Skygate/CARF Viperjet

#726

Oops. I have seen that once before, yes factory has flipped the mount. It is possible to cut the servo opening wider to drop the servo. A 3/4” Razor saw blade will work. Servo position does need to match.

Dave

Dave

The following users liked this post:

DenisFerrari (11-01-2024)

#728

Senior Member

Carf should be compensating you somehow with these mess ups IMO. Check your parts bags for the wing bolts. They are 5mm I believe. Mine were so short, they wouldn't even reach the fuselage blind nut. Had to run to Home Depot to pick some up as I didn't have any. 35mm I believe is what works.

#729

6mm. I have been involved with a lot of Vipers over the years and problems are rare.

For me I would quite like the wheel openings to be left. They can then be cut to suit the wheels/legs exactly. But, certainly this is not normal. As always, the Sales Rep you used is there to help. Although I know most of the US reps are at JetPower this weekend, they will still help.

For me I would quite like the wheel openings to be left. They can then be cut to suit the wheels/legs exactly. But, certainly this is not normal. As always, the Sales Rep you used is there to help. Although I know most of the US reps are at JetPower this weekend, they will still help.

#730

Senior Member

6mm. I have been involved with a lot of Vipers over the years and problems are rare.

For me I would quite like the wheel openings to be left. They can then be cut to suit the wheels/legs exactly. But, certainly this is not normal. As always, the Sales Rep you used is there to help. Although I know most of the US reps are at JetPower this weekend, they will still help.

For me I would quite like the wheel openings to be left. They can then be cut to suit the wheels/legs exactly. But, certainly this is not normal. As always, the Sales Rep you used is there to help. Although I know most of the US reps are at JetPower this weekend, they will still help.

#731

My Feedback: (1)

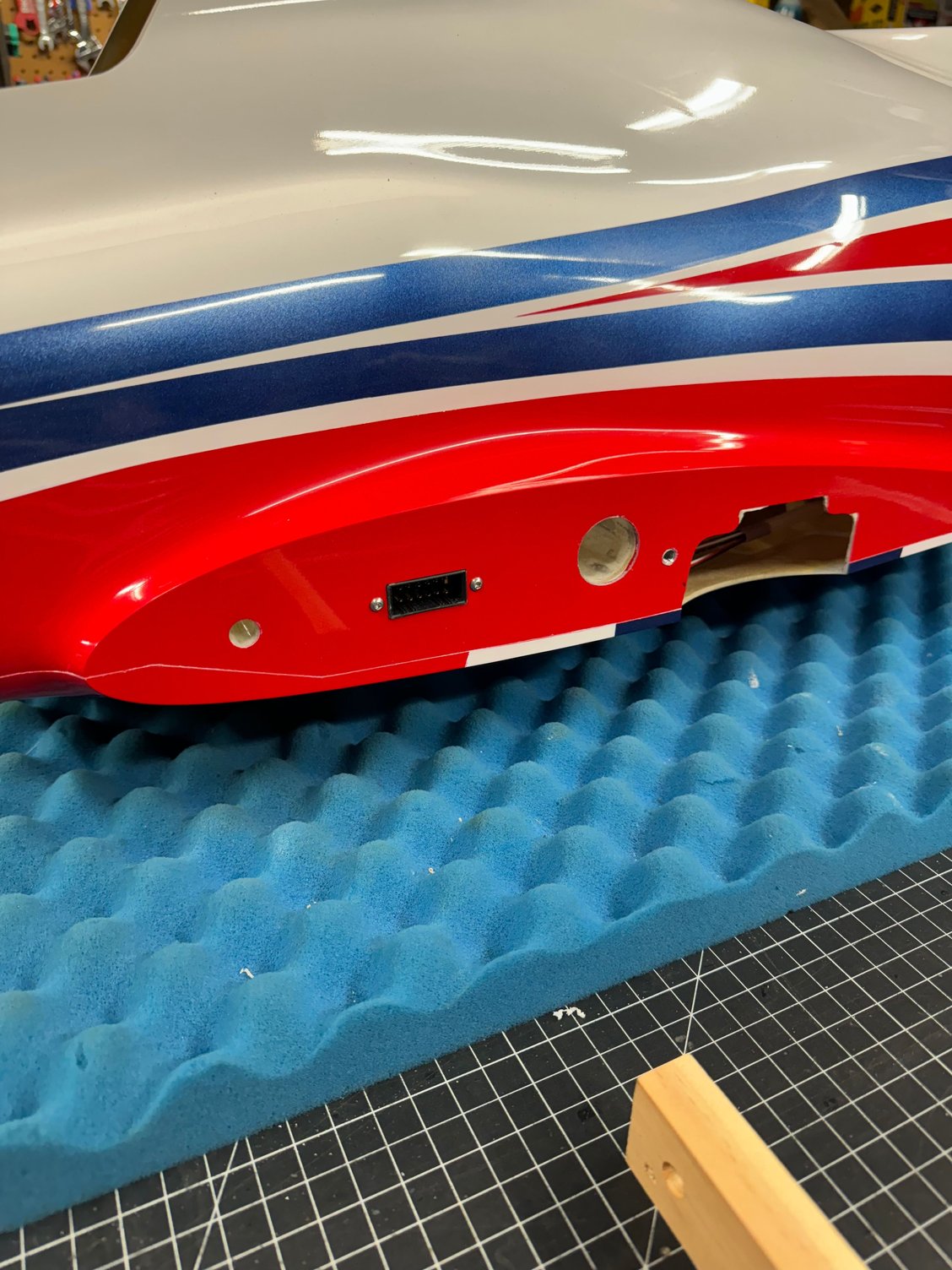

My local CARF rep is awesome and he offered to fix things himself. I have a builder friend that is much better at making the cutouts than I am and he agreed to help making the holes in the fuselage.

