variable amplitude 3 phase AC voltage. There's a lot more circuitry and lofgic involved.

I'm a technician who works on industrial electronic eqipment for a living. The fact that we have such small 3 phase controllers as this is nothing short of a miracle. The smallest AC variable frquency drives I've ever seen are many times larger and more expensive than what we have in the model arena.

Regards,

Mike

Because of these difference the ESC's are vastly different. An ESC for a brushed motor is basically a variable DC source. The brushless DC ESC has to create a variable frequency, variable amplitude 3 phase AC voltage. There's a lot more circuitry and lofgic involved.

I'm a technician who works on industrial electronic eqipment for a living. The fact that we have such small 3 phase controllers as this is nothing short of a miracle. The smallest AC variable frquency drives I've ever seen are many times larger and more expensive than what we have in the model arena.

Regards,

Mike

#6

Senior Member

Join Date: Jan 2004

Location: Earth, SINGAPORE

Posts: 565

Likes: 0

Received 0 Likes

on

0 Posts

Hi ChopperMike

I think our Brushless works in Square wave or ractangular pulses instead of AC. I not sure yet because I haven't plug it to Oscilloscope. If you use Square wave pulse, it is much easier to produce than AC (Sinusoidal) wave. With microcontroller, ADC, DAC, MOSFET, you can produce a simple B/L controller.

In AC B/L, the metal stamping u mention I think is Aluminium. Why? Well, Aluminium will reach to moving magnet (or vise versas) to produce a mirror effect of the magnetic field. That is why it can propel itself to move.

Super-Hornet

I think our Brushless works in Square wave or ractangular pulses instead of AC. I not sure yet because I haven't plug it to Oscilloscope. If you use Square wave pulse, it is much easier to produce than AC (Sinusoidal) wave. With microcontroller, ADC, DAC, MOSFET, you can produce a simple B/L controller.

In AC B/L, the metal stamping u mention I think is Aluminium. Why? Well, Aluminium will reach to moving magnet (or vise versas) to produce a mirror effect of the magnetic field. That is why it can propel itself to move.

Super-Hornet

#7

Thread Starter

Join Date: Dec 2003

Location: Small Town,

VT

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Ok guys, thanks for the replys. But let me sum it up for myself in a very basic way that I think I understand  Brushed esc's basically just control voltage, or amount of current flow. More flow = more speed. Nothing too impressive there. A brushLESS controller sounds pretty much like a constant voltage or flow, but alters the delivered frequency of an AC current. Higher freq. = higher speed but w/ basically the same current flow. Is that about right??

Brushed esc's basically just control voltage, or amount of current flow. More flow = more speed. Nothing too impressive there. A brushLESS controller sounds pretty much like a constant voltage or flow, but alters the delivered frequency of an AC current. Higher freq. = higher speed but w/ basically the same current flow. Is that about right??

Ok, this leads to another question then....what are the advantages of a brushless set up then? Are the motors that much more powerful? Do the really deliver that much more torque? Or is it basically a longevity issue. Do the brushless set ups just last and last?

I'm just trying to figure out why everyone raves about brushless set ups when it costs sooo much more to get into them. Thanks guys,

j

ps: remember...i'm an idiot, so don't get to technical on me. I understand basic electronics, know what components do (I sell them for a living) and can solder, but that's aobut it

Brushed esc's basically just control voltage, or amount of current flow. More flow = more speed. Nothing too impressive there. A brushLESS controller sounds pretty much like a constant voltage or flow, but alters the delivered frequency of an AC current. Higher freq. = higher speed but w/ basically the same current flow. Is that about right??

Brushed esc's basically just control voltage, or amount of current flow. More flow = more speed. Nothing too impressive there. A brushLESS controller sounds pretty much like a constant voltage or flow, but alters the delivered frequency of an AC current. Higher freq. = higher speed but w/ basically the same current flow. Is that about right??Ok, this leads to another question then....what are the advantages of a brushless set up then? Are the motors that much more powerful? Do the really deliver that much more torque? Or is it basically a longevity issue. Do the brushless set ups just last and last?