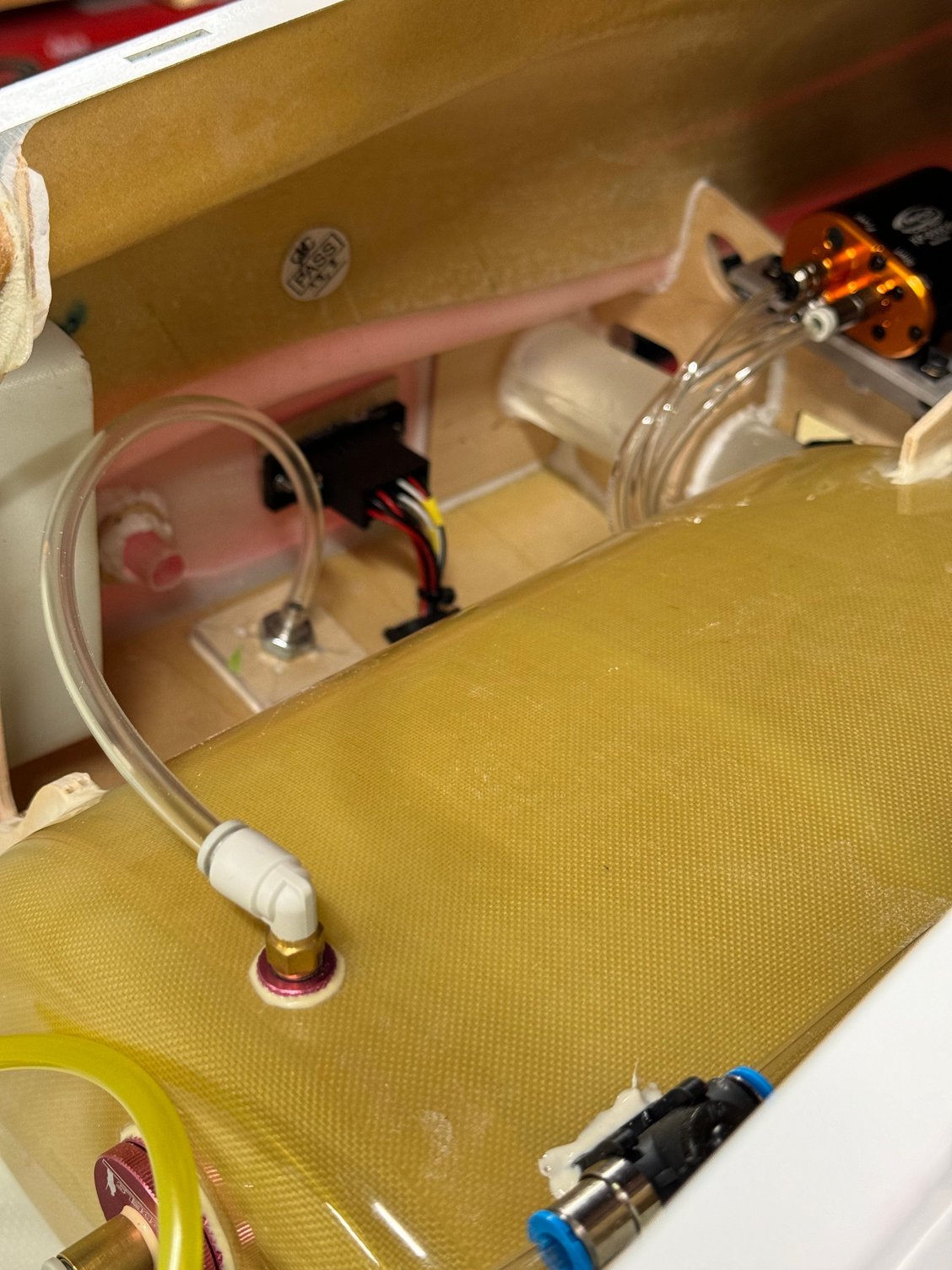

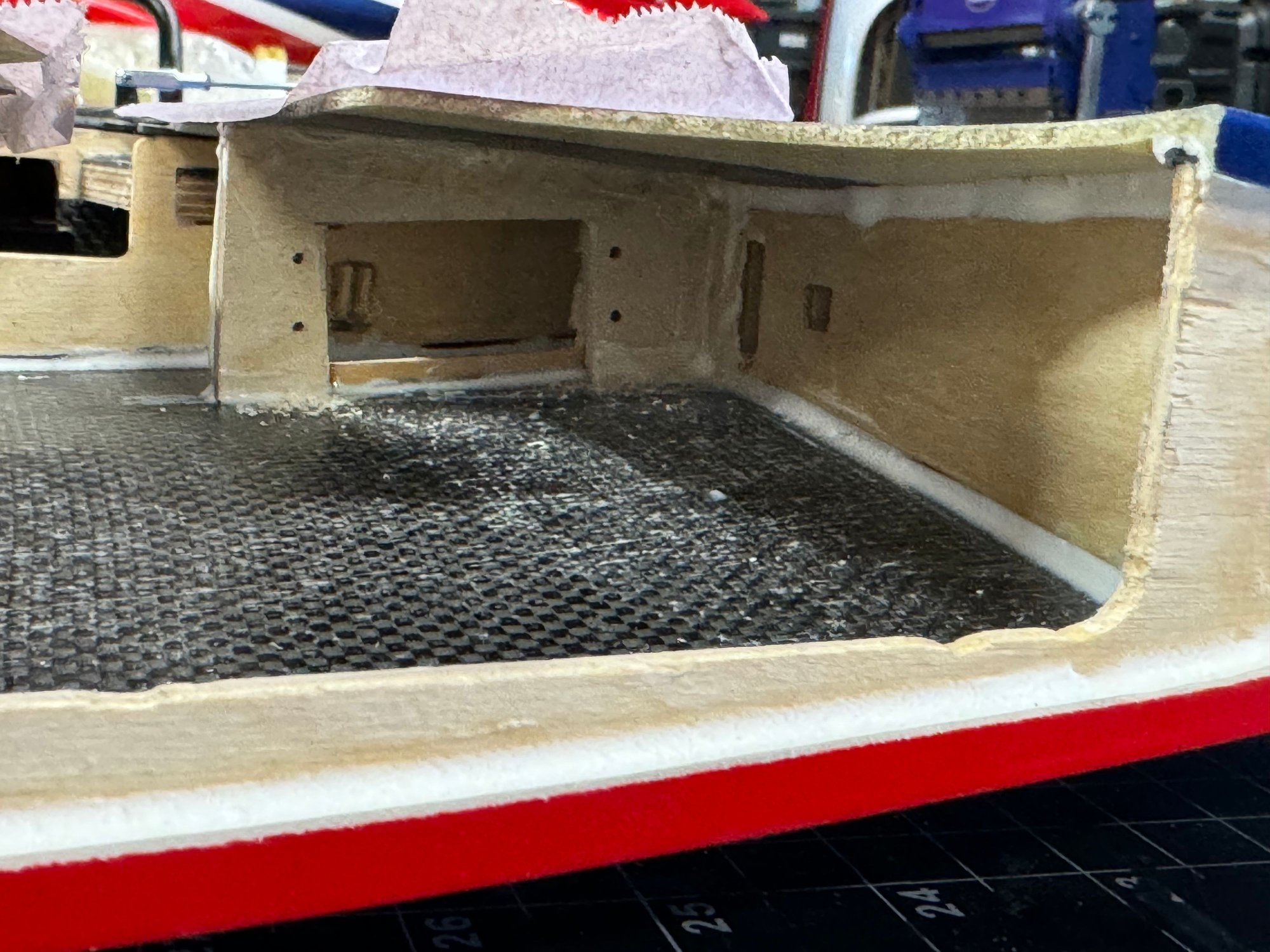

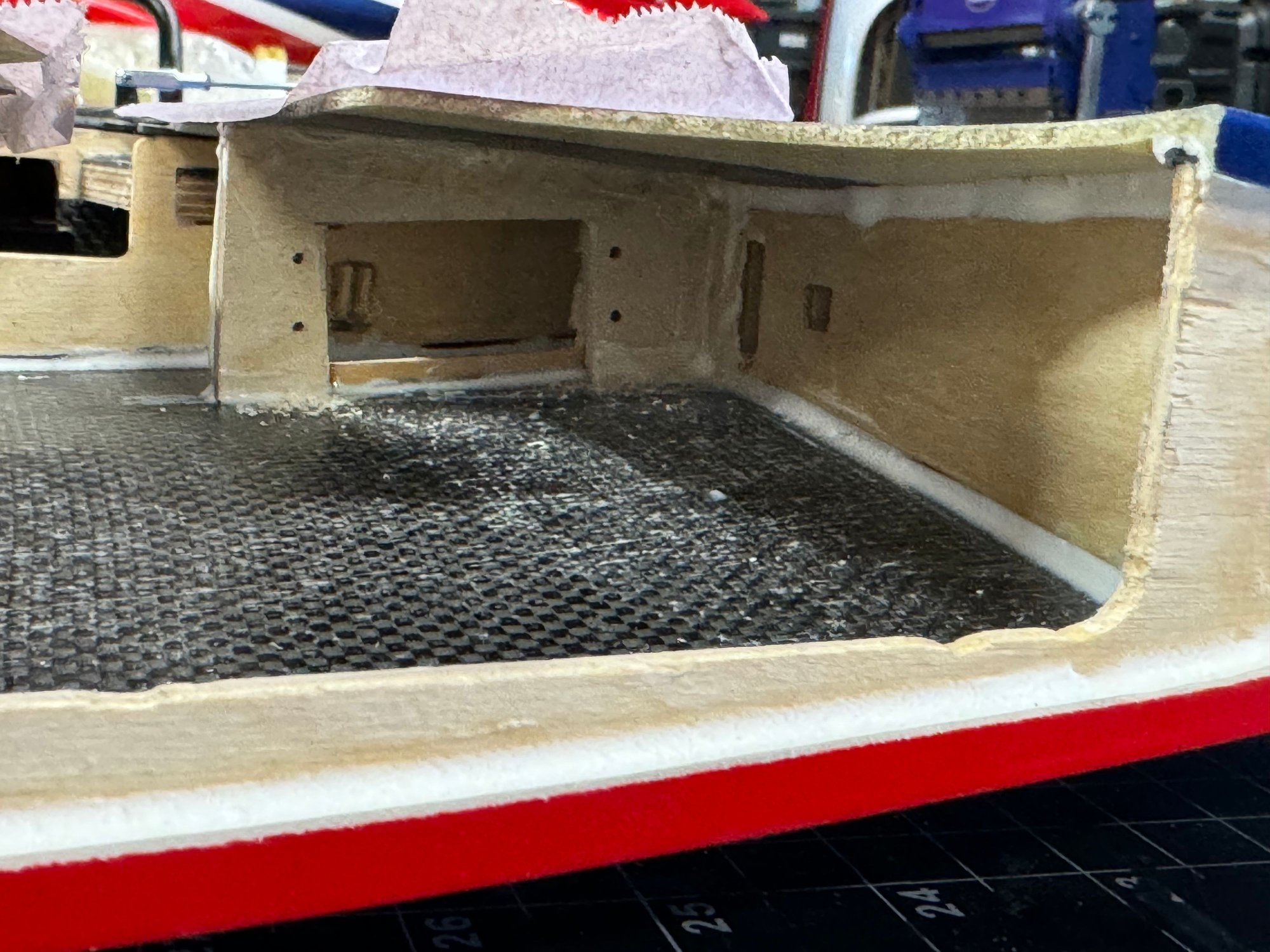

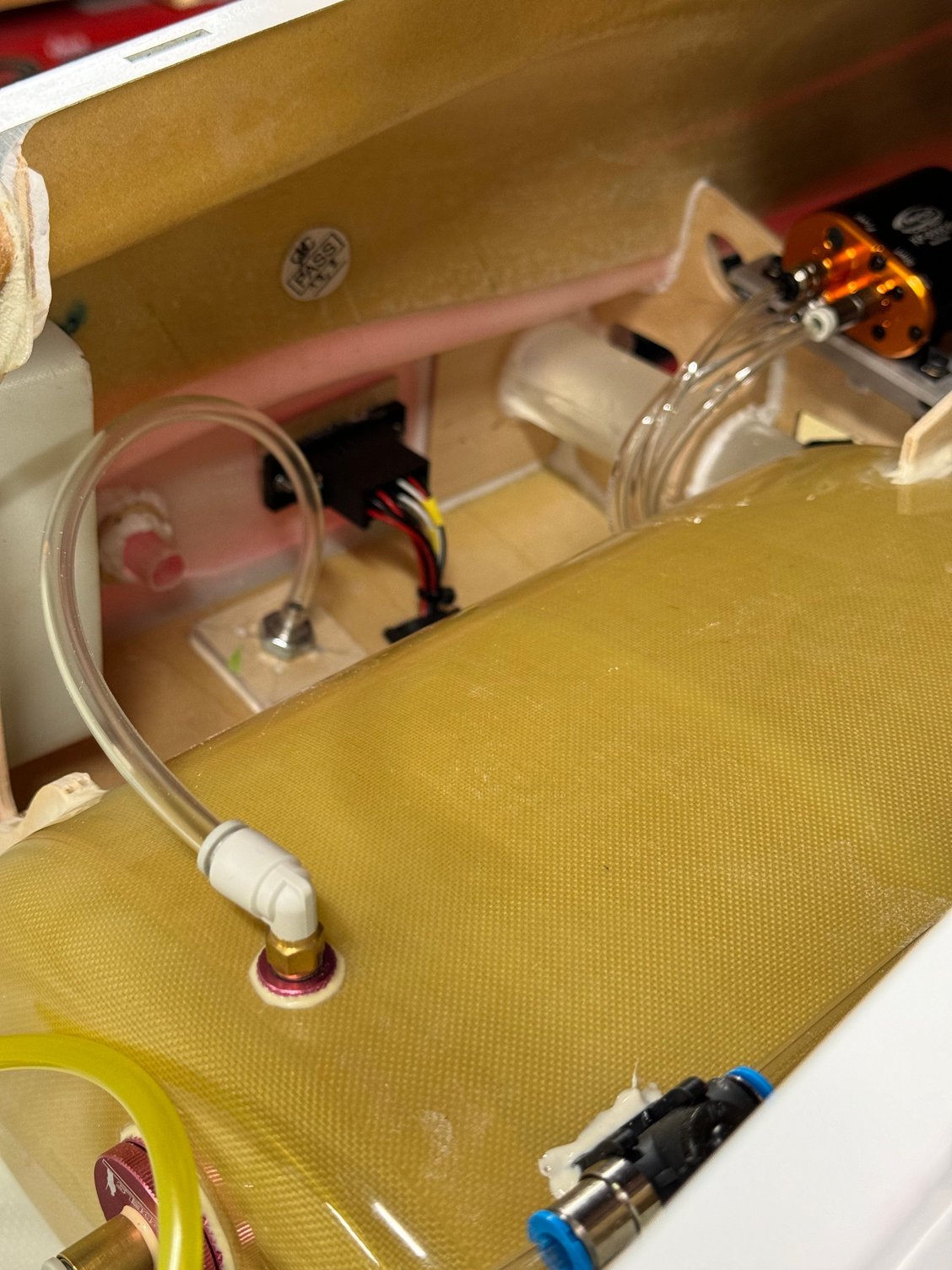

I fixed the servo mount and moving on to getting the landing gear mounted. The flap servos needed a 1/8" (3mm) spacer to have the arm line up with the horns of the surface. So, I made a plywood plate to fill the opening and epoxied it in place. If anyone else needs to do this, here is a tip - drill the servo mounting holes before you glue the plywood in. Now left and right wings are slightly different and my OCD will have to deal with it.

The QC stickers put all over the model are a joke. It is like buying a four door car and it only having 3-doors when it is delivered to you

I fixed the servo mount and moving on to getting the landing gear mounted. The flap servos needed a 1/8" (3mm) spacer to have the arm line up with the horns of the surface. So, I made a plywood plate to fill the opening and epoxied it in place. If anyone else needs to do this, here is a tip - drill the servo mounting holes before you glue the plywood in. Now left and right wings are slightly different and my OCD will have to deal with it.

The QC stickers put all over the model are a joke. It is like buying a four door car and it only having 3-doors when it is delivered to you

The following 2 users liked this post by jvaliensi:

DenisFerrari (10-27-2024),

Zstanman (10-31-2024)

#734

Junior Member

I just ordered the Unilight set that was on the accessories list for this jet. They should be here any day. Just started my build of this jet so I would love to see more of your pics as you proceed through your build.

#735

My Feedback: (1)

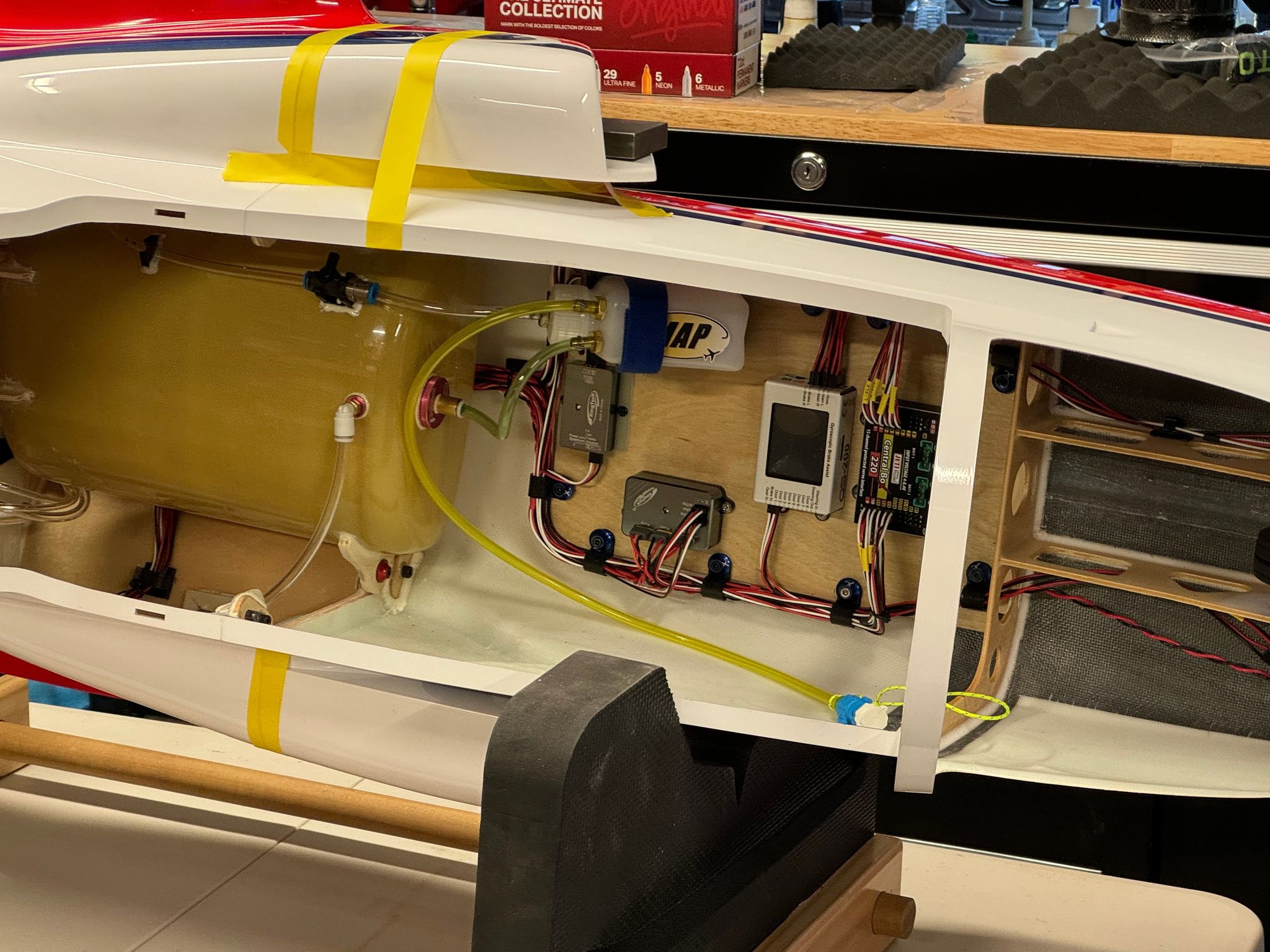

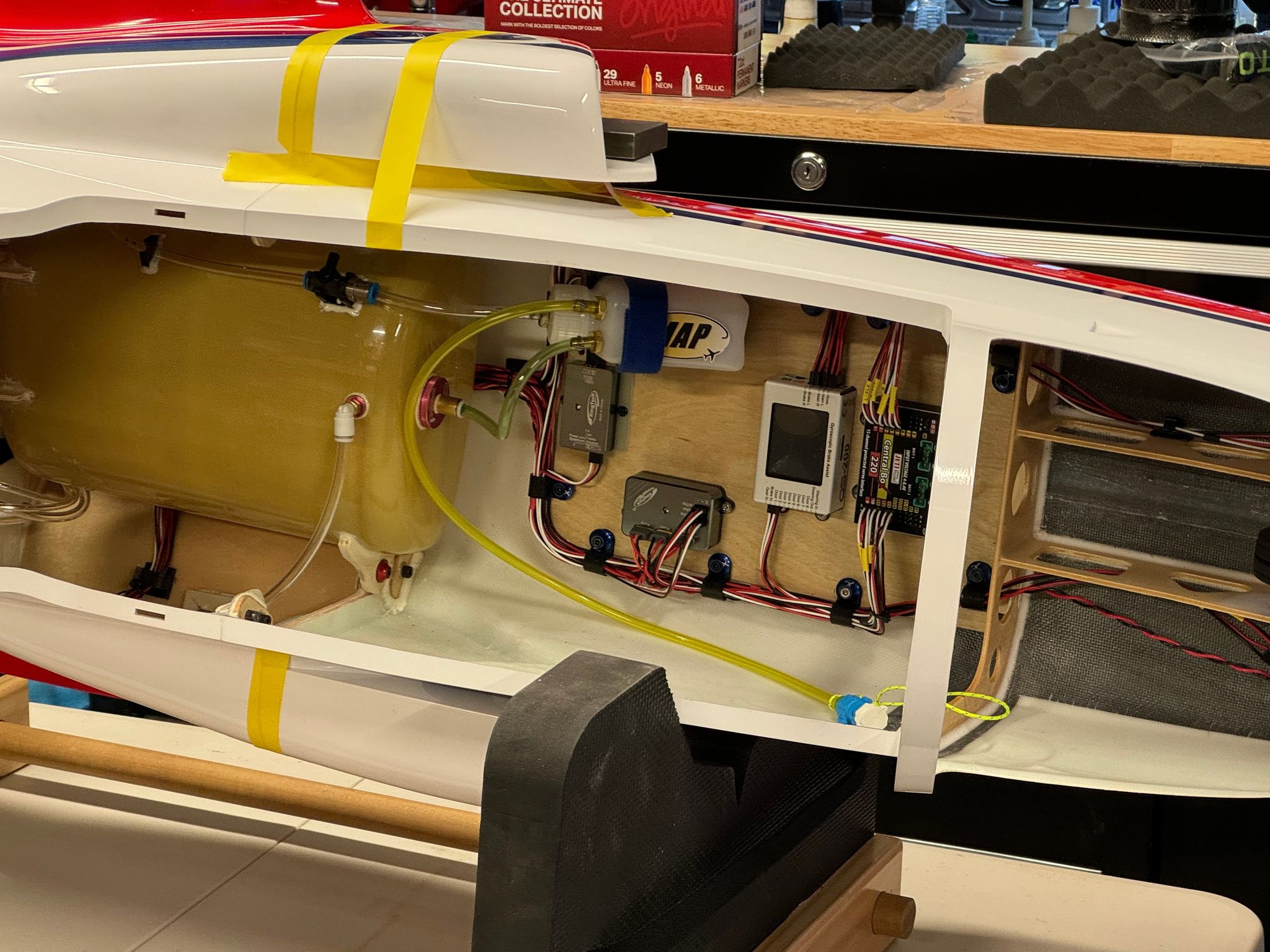

No mater how much I work on this airplane it always feels like there is 90% of it left to do. It is been a fun project so far.