I'm just trying to figure out why everyone raves about brushless set ups when it costs sooo much more to get into them. Thanks guys,

j

ps: remember...i'm an idiot, so don't get to technical on me. I understand basic electronics, know what components do (I sell them for a living) and can solder, but that's aobut it

#8

Senior Member

Join Date: Jan 2004

Location: Earth, SINGAPORE

Posts: 565

Likes: 0

Received 0 Likes

on

0 Posts

Hi StrangeRanger...

Another way to explain this:

Brushed Motor:

Speed => Changes in voltage

Torque => Changes in current

Brushed Controller or ESC:

Voltage variation => Changes in duty cycle.

Current => Practically linear to Voltage changes.

To change voltage value, one way is to use PWD (Pulsed Width Modulation). 0% Cycle or flatline.. No voltage. 40% Cycle means in one cycle, it has 40% High (Full power from battery) and 60% flatline. (0 Volt). To add up, it is about 40% of total voltage of the battery. 50% Cycle means 50 percent high and 50% low. 100% Cycle means always high (Just like connecting to battery directly)

Why B/L motor better... It is more efficient than Brushed. All the energy (simple assumption) is converted to moving shaft. In Brushed, some energy is wasted in friction cause by brushes contact and resistance it produce. Some energy also wasted in sparks.

In B/L motor, in proper usage, the only wear and tear will be the bearing. In Brushed motor, wear and tear is brushes, commutator and bearing or brash bushing.

Super-Hornet

Another way to explain this:

Brushed Motor:

Speed => Changes in voltage

Torque => Changes in current

Brushed Controller or ESC:

Voltage variation => Changes in duty cycle.

Current => Practically linear to Voltage changes.

To change voltage value, one way is to use PWD (Pulsed Width Modulation). 0% Cycle or flatline.. No voltage. 40% Cycle means in one cycle, it has 40% High (Full power from battery) and 60% flatline. (0 Volt). To add up, it is about 40% of total voltage of the battery. 50% Cycle means 50 percent high and 50% low. 100% Cycle means always high (Just like connecting to battery directly)

Why B/L motor better... It is more efficient than Brushed. All the energy (simple assumption) is converted to moving shaft. In Brushed, some energy is wasted in friction cause by brushes contact and resistance it produce. Some energy also wasted in sparks.

In B/L motor, in proper usage, the only wear and tear will be the bearing. In Brushed motor, wear and tear is brushes, commutator and bearing or brash bushing.

Super-Hornet

#9

Senior Member

Join Date: Oct 2003

Location: Mosinee,

WI

Posts: 1,185

Likes: 0

Received 0 Likes

on

0 Posts

You're right. Any ESC, brushless or brushed, uses square wave pulses. In brushed DC ESC's you pulse the motor with the full voltage of the battery on and off in such a way that the voltage that the motor sees is varied. This is called PWM or Pulse width Modulation. The duty cycle, or on versus off times, are varied to produce a certain effective DC level. This is used quite a bit in motion control and power supplies. The reason is simple. A transistor, FET or Bipolar, produces much less heat when it's turned on fully (digital) than not (analog). It's the same principal with the brushless ESC's. You turn on the transistors in such a way that the sine wave is simulated. Since the switching frequency is so high, the motor doesn't know the difference. The higher the switching frquency the better.

The reason these motors use a permanent magnet rotor is efficiency. With a AC induction motor a certain amount of current in the stator windings is used to magnetize the rotor, to produce an opposing magnetic field for the stator to push against. With the smaller size motors it's more efficient to use a permanent magnet to accomplish this. In industry you don't see large brushless DC motors, they're all AC Vector induction motors. In fact, these days you don't see brushless DC motors used much except as servo motors (which are generally smaller motors, maybe 10 HP or less) since the introduction of AC Vector.

Mike

The reason these motors use a permanent magnet rotor is efficiency. With a AC induction motor a certain amount of current in the stator windings is used to magnetize the rotor, to produce an opposing magnetic field for the stator to push against. With the smaller size motors it's more efficient to use a permanent magnet to accomplish this. In industry you don't see large brushless DC motors, they're all AC Vector induction motors. In fact, these days you don't see brushless DC motors used much except as servo motors (which are generally smaller motors, maybe 10 HP or less) since the introduction of AC Vector.

Mike

#10

Junior Member

Join Date: Oct 2011

Location: Nixa, MO

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

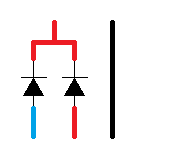

I haven't tested this theory yet, but I would assume (with my somewhat limited knowledge of electronics, and having seen the response of a brushed motor on a brushless ESC) that the brushless ESC and motors are set up with a 2-phase alternating current. This would mean that the blue and red wires are always positive alternating on and off, and the black wire is always a ground. I'm going to test my theory tonight, but I believe placing a diode on the incoming blue and red leads to prevent them from shorting back on themselves would be an easy conversion from brushless to brushed without adding any significant weight, and without having to buy a different ESC. I'll update this thread if it works (or not). The final wiring would look like:

Note: If you're going to try this for yourself before I post results up here, I'd suggest you make a set of "jumper" leads to do it with; absolutely don't cut the leads off your ESC for it, as that will likely make your ESC useless for brushless application later, and you'll likely find yourself cutting them off again later. If it works, I would build the diodes into the motor leads, as the motor will then work with either a brushless or bushed ESC (providing my theory is right). To hook a brushed ESC to it later, just only use one of the leads for your positive input, and leave the other hanging (the diode will prevent it from shorting on anything).

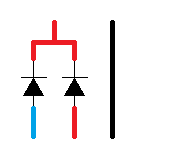

As an alternate theory, just in case it is a 3-phase with all wires alternating between positive and negative, a series of 6 diodes should also level the current, which I will try if the 2 diode system fails to work as expected. The 6 diode system would be a lot more complex, but still totally do-able, and still while adding only an insignificant amount of weight. The 6 diode system's wiring would look something more like:

If someone's already tried this, and found that it doesn't work, and wants to save me some time, please feel free!

<br type="_moz" />

Note: If you're going to try this for yourself before I post results up here, I'd suggest you make a set of "jumper" leads to do it with; absolutely don't cut the leads off your ESC for it, as that will likely make your ESC useless for brushless application later, and you'll likely find yourself cutting them off again later. If it works, I would build the diodes into the motor leads, as the motor will then work with either a brushless or bushed ESC (providing my theory is right). To hook a brushed ESC to it later, just only use one of the leads for your positive input, and leave the other hanging (the diode will prevent it from shorting on anything).

As an alternate theory, just in case it is a 3-phase with all wires alternating between positive and negative, a series of 6 diodes should also level the current, which I will try if the 2 diode system fails to work as expected. The 6 diode system would be a lot more complex, but still totally do-able, and still while adding only an insignificant amount of weight. The 6 diode system's wiring would look something more like:

If someone's already tried this, and found that it doesn't work, and wants to save me some time, please feel free!

<br type="_moz" />

#11

Junior Member

Join Date: Oct 2011

Location: Nixa, MO

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

The second method I mentioned works swimmingly. Make sure you get diodes that can handle the appropriate amperage, or they'll overheat and melt through pretty much anything around them. In other words, you can't use 1000V/1.5A diodes for an 11.1V/30A ESC. You'll need diodes that can handle 30 amps for a 30 amp ESC. Also, don't shoot for a 600V/30A diode if you can find anything else, the closest to the proper voltage and amperage you can get is best. Mouser sells a rectifier diode that's rated 30V/30A that would be well suited for the task. The problem with getting the higher voltage diodes is that they will reduce your voltage. The 1000V diodes that I have here won't even let the motor spin up due to voltage drop.

#12

Member

Join Date: Nov 2011

Location: ShenzhenGuangdong Province, CHINA

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Just know brushless motors are better than brush ones, do not know these lots of things, nice questions, nice answers!