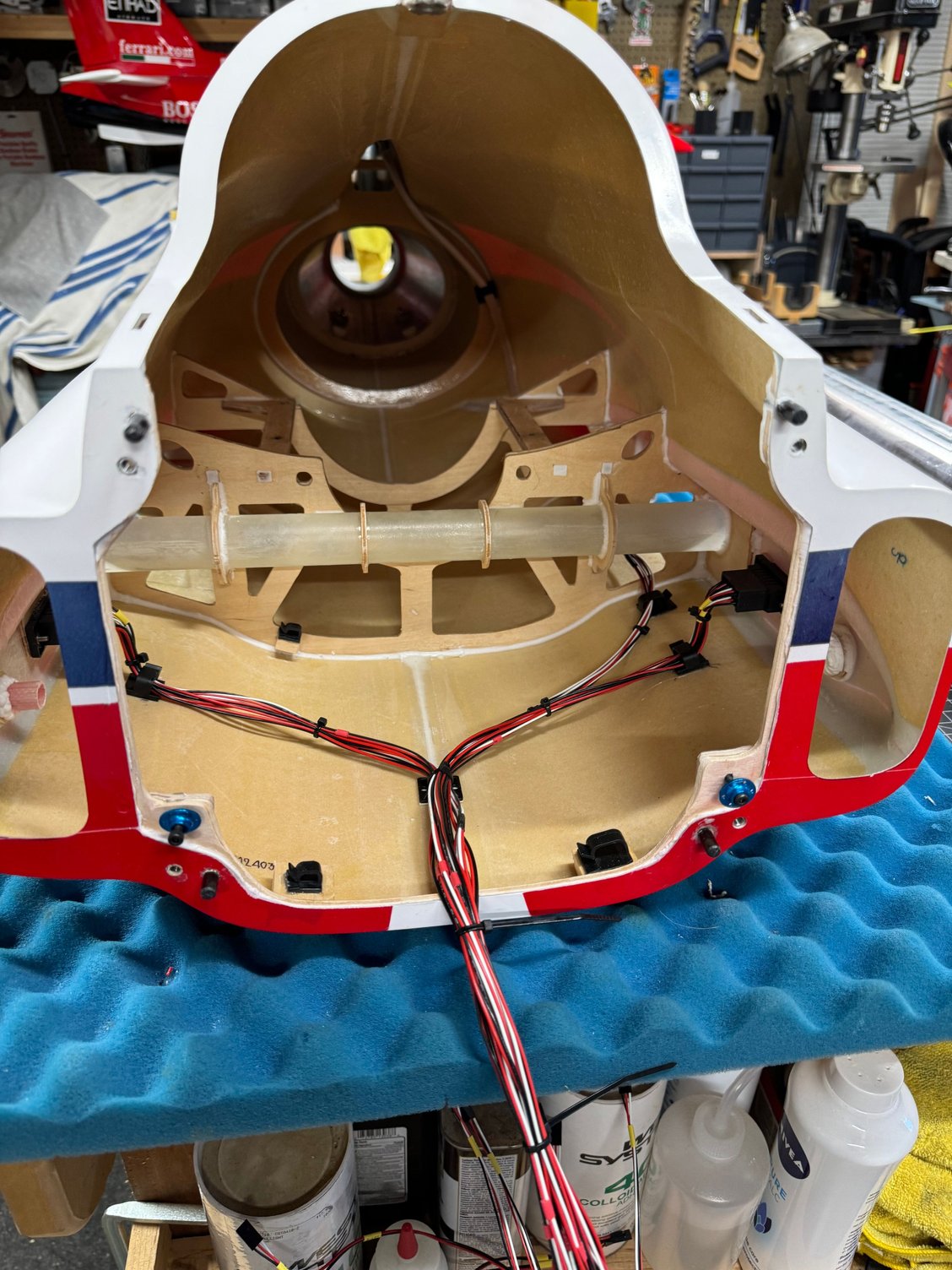

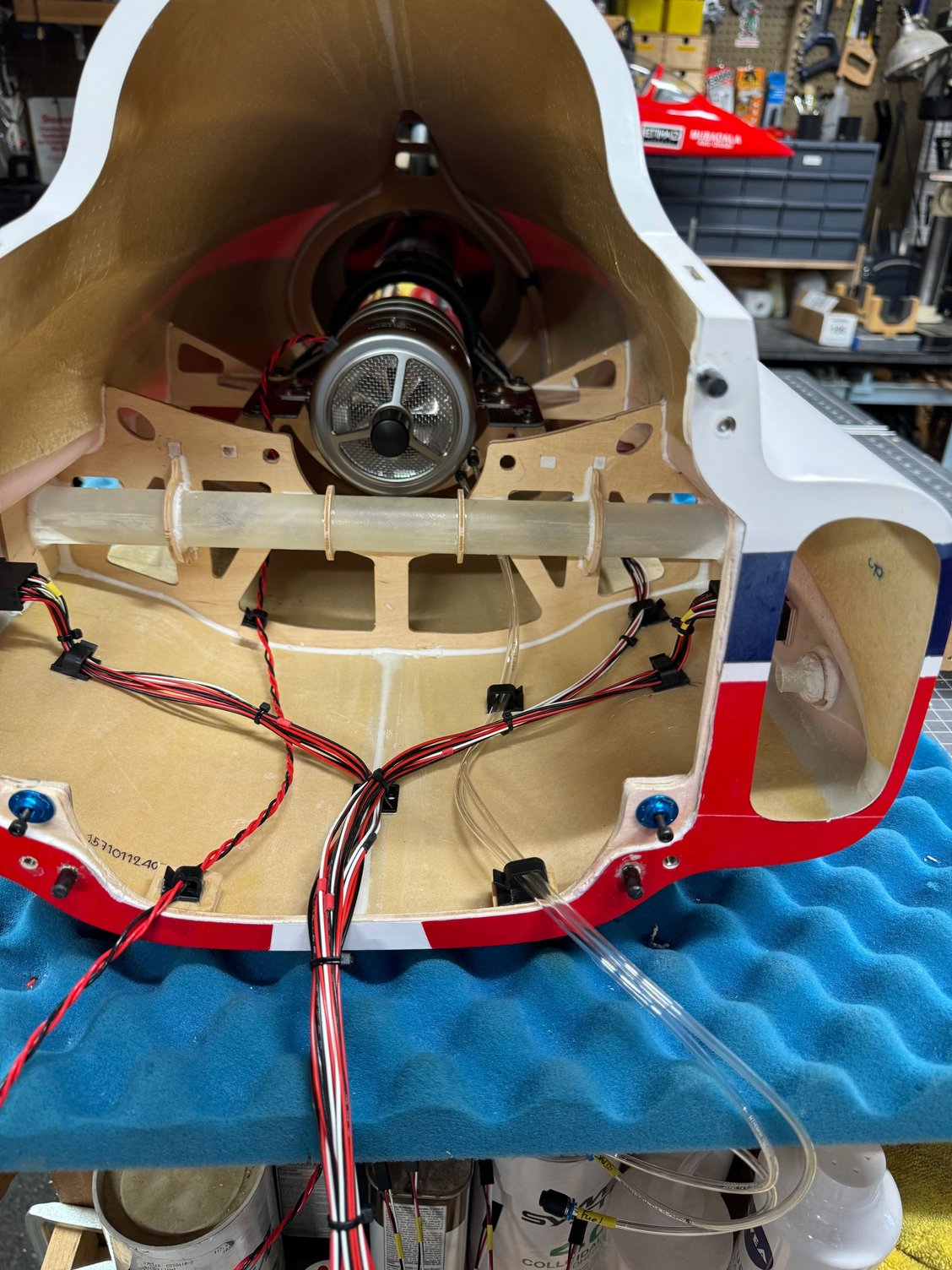

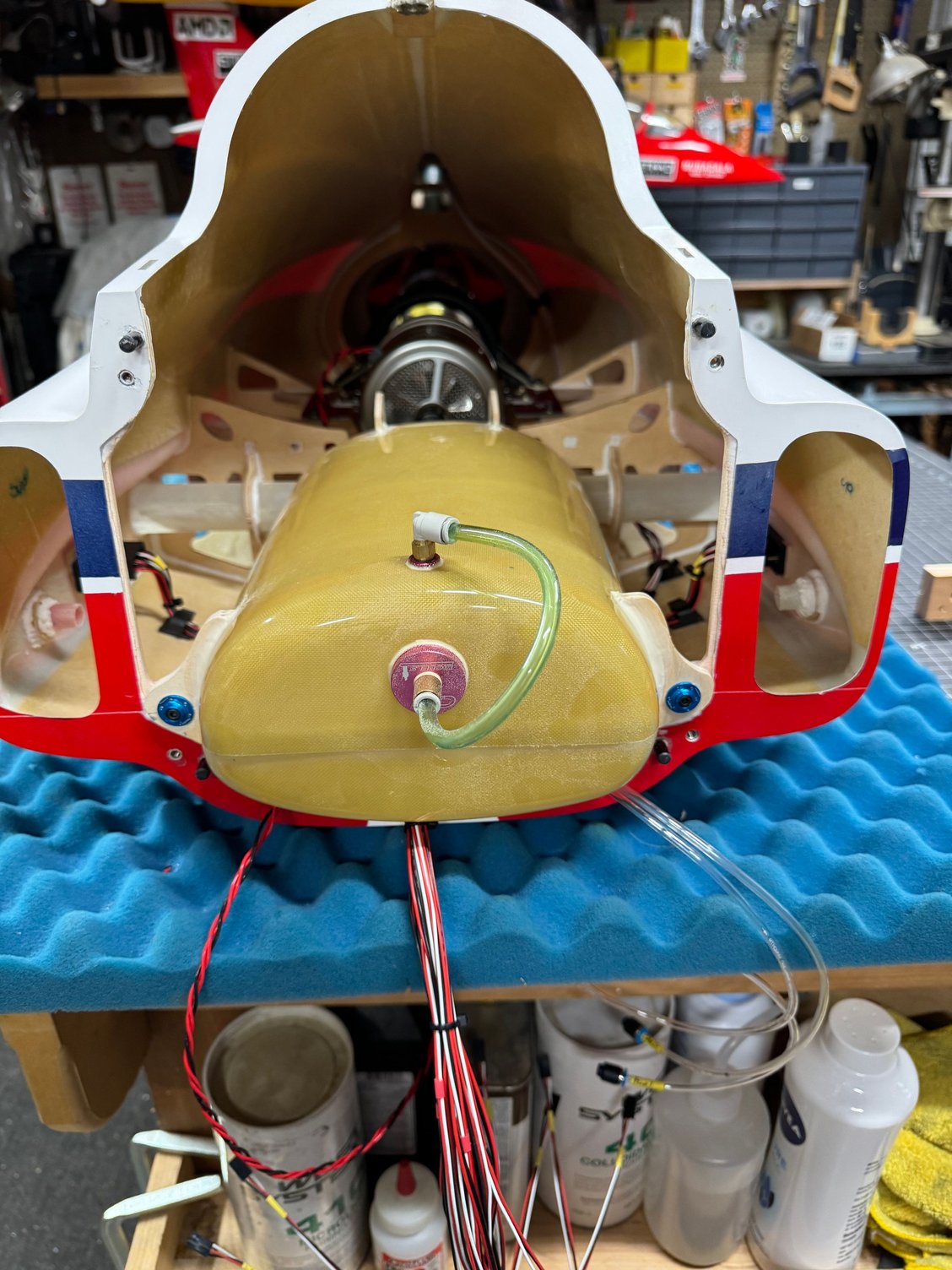

I decided to use a K160-G5 rather than the Cheetah. I put wires in for wing lights but have not decided if I will do that. I'm on the fence about a cockpit. I will lightly tint the canopy and decide later.

The next step is figuring out how to install the batteries.

I figure gluing the main canopy on before the front part is the smartest way to go. I can reach thru the front to put the magnets in while the canopy frame is taped down.

I decided to use a K160-G5 rather than the Cheetah. I put wires in for wing lights but have not decided if I will do that. I'm on the fence about a cockpit. I will lightly tint the canopy and decide later.

The next step is figuring out how to install the batteries.

I figure gluing the main canopy on before the front part is the smartest way to go. I can reach thru the front to put the magnets in while the canopy frame is taped down.